2-1

2.1 Mechanical Operating Principles

2.1.1

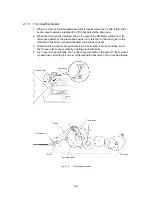

Description of Mechanisms (Border Mode)

1. When a document is inserted into the paper loading gate, the paper feed rollers feed

it to the driving roller.

2. As the document passes between the paper feed rollers, the paper size detector

determines its size (length and width).

3. When the document passes between the film cartridges it is sandwiched between

the upper and lower films in the compression-feed area, where the films and

document are compressed between the driving roller and sub-roller.

4. The compressed document and film is fed to the cutting area, where it is cut to the

document size detected by the paper size detector with borders added. It is then

transported to the next stage.

5. The laminated document is fed out of the eject gate by the paper eject rollers.

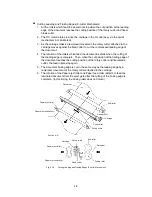

Eject gate

Y-cutter blade

Paper eject roller

X-cutter unit

Paper eject sub-roller

Ejecting area

Sub-roller

Film cartridge

Cutting area

Driving roller

Compression-feed area

Roll film (lower)

Paper feed roller

Paper loading area

Paper length detector

Paper loading gate

Paper width detector

Paper feed

sub-roller

Roll film (upper)

Fig. 2.1-1

Description of Mechanisms

Summary of Contents for LX-1200

Page 1: ...SERVICE MANUAL MODEL LX 1200 LX 300 ...

Page 2: ...COOL LAMINATOR SERVICE MANUAL MODEL LX 1200 LX 300 ...

Page 5: ...Chapter 1 SPECIFICATIONS ...

Page 9: ...Chapter 2 MECHANISMS ...

Page 20: ...Chapter 3 DISASSEMBLY PROCEDURES ...

Page 58: ...Chapter 4 ASSEMBLY PROCEDURES ...

Page 105: ...Chapter 5 ELECTRONIC CONTROLLERS ...

Page 127: ...Chapter 6 MAINTENANCE ...

Page 149: ...Chapter 7 TROUBLESHOOTING ...