7-11

5

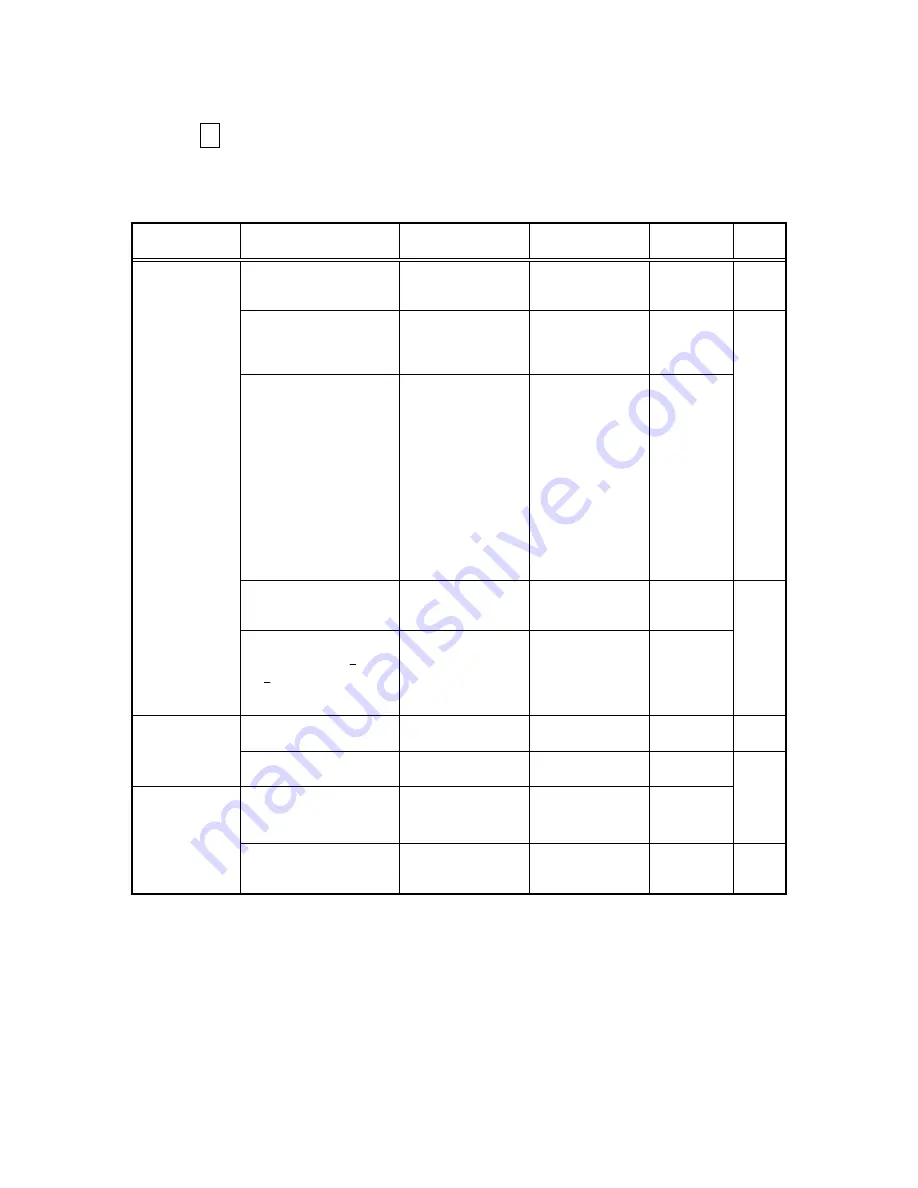

Abnormal manual feed

a. Defective film feed (LF) motor.

b. Defective film compression system.

c. Problem related to paper eject roller.

Problem Check

Item

Cause Remedy

Repair

See

Section

Is the black lead connector

connected to CN12 on the

Main PCB?

Motor harness assy

not connected.

Correctly connect

the motor harness

assy.

3.3.3

3.3.4

3.3.5

Are pulses output from

output ports P01 to P04 (Pin

66 to Pin 69) of the main

CPU#3?

Defective main

CPU#3.

Replace Main PCB

assy.

Replace

CPU#3.

During High output of the

Main CPU #3 output ports

P02 and P03 (Pins 67, 68)

when the outputs of P01

and P64 (Pins 66, 69) are

Low and the output of either

or both P05 and P00 (Pins

70 and 65) is Low, are the

driver #6 OUT 1 (Pin 9) and

OUT 4 (Pin 19) outputs

approximately 24 V and the

OUT 2 (Pin 11) and OUT 3

(Pin 15) outputs

approximately 0 V?

Defective driver #6.

Replace Main PCB

assy.

Replace #6.

3.3.3

3.3.4

3.3.5

3.4.2

3.5.1

Conductivity in motor

harness assy?

Defective motor

harness assy.

Replace motor

harness assy for LF

motor.

a. Defective film

feed (LF)

motor

Is the resistance value

correct (approx. 5.5 ohms)

between phases A-

A

and

B-

B

of the LF motor (PM

motor L)?

Defective LF motor.

Replace LF motor.

3.3.1

3.3.3

3.3.4

3.3.5

3.4

Are top and bottom feed

rollers correctly engaged?

Roller holder unit is

incorrectly set up.

Correctly set up the

roller holder unit.

6.2

b. Defective film

compression

system.

Is film correctly placed

between the feed rollers?

Defective cassette

setting.

Set the cassette

correctly.

Film or other foreign matter

stuck to top or bottom paper

eject roller.

Foreign matter stuck

to roller.

Clean off foreign

matter.

3.3.1

3.3.3

3.3.4

3.3.5

3.4

3.13

c. Problem

related to

paper eject

roller

Do the top and bottom

paper eject rollers move

smoothly?

Problem with paper

eject rollers.

Apply KS64F silicon

grease to the four

bearings.

Summary of Contents for LX-1200

Page 1: ...SERVICE MANUAL MODEL LX 1200 LX 300 ...

Page 2: ...COOL LAMINATOR SERVICE MANUAL MODEL LX 1200 LX 300 ...

Page 5: ...Chapter 1 SPECIFICATIONS ...

Page 9: ...Chapter 2 MECHANISMS ...

Page 20: ...Chapter 3 DISASSEMBLY PROCEDURES ...

Page 58: ...Chapter 4 ASSEMBLY PROCEDURES ...

Page 105: ...Chapter 5 ELECTRONIC CONTROLLERS ...

Page 127: ...Chapter 6 MAINTENANCE ...

Page 149: ...Chapter 7 TROUBLESHOOTING ...