73

How to Work

●

How to Inspect

1. Inspecting the safety switch for the parking

brake pedal .

2. With the parking brake pedal in the “Unlocked”

position,

turn the engine switch to the “ ”

position.

3. With the parking brake pedal in the “Locked”

position, turn the engine switch to the “ ”

position.

○

If the safety switch is working properly, the engine

will not start.

×

If the engine starts, make the necessary adjustment.

○

If the safety switch is working properly, the engine

will start.

×

If the engine does not start, make the necessary

adjustment.

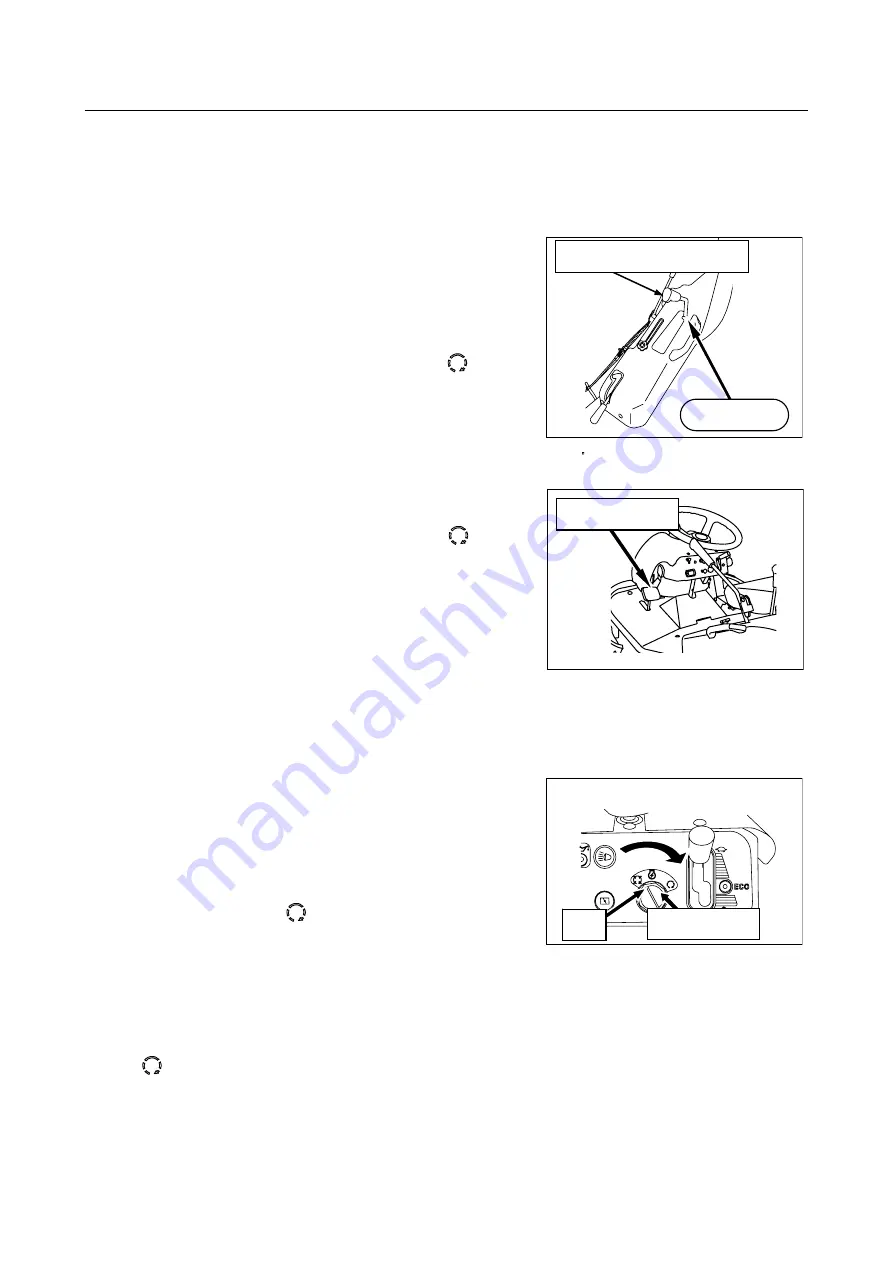

(1)Inspecting the safety switch for the parking brake pedal

1. While sitting on the seat, depress the parking

brake pedal up to the “Locked” position.

2. With the cutting-height adjustment lever in a

position other than “Start Engine”, turn the en-

gine switch to the “ ” position.

3. With the cutting-height adjustment lever in the

“ ” position.

○

If the safety switch is working properly, the engine

will start.

×

If the engine starts, make the necessary adjustment.

○

If the safety switch is working properly, the engine

will start.

×

If the engine starts, make the necessary adjustment.

(2)Inspecting the safety switch for the cutting blade

Cutting-height adjustment lever

Start engine

Brake pedal

STOP

Key

Engine switch

While sitting on the seat, shift the cutting-height

adjustment lever to the “Start Engine” position.

Summary of Contents for AR950

Page 105: ......

Page 106: ...0675 944 011 0 ATEX CO LTD 1 2 5 Kinuyama Matsuyama Ehime 791 8524 Japan...