APPENDIX F: BASICS OF RESISTANCE WELDING

HF25D LINEAR DC RESISTANCE WELDING CONTROL

F-4

990-333

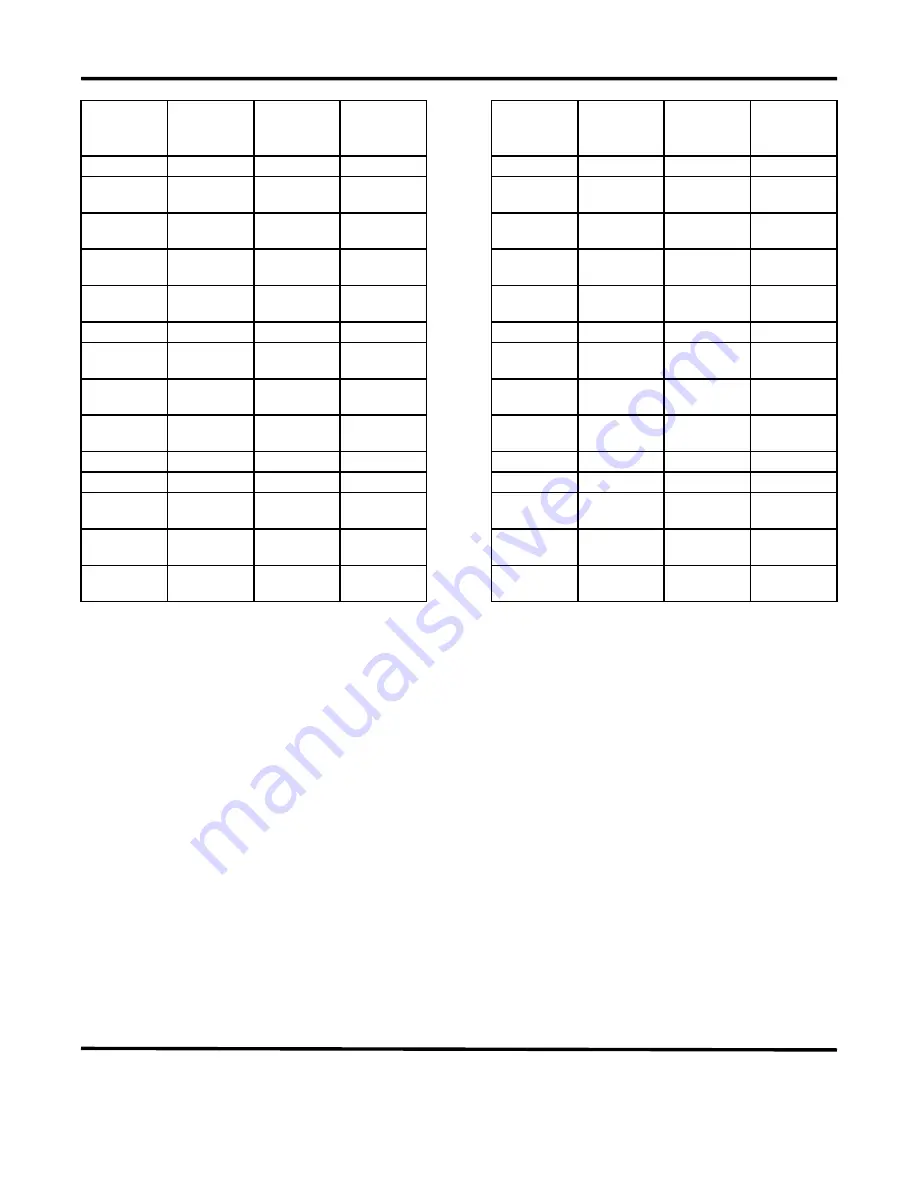

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

Gold -14

Gold -14

Nickel

Alloy

-2

Nichrome

-2

Nickel Alloy

-2

Nickel

-2

Cold Rolled

Steel

-2 Stainless

Steel

-2

Nickel Alloy

-2

Cold Rolled

Steel

-2

NiSpan C

-2

NiSpan C

-2

Hastalloy

-2 Titanium

-2

NiSpan

C

-2 Cold

Rolled

Steel

-2

Inconel -2

Inconel -2

NiSpan

C

-2

Stainless

Steel

-2

Inconel

-2 Kulgrid

-2

Niobium

-2 Niobium

-2

Invar -2

Invar -2

Cold

Rolled

Steel

-2 Tantalum

-2

Platinum -2

Platinum -2

Stainless

Steel

-2 Stainless

Steel

-2

Paliney 7

-2

Paliney 7

-2

Stainless

Steel

-2 Tungsten

-2

Silver -11,

-14

Silver -11,

-14

Tantalum -2

Tantalum -2

Silver -11,

-14

Cadmium -13

Titanium -2

Titanium -2

Silver

-11, -14

Cold Rolled

Steel

-2

Tungsten -2

Tungsten -2

Silver -11,

-14

Stainless

Steel

-2

Tungsten

-2 henium

-2

Cold Rolled

Steel

-2 Cold

Rolled

Steel

-2

Zinc -14

Zinc -14

Electrode Maintenance

Depending on use, periodic tip resurfacing is required to remove oxides and welding debris from

electrodes. Cleaning of electrodes on production line should be limited to use of #400-600 grit electrode

polishing disks. For less critical applications, a file can be used to clean a badly damaged tip. However,

after filing, polishing disks should then be used to ensure that the electrode faces are smooth. If this is

not done, the rough surface of the electrode face will have a tendency to stick to the work piece.

Weld Schedule Development

Developing a weld schedule is a methodical procedure, which consists of making sample welds and

evaluating the results. The first weld should be made at low energy settings. Adjustments are then

made to each of the welding parameters

one at a time

until a successful weld is made.

1

Install the correct electrodes in the electrode holders on the Weld Head. See the preceding

Table for electrode material recommendations.

Содержание HF25A

Страница 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Страница 10: ......

Страница 20: ......

Страница 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Страница 113: ......

Страница 129: ......

Страница 153: ......

Страница 171: ......