APPENDIX G: DEFINING THE OPTIMUM PROCESS

HF25D LINEAR DC RESISTANCE WELDING CONTROL

990-333

G-6

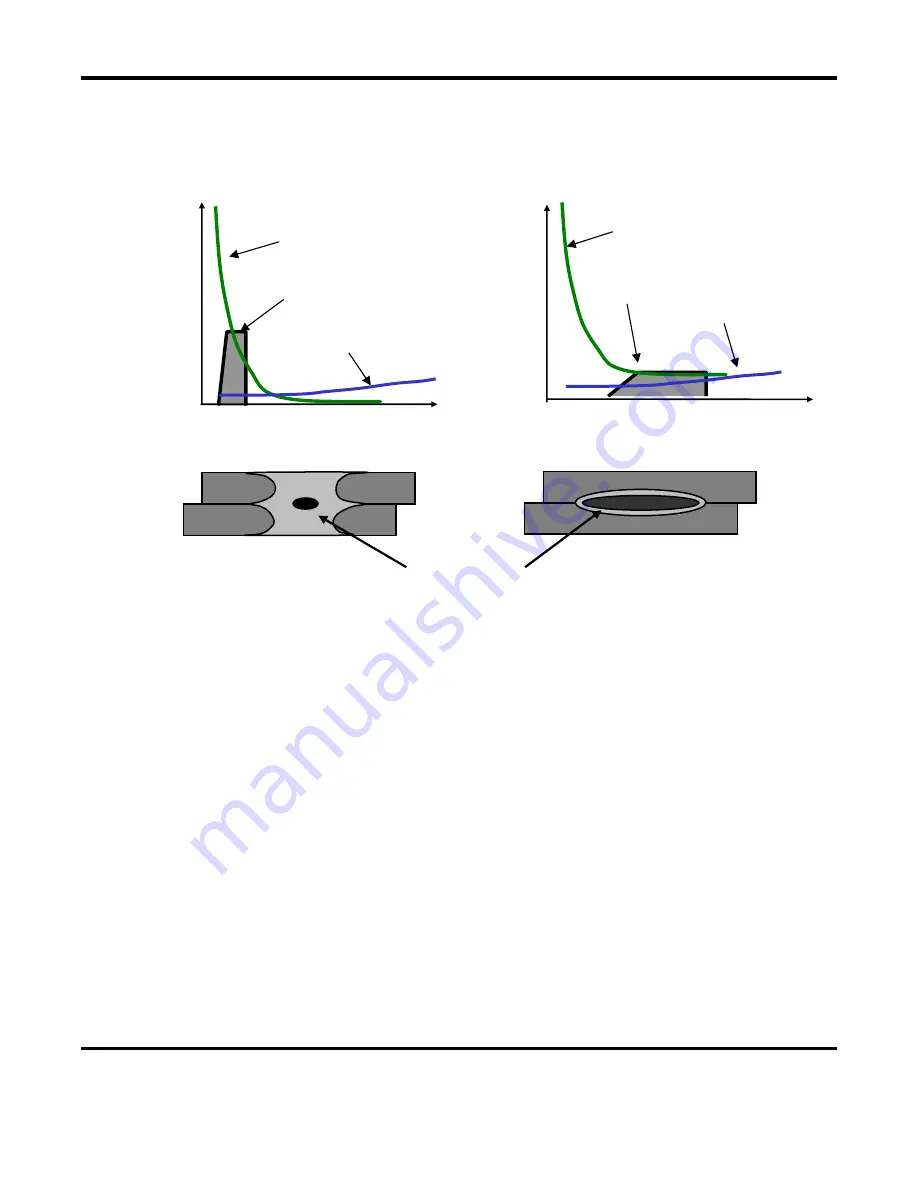

The figure below shows a weld that is fired

early on in the weld sequence when the

contact resistance is still quite high.

The figure below shows a weld that is initiated

when the contact resistance is lower and in this

example we are using bulk resistance to generate

our weld heat.

In general conductive materials benefit from a faster heating rate, as the higher contact resistances assist

heat generation in the weld. Resistive materials benefit from slower heating rates that allow the contact

resistances to reduce significantly thus bulk resistances become the major source for heat generation.

Weld Profiles

The basic welding profile or schedule consists of a controlled application of energy and force over time.

Precision power supplies control the energy, time, and therefore heating rate of the parts. The weld head

applies force from the start to finish of the welding process.

Time

Bulk Resistance

Resistance

Contact Resistance

Weld Pulse

Heat Affected Zone

(NOTE: Larger nuggets are possible with longer weld times when using bulk resistance.)

Resistance

Bulk Resistance

Time

Contact Resistance

Weld Pulse

Содержание HF25A

Страница 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Страница 10: ......

Страница 20: ......

Страница 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Страница 113: ......

Страница 129: ......

Страница 153: ......

Страница 171: ......