HF25D DC RESISTANCE WELDING SYSTEM

990-333

6-1

CHAPTER 6

CALIBRATION

Calibration

The calibration procedure is initiated at the main menu, as described in

Chapter 3, Using Programming

Functions, Section I, Menus. .

The Control is calibrated by the software, using inputs from a calibration

setup during a weld process. Following a few calibration inputs, the Control will adjust itself and store

the calibration values in RAM, where they will be used as standards for the operational welding

parameters.

CAUTION:

Only authorized personnel should perform this procedure.

Calibration Equipment Required

The required equipment for the setup is as follows:

•

2 weld cables, No. 2/0, 1 ft (30 cm) long, PN 2/0 BB11

•

1000µ

Ω

coaxial shunt resistor accurate to ±0.2%.

Source for shunt resistor: Model R7500-8

T & M Research Products, Inc.

139 Rhode Island Street NE

Albuquerque,

NM

87108

Telephone: (505) 268-0316

•

Shielded voltage sense cable, PN 4-32998-01

•

Digital oscilloscope, Tektronix 724C or equivalent

•

Male BNC to dual binding post

•

2-wire, normally open switch for weld initiation, mating connector PN 520-011

•

Coaxial BNC-to-BNC cable

NOTE:

If you are using the optional LVDT, the only equipment required for LVDT

calibration is a piece of metal machined to an

exact known thickness

. This will be

placed between the electrodes as a reference. See

Appendix D, LVDT Option, Section

III, Calibration.

Содержание HF25A

Страница 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Страница 10: ......

Страница 20: ......

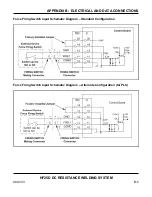

Страница 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Страница 113: ......

Страница 129: ......

Страница 153: ......

Страница 171: ......