APPENDIX F: BASICS OF RESISTANCE WELDING

HF25D LINEAR DC RESISTANCE WELDING CONTROL

F-2

990-333

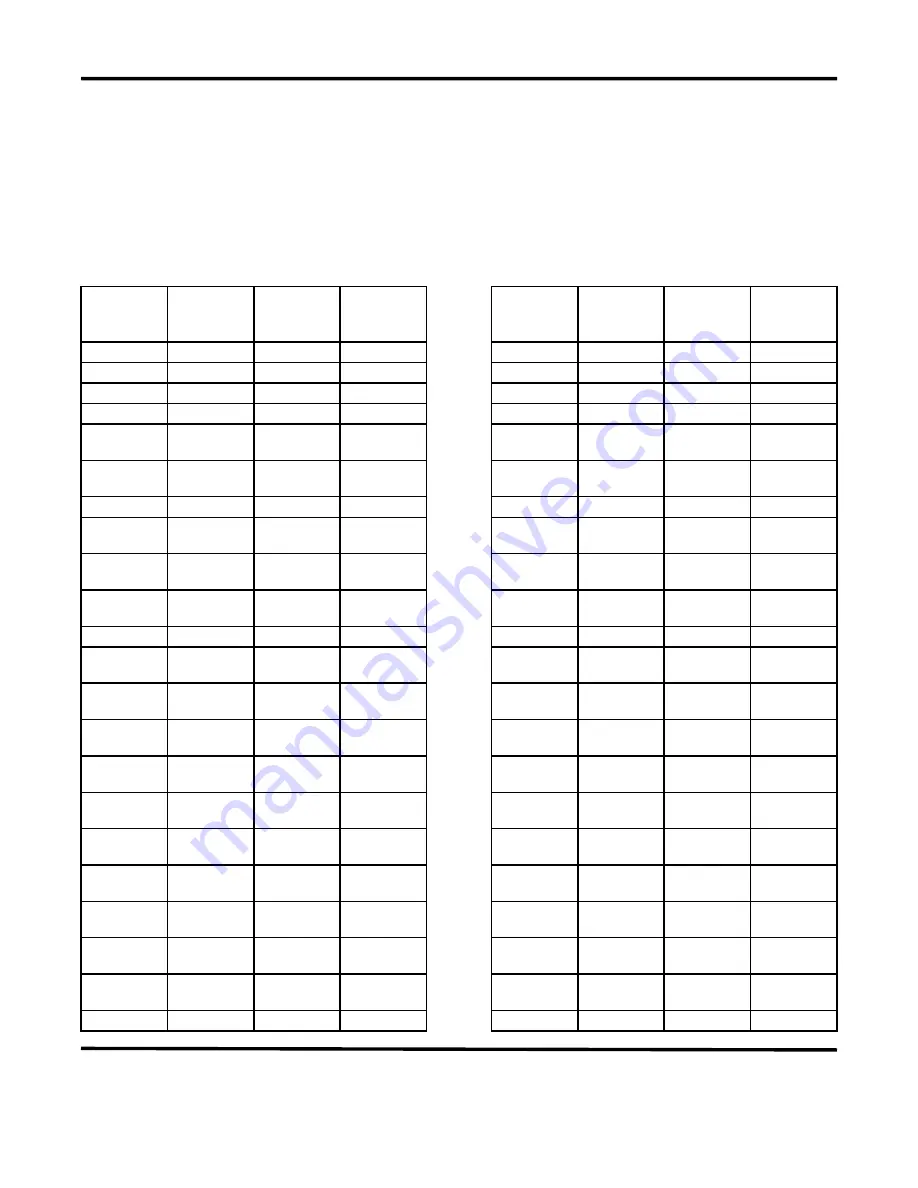

Electrode Selection

Correct electrode selection strongly influences how weld heat is generated in the weld area. In general,

use conductive electrodes such as a RWMA-2 (Copper alloy) when welding electrically resistive parts

such as nickel or steel so that the weld heat is generated by the electrical resistance of the parts and the

contact resistance between the parts. Use resistive electrodes such as RWMA-13 (Tungsten) and

RWMA-14 (Molybdenum) to weld conductive parts such as copper and gold because conductive parts

do not generate much internal heat so the electrodes must provide external heat. Use the following

Electrode Selection Table for selecting the proper electrode materials.

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

MATERIAL

ELECT

RWMA

TYPE

Alumel -2

Alumel -2

Brass -2,

-14

Tinned

Brass

-14

Alumel -2

Chromel -2

Brass -2,

-14

Consil -2

Alumel -2

Dumet -2

Brass -2,

-14

Constantan

-2

Aluminum -1

Aluminum -1

Brass

-2,

-14

Copper

-14

Aluminum -1

Aluminum

Alloys

-1

Brass

-2,

-14 Tinned

Copper

-14

Aluminum -1

Cadmium

Plating

-1

Brass

-2,

-14 Dumet

-2

Aluminum -1

Tinned

Brass

-14

Brass -2,

-14

Nichrome -2

Aluminum -1

Tinned

Copper

-14

Brass

-2,

-14 Nickel

-2

Aluminum -1

Gold

Plated

Dumet

-2

Brass

-2, -14

NiSpan C

-2

Aluminum -1

Gold

Plated

Kovar

-2

Brass

-2, -14

Paliney 7

-2

Aluminum

-1

Kovar

-2

Brass

-2, -14

Silver

-11, -14

Aluminum

-1

Magnesium

-1

Brass

-2, -14

Cold Rolled

Steel

-2

Aluminum -1

Cold

Rolled

Steel

-2

Brass

-2,

-14 Stainless

Steel

-2

Aluminum -1

Stainless

Steel

-2

Bronze

-2, -11

Bronze

-2, -11

Beryllium

Copper

-2 Beryllium

Copper

-2

Bronze

-2,

-11 Tinned

Copper

-14

Beryllium

Copper

-2

Brass

-2, -14

Bronze

-2, -11

Iron

-2

Beryllium

Copper

-2 Copper

-14

Bronze

-2,

-11 Nichrome -2

Beryllium

Copper

-2 Tinned

Copper

-14

Bronze

-2,

-11

Nickel

-2

Beryllium

Copper

-2

Nickel

-2

Chromel -2 Chromel -2

Beryllium

Copper

-2 Cold

Rolled

Steel

-2

Chromel

-2 Constantan -2

Beryllium

Copper

-2 Stainless

Steel

-2

Chromel -2 Copel -2

Brass -2,

-14

Brass -2,

-14

Chromel -2

Copper

-14

Содержание HF25A

Страница 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Страница 10: ......

Страница 20: ......

Страница 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Страница 113: ......

Страница 129: ......

Страница 153: ......

Страница 171: ......