Hardware configuration.

CNC 8070

CENTRAL

UNIT + MONITO

R (ETX PLATFORM).

5.

Conn

ecti

ons.

·89·

(R

EF

: 1911)

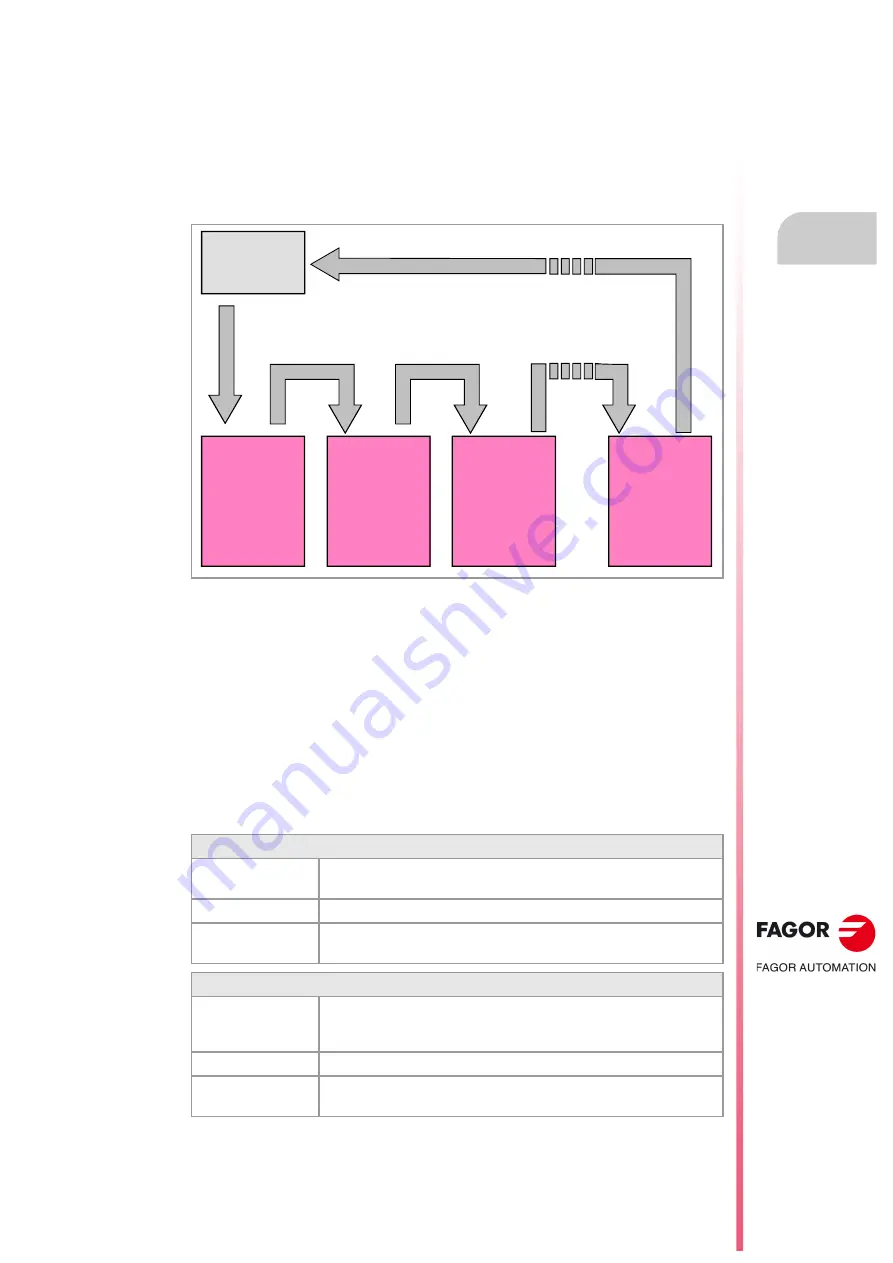

5.12.7 Sercos II bus.

The Sercos interface is a communications standard especially designed for the machine-

tool industry offering a simple interface between the CNC and the drives. All the data and

commands are transmitted in digital format through fiber optic lines that make up a ring (the

Sercos ring) that connects all the elements of the bus (CNC and drives) to each other. Using

the Sercos interface considerably minimizes the necessary hardware, makes cabling

simpler and grants greater reliability to the system making it immune to electrical interference

(noise).

Sercos cable characteristics.

Fagor Automation provides the fiber optic cables needed for Sercos communication. There

are different types of cables depending on length and dynamic and static installation

characteristics.

• Fiber optic cable with polymer core (SFO, SFO-FLEX) for up to 40 meters. If the fiber

optic cable is going to withstand dynamic conditions (moving), always use the SFO-FLEX

cable If the cable will be subject to static conditions (it will not be moving), the SFO cable

will be enough.

• Fiber optic cable with glass core (SFO-V-FLEX) for over 40 meters.

Mechanical characteristics of the cables.

SFO cable.

Flexibility.

Normal. Minimum bending radius of 30 mm.

Only to be used when the cable will not be moving (static conditions).

Covering.

PUR. Polyurethane resistant to chemical used on machines.

Temperature.

Work: -20 ºC / 80 ºC (-4 ºF / 176 ºF).

Storage: -35 ºC / 85 ºC (-31 ºF / 158 ºF).

SFO-FLEX cable.

Flexibility.

High. Minimum static bending radius of 50 mm and a dynamic radius of 70

mm.

Special cables to be used in cable carrying chains.

Covering.

PUR. Polyurethane resistant to chemical used on machines.

Temperature.

Work: -20 ºC / 70 ºC (-4 ºF / 158 ºF).

Storage: -40 ºC / 80 ºC (-40 ºF / 176 ºF).

CNC

DRIVE

1

DRIVE

2

DRIVE

3

DRIVE

n

Содержание CNC 8070

Страница 1: ...Ref 1911 8070 CNC Hardware configuration...

Страница 8: ...BLANK PAGE 8...

Страница 14: ...BLANK PAGE 14...

Страница 18: ...BLANK PAGE 18...

Страница 22: ...BLANK PAGE 22...

Страница 24: ...BLANK PAGE 24...

Страница 26: ...BLANK PAGE 26...

Страница 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Страница 38: ...Hardware configuration CNC 8070 2 CONFIGURATION General diagram for U60 Q7 A platform 38 REF 1911...

Страница 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Страница 184: ...Hardware configuration CNC 8070 8 LCD 15SVGA PASSIVE MONITOR LCD15 SVGA Overall connection 184 REF 1911...

Страница 272: ...Hardware configuration CNC 8070 18 INSTALLING A SENSOR FOR GAP CONTROL LASER MODEL 272 REF 1911...

Страница 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Страница 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Страница 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...