Hardware configuration.

CNC 8070

CEN

T

RAL UNIT + MONITOR (Q7-A

PLATFORM).

6.

Conn

ecti

ons.

·129·

(R

EF

: 1911)

Bus configuration.

Element connection.

Use an inline topology. Join the B64 connector of the CNC to the X1(IN) connector of the

first header. Connect the other of headers, joining the X2 (OUT) connector of one header

with the X1 (IN) connector of the following one. Do not connect the X2(OUT) connector of

the last header.

In order to ensure proper performance, the connection cable must be inserted all the way

into the connectors so they're latched. This ensures that the cable is properly latched and

does not come off due to vibration.

Module identification.

The node number for each header is not defined on this bus. The node number is assigned

by the configurator on the basis of its designed topology.

Transmission speed.

The transmission speed is 100 MHz. Use a cable having the recommended characteristics

to ensure this speed.

Activate the bus on the CNC.

Activate the bus on the CNC using the machine parameter ETHERCATBUS.

Configuring the EtherCAT bus.

Fagor supplies the configurator “KPA EtherCAT Studio” (by Koening-pa GmbH) under

license, which can operate both online and offline, to define the bus topology and create the

ENI file containing the bus device information. This file must be copied to the folder

../Mtb/Data of the CNC with the name "fagor_ethercatConfFile.xml". This file also uses the

"Fagor EtherCAT Mapper" program for determining the resources available in the bus.

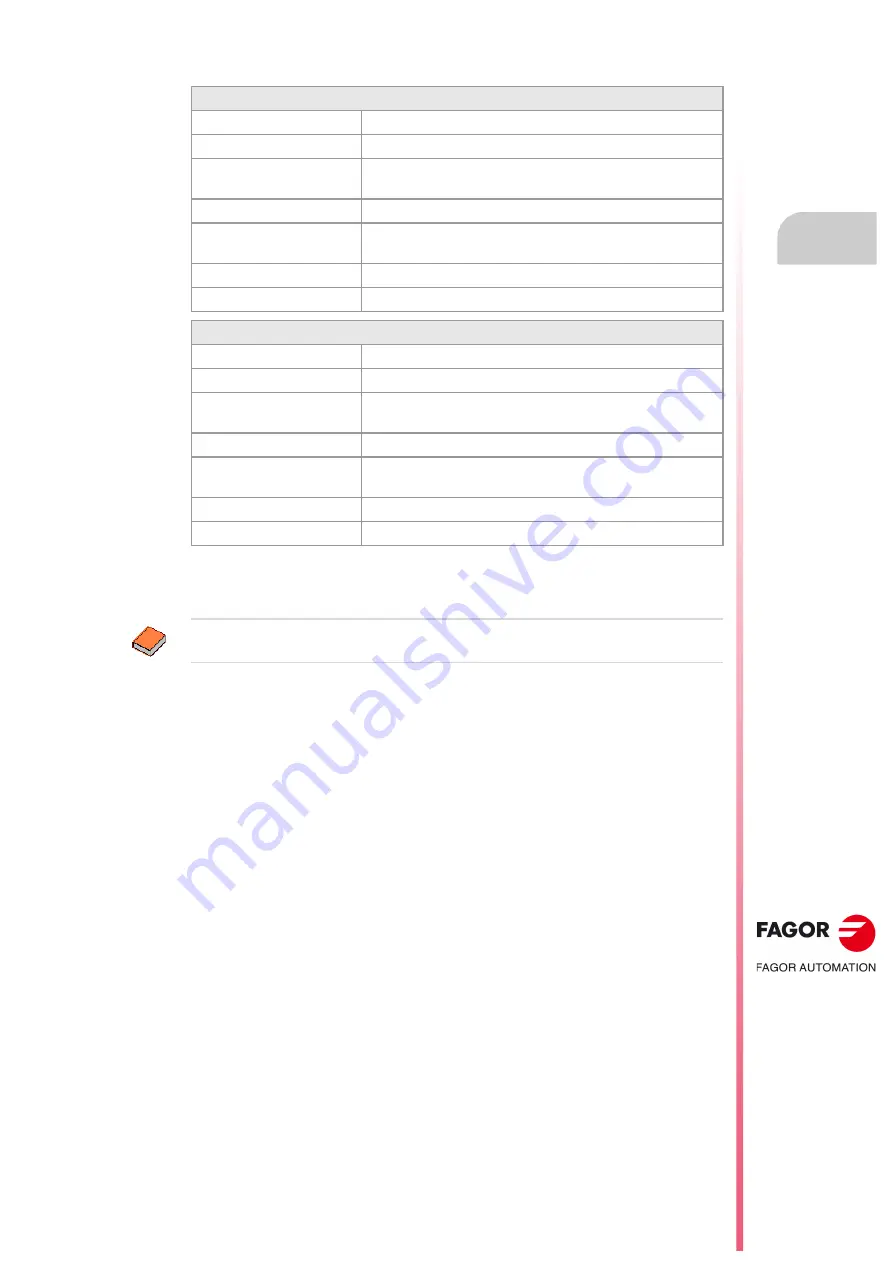

ECAT-CABLE cable

Type.

Industrial Cat 6A shielded 8-wire Ethernet cable (twisted pairs).

Diameter.

6.3 mm - 6.9 mm.

Flexibility.

Minimum static bending radius 4 x diameter.

Minimum dynamic bending radius 8 x diameter.

Covering.

PVC. Polyvinyl chloride.

Temperature.

Work: -20 ºC / 80 ºC (-4 ºF / 176 ºF).

Storage: -20 ºC / 80 ºC (-4 ºF / 176 ºF).

Color.

Yellow, RAL 1021.

Minimum/maximum length.

1 m (3.2 ft) / 7 m (23 ft).

ECAT-CABLE-FLEX cable

Type.

Industrial Cat 6A shielded 8-wire Ethernet cable (twisted pairs).

Diameter.

6.3 mm - 6.9 mm.

Flexibility.

Minimum static bending radius 4 x diameter.

Minimum dynamic bending radius 8 x diameter.

Covering.

PUR. Polyurethane.

Temperature.

Work: -40 ºC / 80 ºC (-40 ºF / 176 ºF).

Storage: -40 ºC / 80 ºC (-40 ºF / 176 ºF).

Color.

Yellow, RAL 1021.

Minimum/maximum length.

10 m (32.8 ft) / 100 m (328 ft).

Refer to the installation manual for further information on installing and using the EtherCAT configurator

and mapper.

Содержание CNC 8070

Страница 1: ...Ref 1911 8070 CNC Hardware configuration...

Страница 8: ...BLANK PAGE 8...

Страница 14: ...BLANK PAGE 14...

Страница 18: ...BLANK PAGE 18...

Страница 22: ...BLANK PAGE 22...

Страница 24: ...BLANK PAGE 24...

Страница 26: ...BLANK PAGE 26...

Страница 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Страница 38: ...Hardware configuration CNC 8070 2 CONFIGURATION General diagram for U60 Q7 A platform 38 REF 1911...

Страница 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Страница 184: ...Hardware configuration CNC 8070 8 LCD 15SVGA PASSIVE MONITOR LCD15 SVGA Overall connection 184 REF 1911...

Страница 272: ...Hardware configuration CNC 8070 18 INSTALLING A SENSOR FOR GAP CONTROL LASER MODEL 272 REF 1911...

Страница 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Страница 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Страница 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...