Hardware configuration.

CNC 8070

7.

CENTRAL U

N

IT

FOR C

ABI

NET (Q7-A

PLATFORM).

Conn

ecti

ons.

·174·

(R

EF

: 1911)

Identification of the first and last elements of the bus. Line

terminating resistor.

In the CAN bus, it is necessary to use a line terminating resistor to identify which are the

elements that occupy the ends of the bus; i.e. the first and last physical element in the

connection. For the central unit, the terminating resistor is factory installed because the CNC

is always at one end of the bus.

Bus type selector: CANfagor / CANopen.

At the CNC, the type of CAN bus is selected by means of the machine parameters (parameter

CANMODE),

Selection of the cable length of the CANfagor bus cable.

Using the CANfagor type bus requires the definition of the maximum length of the bus with

parameter CANLENGTH.

Selecting the speed for the CANopen bus.

When using the CANopen protocol, the transmission speed at the bus is defined in each node

and they all must run at the same speed. The transmission speed depends on the total length

of the bus. Using the following illustrative values; assigning other values may cause

communication errors due to signal distortion.

Selecting the speed at the CNC.

At the CNC, the transmission speed is selected by means of the machine parameters

(parameter CANOPENFREQ).

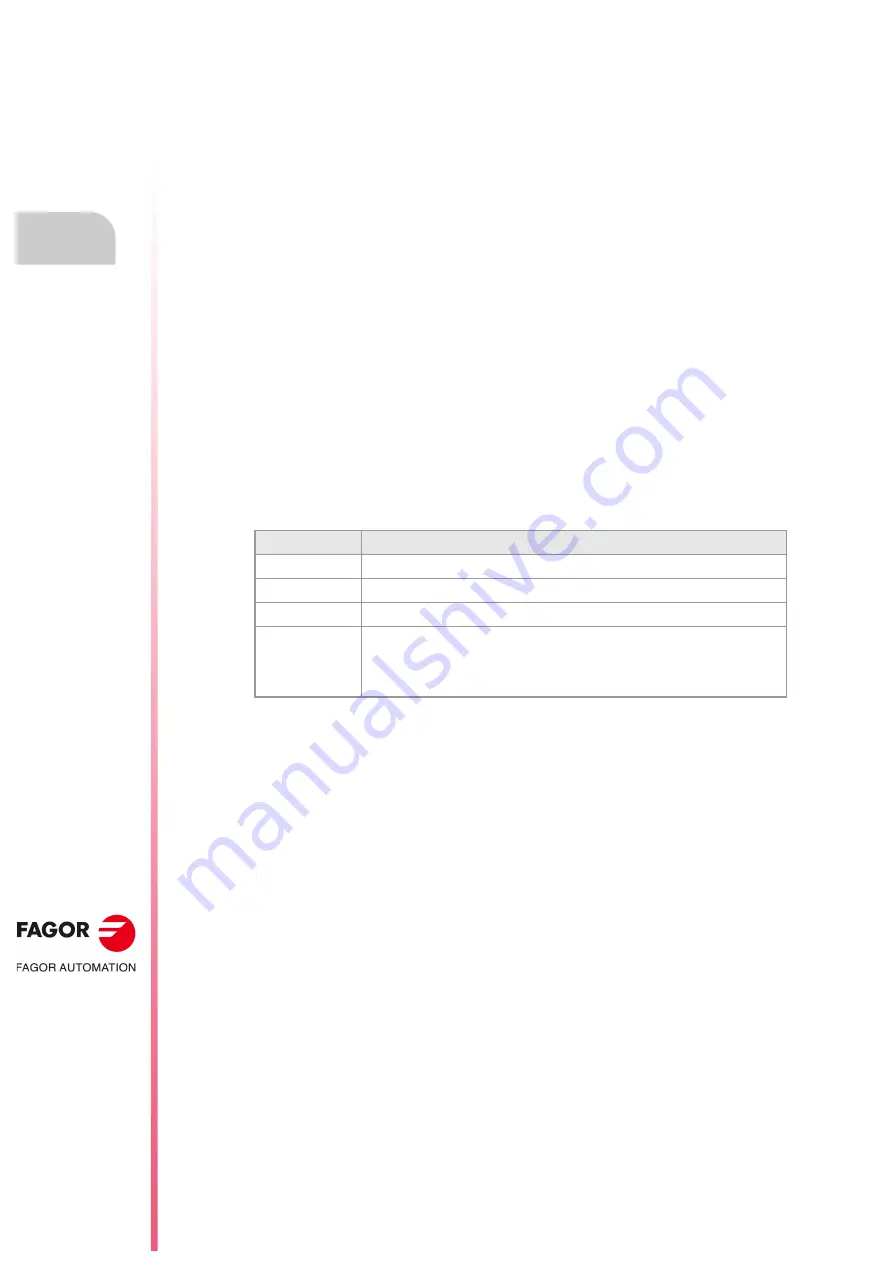

Speed

Length of the CAN bus.

1000 kHz

Up to 20 meters.

800 kHz

From 20 to 40 meters.

500 kHz

From 40 to 100 meters.

250 kHz

From 100 to 500 meters.

The speed of 250 kHz is only available to communicate with the keyboards and

RIOW and RIOR series remote modules; this speed is not available for the RIO5

series remote modules.

Содержание CNC 8070

Страница 1: ...Ref 1911 8070 CNC Hardware configuration...

Страница 8: ...BLANK PAGE 8...

Страница 14: ...BLANK PAGE 14...

Страница 18: ...BLANK PAGE 18...

Страница 22: ...BLANK PAGE 22...

Страница 24: ...BLANK PAGE 24...

Страница 26: ...BLANK PAGE 26...

Страница 28: ...Hardware configuration CNC 8070 1 PREVIOUS INFORMATION 28 REF 1911...

Страница 38: ...Hardware configuration CNC 8070 2 CONFIGURATION General diagram for U60 Q7 A platform 38 REF 1911...

Страница 94: ...Hardware configuration CNC 8070 6 CENTRAL UNIT MONITOR Q7 A PLATFORM 94 REF 1911 C70 15AT...

Страница 184: ...Hardware configuration CNC 8070 8 LCD 15SVGA PASSIVE MONITOR LCD15 SVGA Overall connection 184 REF 1911...

Страница 272: ...Hardware configuration CNC 8070 18 INSTALLING A SENSOR FOR GAP CONTROL LASER MODEL 272 REF 1911...

Страница 273: ...Hardware configuration CNC 8070 273 User notes REF 1911...

Страница 274: ...Hardware configuration CNC 8070 274 User notes REF 1911...

Страница 275: ...Hardware configuration CNC 8070 275 User notes REF 1911...