1

2

C0..7

I0

4 I2

3 I1

5 I3

6

7 I5

8 I6

9 I7

I4

24 V

DC/AC

+ / ~

– / ~

24 V

DC/AC

+ / ~

– / ~

1

2

C0..7

I0

4 I2

3 I1

5 I3

6

7 I5

8 I6

9 I7

I4

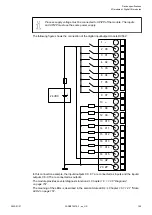

Connection of DI561 - sink inputs

Connection of DI561 - source inputs

The module provides several diagnosis functions

Chapter 1.6.1.1.3.6 “Diagnosis”

The meaning of the LEDs is described in the section State LEDs

I/O Configuration

The module itself does not store configuration data. It receives its parameterization data from

the master device of the I/O bus (CPU or communication interface module) during power-up of

the system.

Hence, replacing I/O modules is possible without any re-parameterization via software.

If the external power supply voltage via UP/ZP terminals fails, the I/O module

loses its configuration data. The whole station has to be switched off and on

again to re-configure the module.

Parameterization

The arrangement of the parameter data is performed with Automation Builder software.

The parameter data directly influences the functionality of modules.

For non-standard applications, it is necessary to adapt the parameters to your system configura-

tion.

Name

Value

Internal

Value

Internal

Value,

Type

Default

Min.

Max.

EDS Slot

Index

Module ID Internal

6105

1

)

WORD

6105

0x17D9

0

65535

xx01

Ignore

module

No

Yes

0

1

BYTE

No (0x00)

Parameter

length

2

)

Internal

1 - CPU

BYTE

0

0

255

xx02

3

)

1

) with CS31 and addresses smaller than 70, the value is increased by 1

Device specifications

I/O modules > Digital I/O modules

2022/01/31

3ADR010278, 3, en_US

164