198

CHAPTER 6 - DETAILED PARAMETER DESCRIPTION

This feature prevents the motor from operating permanently at speeds

where the mechanical system enters into resonance, causing high

vibration or noise levels.

The passage through the skip speed band (2 x P306) is made at the

programmed acceleration/deceleration rates.

This function does not operate properly when two skip speeds are

overlapped.

Range

[Factory Setting]

Parameter

Unit

Description / Notes

P308

(1)

1 to 30

Serial Address

[ 1 ]

-

Sets the address of the inverter for the serial communication. Refer to

item 8.13.

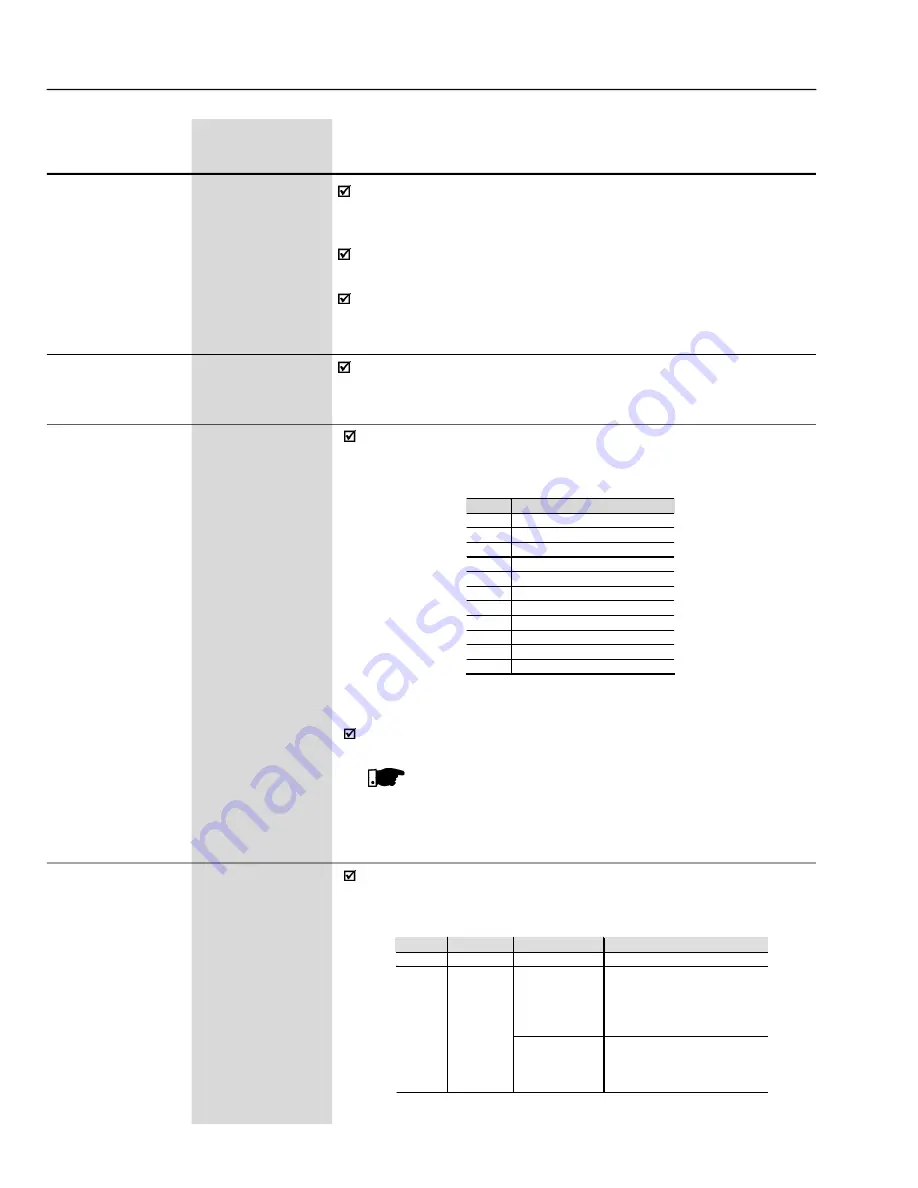

Defines the Fieldbus standard to be used (Profibus DP/DP-V1,

DeviceNet, EtherNet/IP or DeviceNet Drive Profile) and the number of

variables to be exchanged with the master. Refer to item 8.12.7.

P309

(1)

0 to 10

Fieldbus

[ 0 ]

-

It’s only applicable if an optional Fieldbus communication kit were used.

Table 6.49

- Fieldbus options

P309

Fieldbus Options

0

Inactive

1

Profibus DP/DP-V1 2 I/O

2

Profibus DP/DP-V1 4 I/O

3

Profibus DP/DP-V1 6 I/O

4

DeviceNet 2 I/O

5

DeviceNet 4 I/O

6

DeviceNet 6 I/O

7

EtherNet/IP 2 I/O

8

EtherNet/IP 4 I/O

9

EtherNet/IP 6 I/O

10

DeviceNet Drive Profile

NOTE!

If the PLC1 or PLC2 boards are used, the parameter P309

must be programmed as inactive.

P310

(1)

0 or 1

STOP Detection in a

[ 0 ]

Profibus Network

-

This parameter allows programming the bit #6 of the Fieldbus control

word (refer to item 8.12.7.2 - Variable Written in the Inverter).

Table 6.50 -

STOP detection in a Profibus network

P310

Function

Bit #6

CFW-09 Action

0

Off

No function

-

If bit6 = 0

Executes a General

Disable command,

regardless of the value of

the remaining bits of the

control word.

1

On

If bit6 = 1

Executes the commands

that were programmed at

the remaining bits of the

control word.