277

CHAPTER 8 - CFW-09 OPTIONS AND ACCESSORIES

8.11 THROUGH SURFACE

MOUNTING KIT

The kit for through surface mounting is composed of metallic supports that

must be mounted on the rear of the CFW-09 frames 3 to 8 to allow through

surface mounting. For further information refer to item 3.1.3.3, figure 3.4 and

table 3.4. Degree of protection is NEMA 1/IP20.

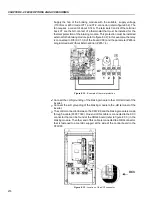

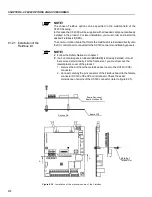

Figure 8.34 shows the connection of the braking module to the inverter, as

well as the connections of the resistor to the braking module. It shows also

the inclusion of a thermal relay and a thermostat in contact with the resistor

body, thus ensuring its thermal protection. The connection cables between

the inverter and the module and between the module and the braking resistor

must be dimensioned according to the thermal braking cycle.

Figure 8.34

- Connections between the DBW, the CFW-09 and the braking resistor

Contactor

XC3

Control

Supply

Thermostat

Thermal

Relay

Braking

Resistor

CFW-09

8.12 FIELDBUS

CFW-09 can be connected to Fieldbus networks allowing its control and

parameter setting. For this purpose you need to include an optional electronic

board according to the desired Fieldbus standard: Profibus DP, DeviceNet or

EtherNet/IP.

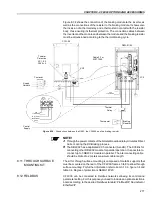

Supply

Network

R

S

T

Fan

110 or 220 V

XC3

DBW-01/02

Cable 2.3 m

0307.7560

Thermal

Protection

XC1: 9.3

P265 = 4

DIx (CC9)

No External

Fault

Fan

110 or 220 V

NOTE!

Through the power contacts of the bimetallic overload relay circulates Direct

Current during the DC-Braking process.

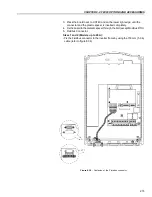

The DBW-02 has a duplicated XC3 connector (A and B). The XC3B is for

connecting other DBW-02 module for parallel operation. It is possible to

connect up to 3 DBW-02 modules in parallel. The interconnecting cable

should be limited to 2 meters maximum cable length.