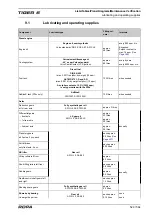

Lists/Tables/Plans/Diagrams/Maintenance Verification

Lubrication schedule for RR 6-row lifter

536 / 564

Lubricating point

Number of

nipples

Every

oper. hrs.

Machine

Knuckle joints of the steering knuckles of the portal axle

4

200

Knuckle joints of the steering knuckles of the rear axles

8

200

Ball bearing activation shaft brake valve

2

500

Upper lever artic. rotation point middle (only with option

additional chassis preparation)

1

500

Universal joint of cardan shafts:

Cardan shafts of the front axle to cardan intermediate

shaft

4

200

Cardan intermediate bearing rigid (over strainer wheel 1)**

1

500

Cardan shaft from intermediate cardan bearing to rear

2

200

Intermediate cardan shaft to front reduction gears

1

200

Cardan shaft from reduction gears to CVR gearbox

2

200

Cardan shaft from reduction gears to 3rd axle

2

200

* Grease with copper paste!

** 3 strokes of the grease gun

ADVICE

All lubricating points must also be lubricated after each washing of the machine. After

washing of the machine, the central lubrication system must also be lubricated using

at least 2 intermediate lubrication cycles.

Grease ROPA item no. 435006200

as per DIN 51825, NLGI-class 2, type: KP2K-20,

at low outdoor temperatures KP2K-30.

No lubricating greases containing solid lubricants may be employed. Biologically

degradable greases are also admissible.

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...