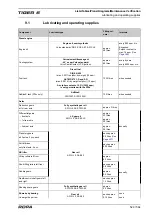

Malfunction and Remedies

Checklist for optimising the lifting quality

525 / 564

Root fracture

– Lift deeper

– Reduce damaged beet lifting speed

– Check/replace lifting shares

– Reduce infeed conveyor rpm

– Reduce strainer wheel rpm

– Set sliding ring on pig tails downwards

– Install sliding grids instead of pig tails

– Reduce unloading height

Too much soil tare

– Lift flatter

– Increase shaking share rotational speed

– Reduce lifting speed

– Set roller position higher

– Increase the distance between guide grids and

strainer wheels

– Increase strainer wheel rpm

– Set sliding ring on pig tails upwards

– Install pig tails instead of sliding grids

Lost beets

On lifting unit:

– Increase share distance

– Set share angle flatter

– Set roller position lower

– Check the guide rods on the share body (lost/broken)

– Install larger lifting shafts (Ø) if the beets are very

small

– Reduce infeed conveyor – lifting shaft – strainer

wheels distance/height

On the cleaning unit:

– Reduce infeed conveyor – lifting shaft – strainer

wheels distance/height

– Check strainer wheel pig tails (lost/broken)

– Reduce the distance between guide grids and strainer

wheels

– Reduce distance between inner grids and strainer

wheel

For machines with rubber-defoliator

In the case of lifting faults check/change the settings in the following sequence:

Remaining beet leaves

– Set combined shaft/cleaning shaft deeper

– Increase combined shaft/cleaning shaft rpm

– Reduce lifting speed

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...