Operation

Lifter

255 / 564

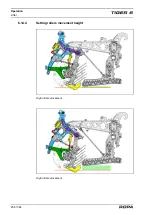

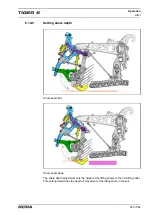

6.14.3

Setting lifting depth

As already mentioned several times, ROPA cannot give any generally applicable rec-

ommendations for such work. Experience and specialist agricultural knowledge of

the driver are decisive for the lifting results, because the machine setting exclusively

depends on local conditions.

The lifting depth should be set so that the sugar beets are lifted from the ground with-

out damage. When you see sugar beets on the lifting rollers that are torn off at the bot-

tom, then the share depth must be lowered on the that row (deeper lifting).

If the soil is very loose and easily screened, lifting should be deeper than specifically

required. In this way, you achieve much more careful handling of the beets, because

then there is sufficient soil present for strainer wheel cleaning. This soil ensures a

damping effect and helps to avoid damage to the beets.

In case of very sticky soil, you should keep the lifting depth as small as possible. This

loads the cleaning installations substantially less with the soil present in abundance

anyway. In this case, if the lifting depth is too deep, this may result in an increased soil

content on the beets and to reduced throughput of the machine.

The lifting depth is set at different points:

– Setting rollers movement height

– Setting share depth, in some cases single rows are adjusted differently from the

general lifting depth (uneven ground etc.)

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...