Lists/Tables/Plans/Diagrams/Maintenance Verification

Lubricating and operating supplies

529 / 564

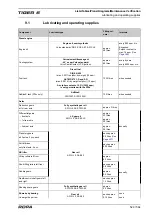

9.1

Lubricating and operating supplies

Component

Lubricant type

Filling vol-

ume:

Intervals

Diesel engine

Engine oil

Engine oil, semi-synthetic

Volvo standard VDS-3, ECEA E7, API CI-4

approx.

48 litres

every 500 oper. hrs.

Exception:

Sulphur content is

max. 15 ppm (

Cooling system

Corrosion/antifreeze agent

-40° as per Volvo standard:

Volvo Penta Coolant VCS (yellow)

approx.

60 litres

every 4 years,

every 8000 oper. hrs.

Fuel tank

Diesel fuel

DIN EN 590

(max. 0.001% sulphur by weight) (10 ppm)

ASTM D975 1-D and 2-D

(max. 0.0015% by weight sulphur) (15 ppm)

A sulphur content of 0.3% (3000 ppm)

is only permitted with the RT6a

1320 litres

when needed

AdBlue® tank (RT6c only)

AdBlue®

DIN 70070 / ISO 22241

130 litres

when needed

Axles

Reduction gears

at 1st rear axle

Fully synthetic gear oil

API GL5, SAE 75W-90

approx. 3 litres

Differential gears

→

front axle

→

1st rear axle

LS gear oil

API GL 5, SAE 90, LS

approx.

23 litres

approx.

30 litres

→

2nd rear axle

approx.

30 litres

Planetary gears

all 3 axles, 2 pcs. each

each approx.

9.2 litres (

)

Portal drives

only front axle, 2 pcs.

each approx.

8.25 litres

annually

RR lifter

Lifting rollers left front

approx.

6.2 litres

Short lifting rollers left front

each approx.

0.8 litres

Paddle gears

approx.

0.5 litres

Depth-control shaft gears left

and right

Gear oil

API GL 5, SAE 90

each approx.

1.0 litres

Shaking share gears

Fully synthetic gear oil

API GL5, SAE 75W-90

approx.

0.5 litres

annually

Share body bearing

Linear guide per row

Gear oil

API GL 5, SAE 90

each approx.

0.15 litres

none

none

Summary of Contents for Tiger 6

Page 3: ...Contents 3 564 Contents...

Page 4: ...Contents 4 564...

Page 13: ...Preface 13 564 1 Preface...

Page 14: ...Preface 14 564...

Page 22: ...Safety 22 564...

Page 23: ...Safety 23 564 2 Safety...

Page 24: ...Safety 24 564...

Page 41: ...General View and Specifications 41 564 3 General View and Specifications...

Page 42: ...General View and Specifications 42 564...

Page 53: ...General Description 53 564 4 General Description...

Page 54: ...General Description 54 564...

Page 57: ...Operating Components 57 564 5 Operating Components...

Page 58: ...Operating Components 58 564...

Page 98: ...Operation 98 564...

Page 99: ...Operation 99 564 6 Operation...

Page 100: ...Operation 100 564...

Page 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Page 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Page 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Page 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Page 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Page 362: ...Maintenance and Service 362 564...

Page 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Page 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Page 476: ...Malfunction and Remedies 476 564...

Page 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Page 558: ...558 564...

Page 559: ...Index 559 564 10 Index...

Page 560: ...Index 560 564...