5-46

5-23 Adaptive Filter

Ope

rati

n

g Func

tions

5

The adaptive filter may not function properly under the following

conditions.

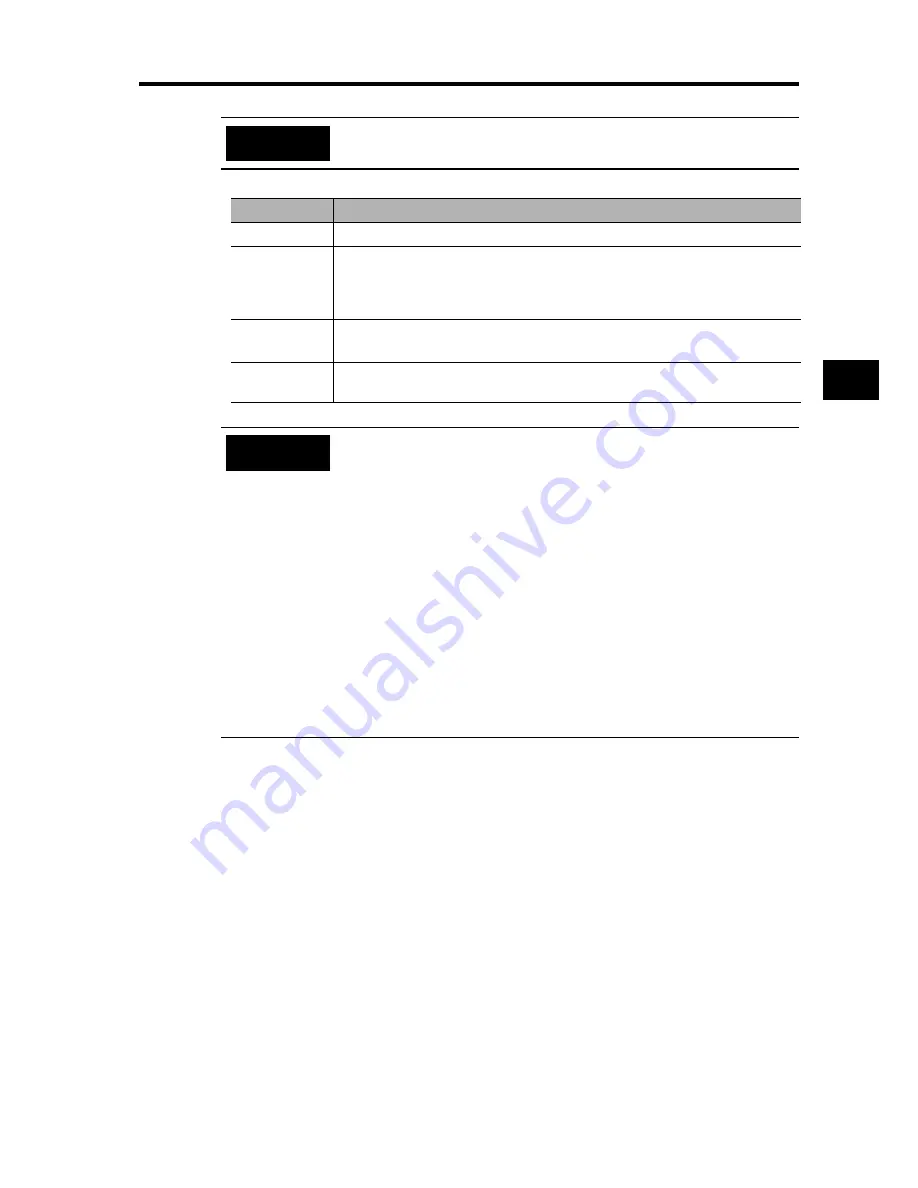

Conditions under which the adaptive filter does not function properly

Control Mode

In Torque Control Mode. (Operates in position and speed control modes)

Resonating load

status

If the resonance frequency is 300 Hz or lower.

If there are multiple points of resonance.

If the resonance peak or control gain is low, and the Servomotor speed is not

affected by it.

Load status

If the Servomotor speed with high-frequency components changes due to

backlash or other non-linear elements (play).

Command

pattern

If the acceleration/deceleration suddenly changes, i.e. 3,000 r/min or more in

0.1 s.

Unusual noise or vibration may occur until the adaptive filter stabilizes after

startup, immediately after the first servo ON, or when the Realtime

Autotuning Machine Rigidity Selection (Pn022) is increased, but this is not

a problem if it disappears right away. If the unusual noise or vibration,

however, continues for three or more reciprocating operations, take the

following measures in any order you can.

Write the parameters used during normal operation to the EEPROM.

Lower the Realtime Autotuning Machine Rigidity Selection (Pn022).

Disable the adaptive filter by setting the Adaptive Filter Selection (Pn023)

to 0. (Reset the inertia estimate and adaptive operation)

Set the notch filter manually.

Once unusual noise or vibration occurs, the Inertia Ratio (Pn020) may

have changed to an extreme value. In this case, also take the measures

described above.

The Adaptive Filter Table Number Display (Pn02F) is written to the

EEPROM every 30 minutes, and when the power supply is turned OFF

and turned ON again, this data is used as the initial values for the adaptive

operation.

Precautions

for Correct Use

Precautions

for Correct Use