7.2Troubleshooting

7-10

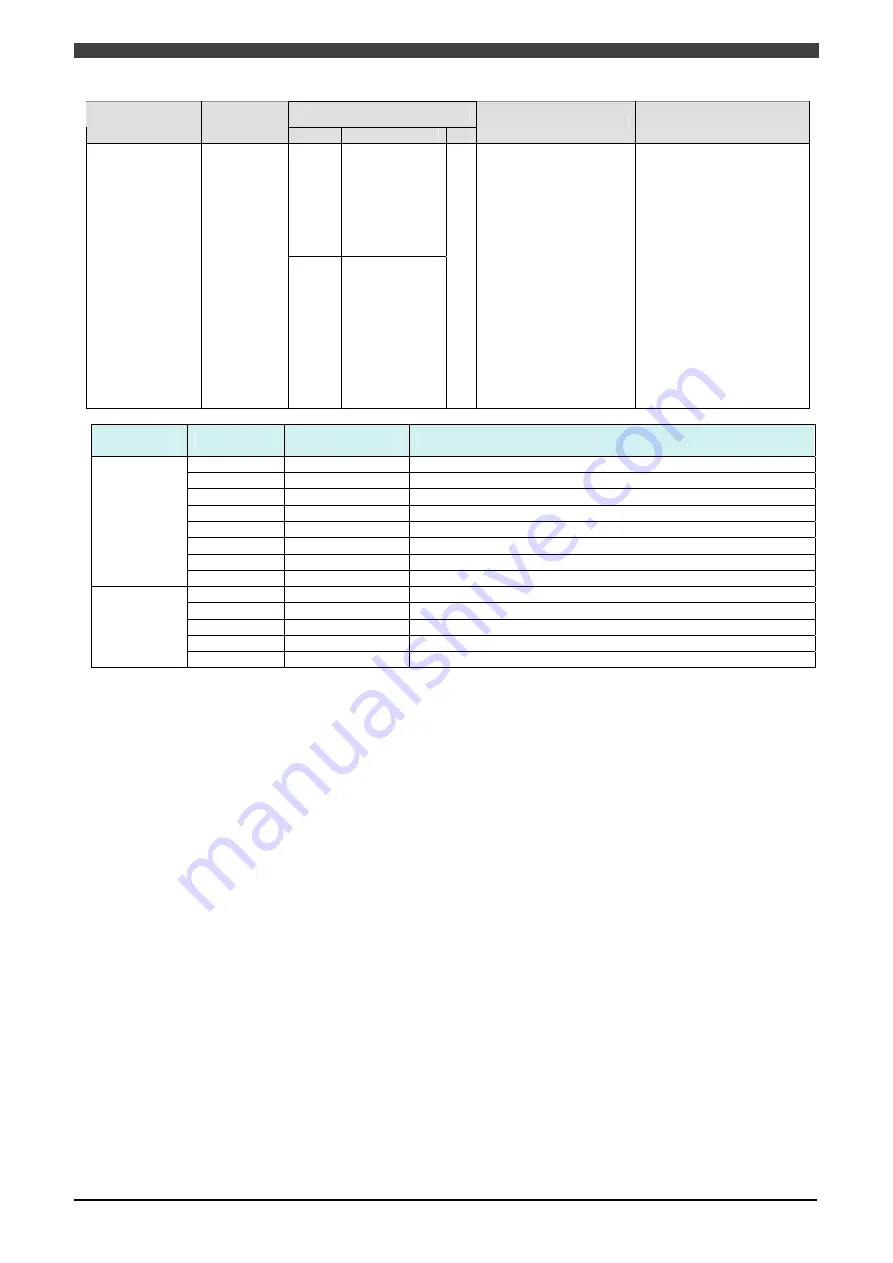

Assist code

Error

Error code

Top: Controller

Bottom: RMU

1

2

3

Description of trouble

Remedy

16

1 Safety input 1

2 Safety input 2

4 Safety input 3

8 Safety input 4

16 Safety input 5

32 Safety input 6

64 Safety input 7

128 Safety input 8

Disparity error

of input signal

E1105

E07

48

1 Safety input 9

2 Safety input 10

4 Safety input 11

8 Safety input 12

16 Safety input 13

-

This error occurs when

the redundant safety

signals which are input

to the RMU have been

detected as different

logic.

If a robot emergency

stop disparity has been

detected, the

emergency stop output

is turned OFF. When

any other disparity has

been detected, the

power supply output is

turned OFF.

After removing the cause

of the error, turn OFF both

of those redundunt

signals, and then press

[Reset] key twice.

Please refer to “2.3.2

safety inputs” table 2-10

for the detail of safety

input signals.

Assist code

SUB1

Assist code

SUB2

Assist code

SUB3

Description

1

Safety input 1

"Robot emergency stop signal" is inconsistent.

2

Safety input 2

"Enable switch signal" is inconsistent.

4

Safety input 3

"Slave error signal" is inconsistent.

8

Safety input 4

"Robot LS detection signal" is inconsistent.

16

Safety input 5

"Emergency stop signal" is inconsistent.

32

Safety input 6

"Safety plug signal" is inconsistent.

64

Safety input 7

"Protective stop signal" is inconsistent.

16

128

Safety input 8

"External enable signal" is inconsistent.

1

Safety input 9

"General input 1 signal" is inconsistent.

2

Safety input 10

"General input 2 signal" is inconsistent.

4

Safety input 11

"General input 3 signal" is inconsistent.

8

Safety input 12

"General input 4 signal" is inconsistent.

32

16

Safety input 13

"General input 5 signal" is inconsistent.

(NOTE) When plural errors happen at the same time in ASSIST CODE SUB1, the ASSIST CODE SUB 2 value will become

the total number of each value.

Summary of Contents for RMU20-20

Page 2: ......

Page 6: ...Contents 4 ...

Page 8: ......

Page 26: ...1 4 EC DECLARATION OF CONFORMITY FOR MACHINERY 1 18 NOTE ...

Page 68: ...2 9 Enabling RMU 2 40 NOTE ...

Page 70: ......

Page 100: ...3 4 Setting when a slider unit is used 3 30 NOTE ...

Page 102: ......

Page 138: ...4 4Approval 4 36 8 Approval is completed The following screen will be displayed ...

Page 144: ......

Page 154: ...5 4Trouble shooting 5 10 NOTE ...

Page 156: ......

Page 166: ...6 4Trouble shooting 6 10 NOTE ...

Page 168: ......

Page 189: ......