1.1 Outline

1-6

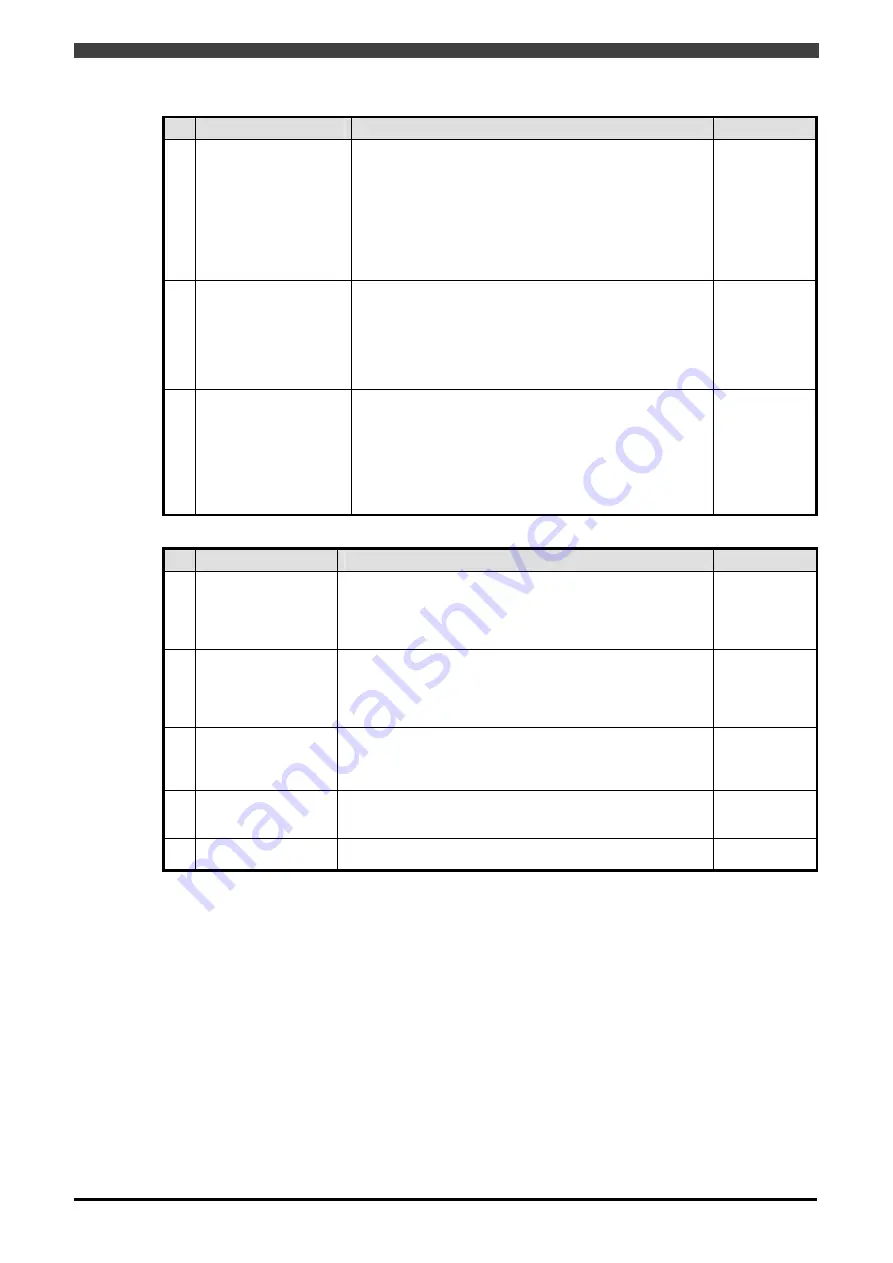

Encoder and motor interface

Item

Specifications

Remarks

1 Basic

functions

<Encoder>

It is possible send/receive data to/from the bidirectional

serial communication encoder.

It is possible to read communication between servo

amplifier and encoder together with request data and

encoder output data.

<Motor>

The motor position can be read out from the power line of

the motor.

2 Connection

method

<Encoder>

For the method of connecting encoder, 1-axis individual

connection or bus connection is available.

For both individual and bus connections, up to 8 axes can

be connected.

The connection method can be specified, using the

parameter of “Encoder type”.

3 Error

detection

<Encoder>

Encoder detection error

Timeout detection (hardware)

Encoder ID check (hardware)

Line disconnection detection (software)

<Motor>

Motor magnetic pole position is compared with the

encoder, and detects the mismatch of their angle.

Input/output signal, Motor power control sequence processing

Item

Specifications

Remarks

1 Safety

inputs

This is to read the safety signal.

For further details, see “2.3.2 Safety inputs.”

Diagnoses system short circuit between inputs, input circuit

failure, disparity between two inputs, and over current.

If an error is detected, safety output is turned OFF.

2 Safety

outputs

This is to output the safety signal.

For further details, see “2.3.3 Safety outputs.”

Diagnoses system short-circuit between outputs, output

circuit failure, and back check input circuit failure.

If an error is detected, safety output is turned OFF.

3 Monitor

inputs

This is to the read non-safety signal.

For further details, see “2.3.5 Non-safety inputs.”

Diagnoses input circuit failure and over current.

If an error is detected, safety output is turned OFF.

4 Monitor

outputs

This is to the output non-safety signal.

For further details, see “2.3.6 Non-safety outputs.”

If an error is detected, safety output is turned OFF.

5

Motor power control

sequence

This is to set the safety output to ON/OFF depending on

input conditions such as emergency stop and enable switch.

Summary of Contents for RMU20-20

Page 2: ......

Page 6: ...Contents 4 ...

Page 8: ......

Page 26: ...1 4 EC DECLARATION OF CONFORMITY FOR MACHINERY 1 18 NOTE ...

Page 68: ...2 9 Enabling RMU 2 40 NOTE ...

Page 70: ......

Page 100: ...3 4 Setting when a slider unit is used 3 30 NOTE ...

Page 102: ......

Page 138: ...4 4Approval 4 36 8 Approval is completed The following screen will be displayed ...

Page 144: ......

Page 154: ...5 4Trouble shooting 5 10 NOTE ...

Page 156: ......

Page 166: ...6 4Trouble shooting 6 10 NOTE ...

Page 168: ......

Page 189: ......