[

V

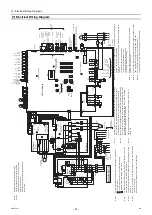

Electrical Wiring Diagram ]

- 53 -

HWE15070

GB

V

Electrical Wiring Diagram

[1] Electrical Wiring Diagram

5

4

6

2 1

3

5 4

6

3

1

2

34

L3

L3

L2

L2

L1

L1

N

N

5

61

32

42

22

12

3

13

26

46

4

55

4

3

3

2

2

1

1

1

1

13

11

1

23

2

24

22

2

12

3

11

1

66

6

77

7

55

5

44

4

33

3

22

2

2

2

2

2

1

1

1

1

1

11

3

33

4

2 1

3

4

1

1

1

1

2

2

2

3

3

3

3456

1

1

1

2

2

2

2

2

3

7

6

5

4

1

2

2

1

1

4

4

4

4

2

2

2

2

5

5

5

4

4

4

3

3

3

2

2

2

2

1

1

1

3

1

1

1

1

3

3

4

1

6

6

6

7

7

3

2

2

2

2

1

1

1

1

3

3

3

3

2

2

1

1

3

3

2 1

3

LED4: Power supply

SW421

2

1

ON

OFF

Flow switch

Mode change 1

Capacity mode

Demand

Anti freeze

23

24

T3

T4

TH15

CN406 yellow

(Hot water/

Heating)

(Normal/Error)

(ON/OFF)

(ON/OFF)

(ON/OFF)

(ON/OFF)

(COP

priority/

Capacity

priority)

Pump

interlock

(Normal/Error)

Fan mode

(coercion/

by ordinary)

Run

Run/Stop

Mode

change 2

(Heating Eco/

Heating)

No-V

oltage

contact

input

SW01

SW02

SW03

ON

OFF

ON

OFF

ON

OFF

CN332

blue

MAIN BOX

LED1

Control Board

LED3: Remote controller

lit while energized

LED2: CPU in operation

Unit address setting

(0)

10'

digit

SWU1

(1)

1'

digit

(0)

SWU2

SWU3

2

1

1

2

3

4

5

6

7

8

9

10

1

2

10

10

9

8

7

6

5

4

3

3

4

5

6

7

8

9

ENTER

SWP2

SWP3

UP

SWP1

DOWN

B

A

OFF

LOCAL

SWS1

SWS2

REMOTE

63H1

X07

X06

X05

X09

X04

X08

X01

X02

X03

CN502

CN501

CH

SV1

SV2

21S4

72C

CNAC

red

black

CNAC2

CN421 black

DC12V

No-voltage contact output

Pump operation

command output

Emergency

signal A

(for extra

heater)

*11

Drain pan

heater/

Defrost signal

Error display output

Operation display

output

pump error

T1

(+)

(–

)

T2

12

11

20

19

16

RB

MB

B

MA

A

RA

15

74

75

71

70

72

66

62

73

63LS

63HS

TH9

TH4

TH1

TH14

TH16

TH1

1

CN408

TH2

M

TH3

LEV1

52P

51P

CNL

VC

blue

M

LEV2

CNL

V

A

CN407 red

CN3A

blue

blue

CN51

1

yellow

CN512

CN4

CN2

Contorol

power circuit

CN510

CN142A

black

Outdoor temp. 1

Air hex Ref

temp. 1

*12, *13

Wa

ter temp. setting

Analog input

4~20mA/0~10V

1~5V/2~10V

Capacity

control signal

Discharge Ref

temp. 1

Suction Ref

temp. 1

Wa

ter inlet

temp. 1

External

Wa

ter sensor. 1

External

Wa

ter sensor. 2

Wa

ter outlet

temp. 1

Shell Ref temp. 1

Optional remote controller

connecting terminal

(Non-polarized)

T

ransmission cable for multiple unit control

Measurement terminal for maintenance (M-NET)

T

O

SUB BOX

TB3

T

o

SUB BOX

TB4

F06 AC250V 3.15A

T

F2

L1

L2

L3

N

CN63LS red

CN405 blue

CN402 green

CN404 black

CN401

CN142B

blue

CN142C

CN142D

blue

CN801

yellow

CN102

Z21

52P

PL

M

3~

MP

CN63HS

TB2

ELB1

ELB2

TB1

L1

L2

L3

N

CNTYP1 black

power supply

3N~

50Hz

380/400/415V

power supply

3N~

50Hz

380/400/415V

C5

Z5

C3

C2

F02

R01

R02

F01

R03

Z1

Z2

R34

C30

C32

C34

C36

black

F03

F04 AC250V 6.3A

T

black

white

L

F01,F02,F03 AC250V 6.3A

T

DSA

R35

CT3

white

R33

SC-L3

R30

red

red

white

white

D1

R04

R32

R06

CN2

C31

CN18V blue

U

Z4

C17

CN4 red

TB21

CN1B

L1

CN1A

red

Noise

Filter

TB22

CN3 green

TB24

Fan motor

(Heat exchanger)

W

a

ter side

Heat exchanger

N

C33

TB23

IPM

F

A

N Board

F05 AC/DC400V 10A

T

*2

M

3~

MS

3~

black

U

red

Diode

Bridge

2

72C

1

black

SC-P2

C7

C8

CT12

L2

R5

U

LED1: Normal

operation

+

red

C35

DCL

SC-L2

SC-P1

SC-U

CN1

black

black

C37

CN5V yellow

C1

C9

C10

CN6

4

C100

LED1: Normal operation (lit)

/ Error (blink)

Motor

(Compressor)

LED3: CPU in

operation

R1

CN4

CN2

SC-V

U

IGBT

CT22

U

CNINV

SC-W

SC-L1

W

CN21 blue

U

U

V

W

CNVDC

CN4 blue

C631

t°

LED2: Error

R630

R631

CN22 red

Z3

CN5

R31

C6

CNTYP

black

CNTYP2

CN52C red

TB5

TB5

TB6

TB6

TB6

TB6

TB5

TB6

TB6

CNDC Pink

C1

RSH1

THHS

FT

-P

P

N

FT

-N

C4

+

INV Board

+

C630

+

+

+

+

+

+

3

red

L3

THBOX

–

+

V

t°

t°

t°

t°

t°

t°

t°

t°

t°

t°

black

5 4

3

1

2

CN105

IT

TERMINAL

Note

3.

The symbols

used for dif

fere

nt types of term

inals are as follows

:

: T

erminal blo

c

k

: Cut the sho

rt-circuit wire, and co

nnect field wiring

: Bullet termina

l (field supply: male

ø3.96)

Note

4.

T

o

switch be

tween "Ca

p

acity prio

rity" and "

COP priority

,"

remove the

short-circuit wire

on terminal 23 a

nd CN142-6.

Note

5.

The broke

n

lines indicate th

e optional p

a

rt

s, field-supplied p

a

rt

s, and

field work.

Note

6.

Be sure to

connect the w

ire

s from terminals 1

1

and 12 to th

e interlock

cont

act on the p

ump.

A short-circuit

may cause abn

ormal stop or malfu

nctions.

Note

7.

Operation signa

ls can be re

ceived from th

e remote cont

roller or through

the dry cont

act. The tem

perature setting

can be chang

ed by a signal

received through

the dry cont

act or by u

sing the schedu

le setting.

Note 8.

Leave a sp

ace of at le

ast 5 cm betwee

n the low volt

age extern

al wiring

(no-volt

a

g

e

cont

act inpu

t and

re

mote contro

ller wiring) a

nd wiring

of 100

V or greater

. Do

not place them

in the same con

duit tube or cab

tyre

cable as this will da

mage the circuit

board.

Note 9.

The volt

a

ge/current app

lied to the dry co

nt

act sh

ould not excee

d

12

VDC/5 mA.

No

te 10.

When

cabtyre cable is u

sed for the con

trol cable wiring, u

se a sep

arate

cabtyre

cable for the f

ollowing wiring.

Using t

he same cabtyre

cable may cause

malfunctions an

d damage to

the u

nit.

(a)

Option

al remote controlle

r wiring

(b)

No-volt

age con

tact inpu

t wiring

(c)

No-volt

age con

tact out

put wiring

(d)

Remote

water temp. sett

ing

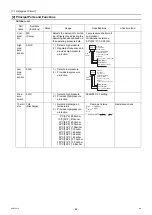

No

te 1

1

.

Select

s

either D

rain p

a

n

signal or Defrost s

ignal by SW2 an

d SW3

setting

s. (Item code 10

56)

No

te

12.

Select

s

either W

ater tempe

rature setting input signa

l

or Cap

acity control

input

signal by SW2 an

d SW3 settings.

(Item code 1051

)

No

te 13.

Use a

4-20 mA signal ou

tput device with

insulation.

Feedin

g

30 mA or more

current may dama

ge the circuit bo

ard.

Not

e1.

S

ingl

e-dot

te

d line

s

ind

ica

te

f

ield

wiri

ng.

Note2.

Fa

ston

termina

ls ha

ve

a

locking

function.

Check that

the

termin

a

ls a

re

securely

locked

in place af

ter

in

se

rtio

n.

Pre

ss

the t

a

b

in th

e

mid

d

le of th

e

termin

a

ls

to

remove them.

0000001906.book 53 ページ 2015年11月5日 木曜日 午前11時55分

Summary of Contents for CAHV-P500YB-HPB

Page 1: ......

Page 7: ...CONTENTS HWE15070 GB ...

Page 9: ... 2 HWE15070 GB ...

Page 19: ... 12 HWE15070 GB ...

Page 37: ... 30 II Restrictions GB HWE15070 ...

Page 39: ... 32 HWE15070 GB ...

Page 48: ... 41 HWE15070 GB IV Remote Controller 1 Using the Remote Controller 43 2 Function Settings 48 ...

Page 49: ... 42 HWE15070 GB ...

Page 57: ... IV Remote Controller 50 HWE15070 GB ...

Page 58: ... 51 HWE15070 GB V Electrical Wiring Diagram 1 Electrical Wiring Diagram 53 ...

Page 59: ... 52 HWE15070 GB ...

Page 65: ... 58 V Electrical Wiring Diagram GB HWE15070 ...

Page 67: ... 60 HWE15070 GB ...

Page 71: ... VI Refrigerant Circuit 64 HWE15070 GB ...

Page 73: ... 66 HWE15070 GB ...

Page 111: ... 104 HWE15070 GB ...

Page 117: ... VIII Test Run Mode 110 HWE15070 GB ...

Page 119: ... 112 HWE15070 GB ...

Page 163: ... IX Troubleshooting 156 HWE15070 GB ...

Page 164: ... 157 HWE15070 GB X Attachments 1 R407C saturation temperature table 159 ...

Page 165: ... 158 HWE15070 GB ...

Page 167: ... X Attachments 160 HWE15070 GB ...

Page 168: ......