Rev. 1.01 Technical changes reserved.

© Janich & Klass Computertechnik GmbH, Wuppertal, 2015

page 6-73

XINO

®

S700

Operation

Chapter

6

6.4.6.1

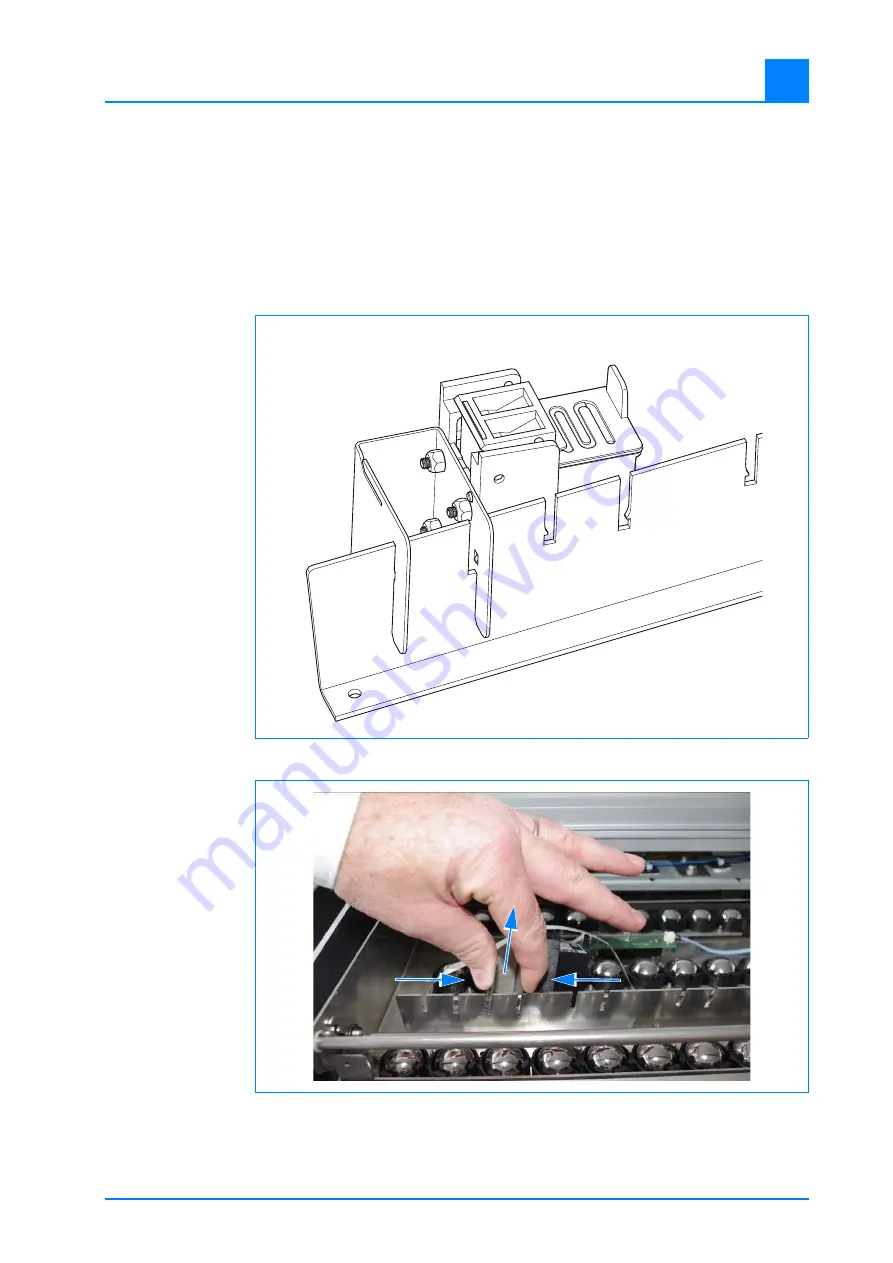

Changing the print position

For different print positions the print head can be placed at 5 different positions. In

order to change the position of the print head, please proceed as follows:

1.

Press the two rear plates of the clip together.

2.

Remove the print head holder by pulling it diagonally upwards.

3.

Insert the clip at the new print position.

4.

Press the clip down until it clicks into place on both sides.

Fig. 6-71

Print head clip mechanism

Fig. 6-72

Removing the print head