King Edge Vac

Operating Guidelines

3-9

Flatwork Handling

The way that operators use the feeder is very

important. They can increase productivity, extend

the life of the unit, and most importantly, promote

safety.

Safety

Always follow the site standards to

avoid repetitive motion injury.

If an item jams, do not reach inside the

unit while the power is on. Refer to

Handling a Jam Safely

.

If an item falls, leave it until the end of

the batch. Refer to

Handling Misfeeds

Safely

.

Program Selection

Pressing a STATION key will select a preset

program by number and item type. The presets

are for KING Sheet’s, COTTON and 75/25, and

QUEEN Sheet’s, COTTON and 75/25.

Pressing a STATION key until the light goes

off leaves the feeder running in stand-by mode.

Set Pacing (Option)

If the unit is equipped with the optional pacing

lights, follow theses steps to set the unit to signal

whether the pace is being met on a hourly basis.

On the CHI Panel, press and hold the AD-

JUST button; then, press the ENTER but-

ton. Release both buttons. The SELECT

ADJUSTMENT menu displays:

SELECT ADJUSTMENT

INL TRN SPR FEED IRN CHI

The flashing cursor is under CHI.

Press the ENTER button. The Program

Adjustments (CHI) menu displays:

FAST=10” LSP290 TORQ.08S

AIR.16S GAP-07” PACE=420

•

•

•

1.

2.

Press the CURSOR button until it is under

the pace setting.

Press the + or - key as appropriate to set

the desired hourly standard. The range is

from 240 to 660 pieces per hour, in 20

piece increments.

When the correct value is displayed, press

ENTER.

The SELECT ADJUSTMENT menus

displays. Press ENTER again to return to

normal operation.

Feeding Sheets (large pieces)

NOTE:

The unit is designed to

process large pieces of flatwork

ranging in size from 48” (1220

mm) to 120” (3050 mm). It is NOT

designed to feed folded flatwork.

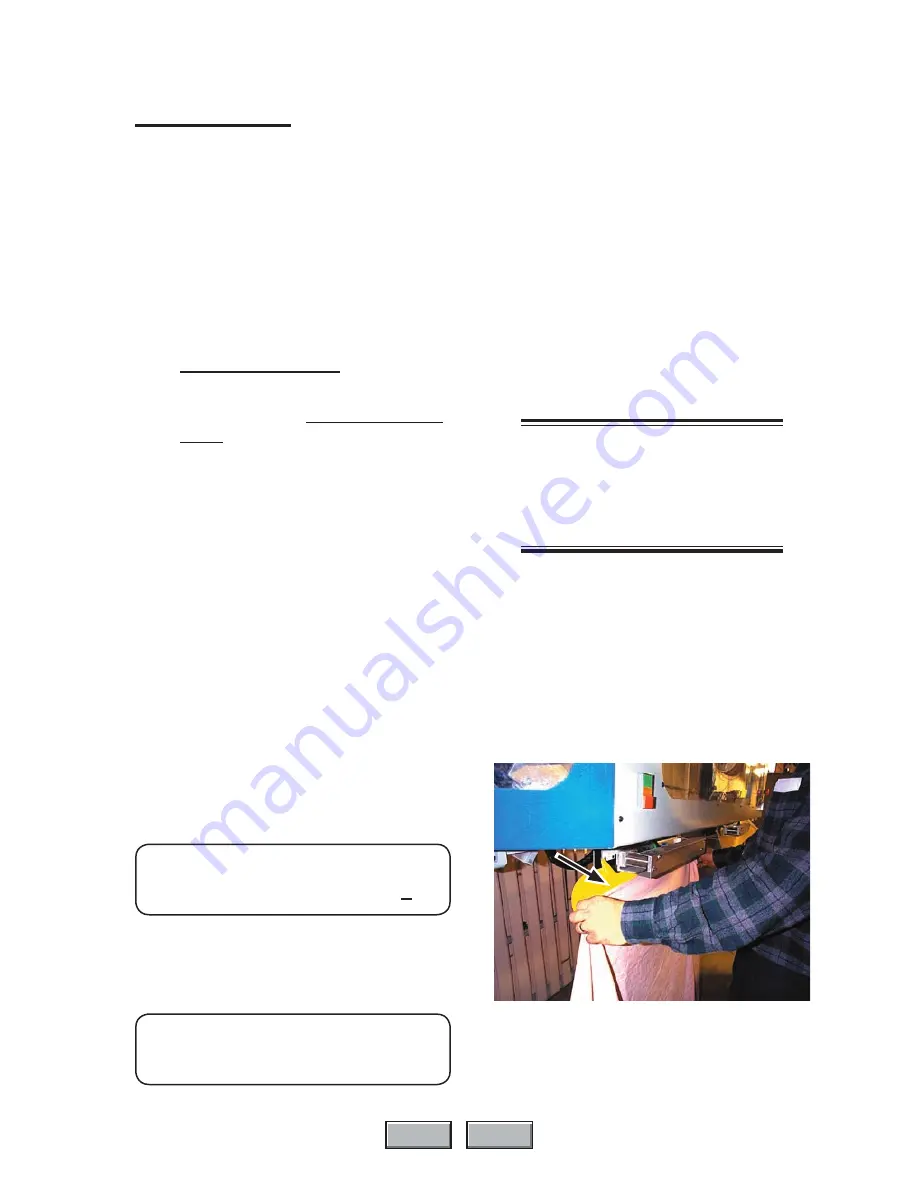

Remove a sheet from the laundry basket.

Place the approximate center of the long

edge of the sheet up along the yellow

station table guide between the carriage

clamps (Figure 3-9).

3.

4.

5.

6.

1.

2.

Figure 3-9: Place the approximate center of the

long edge of the sheet up along the

yellow guide into the feed conveyor

clamps.

TOC

INDEX

Summary of Contents for King Edge VAc

Page 12: ......

Page 40: ......

Page 54: ......

Page 78: ......

Page 250: ...3038 015e King Edge VAC PL 32 This page intentionally left blank TOC INDEX PL TOC...

Page 262: ...SC 2 460V Motor Circuit SC TOC TOC INDEX...

Page 264: ...SC 4 208 230V Motor Circuit SC TOC TOC INDEX...

Page 266: ...SC 6 Control Power Communications SC TOC TOC INDEX...

Page 268: ...SC 8 Controller Inputs SC TOC TOC INDEX...

Page 270: ...SC 10 Control Outputs SC TOC TOC INDEX...

Page 273: ...King Edge Vac 3210 437b SC 13 This page intentionally left blank SC TOC TOC INDEX...

Page 274: ...SC 14 Prefeeder Control Circuit SC TOC TOC INDEX...

Page 276: ...3210 437b King Edge Vac SC 16 This page intentionally left blank SC TOC TOC INDEX...

Page 277: ...SC 17 24 VAC Control Circuit SC TOC TOC INDEX...

Page 278: ...SC 18 Interlock Circuit system E stop SC TOC TOC INDEX...

Page 279: ...SC 19 Pneumatic Diagram SC TOC TOC INDEX...

Page 280: ...SC 20 Prefeeder Electrical Panel SC TOC TOC INDEX...

Page 282: ...SC 22 Disconnect Panel SC TOC TOC INDEX...

Page 284: ...SC 24 Main Eletrical Panel SC TOC TOC INDEX...

Page 285: ......

Page 286: ......

Page 287: ......

Page 288: ......

Page 290: ......

Page 292: ......

Page 302: ......