Chapter 6

6-8

The transfer unit consists of a transfer roller [1] and an static eliminator [2].

The transfer roller is driven by the photosensitive drum.

The static eliminator is biased to separate paper from the drum.

F-6-12

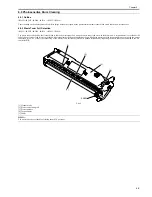

6.8.2 Controlling the Transfer Bias

6.8.2.1 Transfer Roller Bias Control

0017-4356

iR2022i / iR2025 / iR2030 / iR2018 / iR2022 / iR2018i

A negative bias, sheet-to-sheet bias, or positive bias is applied to the transfer charging roller according to the type of sequence.

The negative bias is applied at the prescribed timing to moves the toner from the transfer charging roller to the photosensitive drum for cleaning.

The sheet-to-sheet bias is lower than that applied during printing and it is applied at the prescribed timing to prevent the toner remaining on the photosensitive drum

from adhering to the transfer charging roller.

The positive bias is applied to transfer toner images from the photosensitive drum to paper.

F-6-13

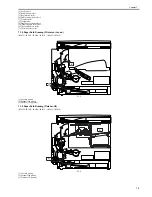

6.8.3 Separation Mechanism

6.8.3.1 Static Eliminator Bias Control

0017-4357

iR2022i / iR2025 / iR2030 / iR2018 / iR2022 / iR2018i

Two types of biases, a high-output bias and a low-output bias, are applied to the static eliminator using the static eliminator bias drive signal (/DISDCFOT) and

static eliminator bias output level signal (/DSCPWM) issued from the DC controller PCB according to the type of the print sequence, thus allowing the printing

paper to separate easily from the photosensitive drum.

F-6-14

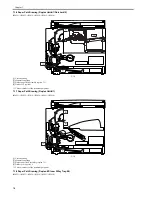

[1]

[2]

Tr3

TRCRNT

/TRPWM

To transfer

charging roller

Transfer bias circuit

ASIC

CPU

Positive current

detection circuit

Positive voltage

generation circuit

Negative voltage

generation circuit

Comparison

circuit

/TRPFOT

TRCHG

/TRNFOT

Superimposition

Constant current/voltage

switching circuit

High-voltage power supply PCB

DC

controller

PCB

/DSCPWM

/DISDCFOT

To static eliminator

Static eliminator bias circuit

ASIC

CPU

Static eliminator bias

generation circuit

High-voltage power supply PCB

DC controller

PCB

JP9/JP10

Summary of Contents for imageRunner 2022

Page 1: ...Aug 8 2007 Service Manual iR2030 2025 2022 2018 Series ...

Page 2: ......

Page 6: ......

Page 20: ...Contents ...

Page 21: ...Chapter 1 Introduction ...

Page 22: ......

Page 57: ...Chapter 1 1 33 ...

Page 60: ......

Page 61: ...T 1 11 ...

Page 64: ......

Page 65: ...T 1 12 ...

Page 68: ......

Page 69: ...Chapter 2 Installation ...

Page 70: ......

Page 72: ......

Page 125: ...Chapter 2 2 53 ...

Page 126: ......

Page 127: ...Chapter 3 Main Controller ...

Page 128: ......

Page 130: ......

Page 142: ......

Page 143: ...Chapter 4 Original Exposure System ...

Page 144: ......

Page 170: ......

Page 171: ...Chapter 5 Laser Exposure ...

Page 172: ......

Page 174: ......

Page 181: ...Chapter 6 Image Formation ...

Page 182: ......

Page 184: ......

Page 196: ......

Page 197: ...Chapter 7 Pickup Feeding System ...

Page 198: ......

Page 217: ...Chapter 8 Fixing System ...

Page 218: ......

Page 220: ......

Page 234: ......

Page 235: ...Chapter 9 External and Controls ...

Page 236: ......

Page 255: ...Chapter 10 RDS ...

Page 256: ......

Page 258: ......

Page 268: ......

Page 269: ...Chapter 11 Maintenance and Inspection ...

Page 270: ......

Page 272: ......

Page 275: ...Chapter 12 Standards and Adjustments ...

Page 276: ......

Page 278: ......

Page 281: ...Chapter 12 12 3 ...

Page 282: ......

Page 283: ...Chapter 13 Correcting Faulty Images ...

Page 284: ......

Page 286: ......

Page 299: ...F 13 11 F 13 12 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 ...

Page 300: ......

Page 301: ...Chapter 14 Self Diagnosis ...

Page 302: ......

Page 304: ......

Page 317: ...Chapter 15 Service Mode ...

Page 318: ......

Page 381: ...Chapter 16 Upgrading ...

Page 382: ......

Page 384: ......

Page 411: ...Chapter 17 Service Tools ...

Page 412: ......

Page 414: ......

Page 417: ...Aug 8 2007 ...

Page 418: ......