299

Trim and Tilt

Troubleshooting

13

again, and add fluid if necessary. Remember that

all rods must be completely extended to check

fluid level.

Starting with the tilt cylinder fully retracted, run the

unit UP.

•

The gauge should show 0 to 200 psi (0 to 1379

kPa) as the tilt cylinder is extending.

•

The gauge should show 1400 to 1600 psi (9653

to 11032 kPa) as the unit stalls.

•

Release the switch and watch for a pressure

drop. The stall pressure reading must not drop

more than 200 psi (1379 kPa) after motor stops.

If results vary from the above limits, there is a

problem in the UP circuit. Refer to

on p. 290 for circuit description.

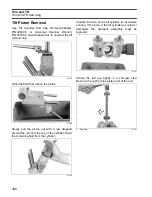

STEP 2

Remove the manual release valve retaining ring

using retaining ring pliers.

Remove the manual release valve. Install pres-

sure gauge and adapter “B” to check problems in

the DOWN circuit. Cycle the unit down and up

several times to purge air. With all rods fully

extended, run the unit down momentarily to

reduce pressure. Check fluid level again, and add

fluid if necessary. Remember that all rods must be

completely extended to check fluid level.

Starting with the tilt cylinder fully extended, run the

unit DOWN.

•

The gauge should show 0 to 200 psi (0 to 1379

kPa) as the tilt cylinder is retracting.

•

The gauge should show approximately 800 psi

(5516 kPa) as the unit stalls.

•

Release the switch and watch for a pressure

drop. The stall pressure reading must not drop

more than 200 psi (1379 kPa) after motor stops.

If results vary from the above limits, there is a

problem in the DOWN circuit. Refer to

on p. 290 for circuit description.

Check fluid level again and add fluid, if necessary.

41757

41754

CAUTION

After tests are complete, run the unit up, then

down momentarily. Cycle the unit down and

up several times to purge air. With all rods

fully extended, run the unit down momentar-

ily to reduce pressure.

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...