65

Engine Management Module (EMM)

Engine Monitor System

4

Engine Monitor

System

All remote controlled outboards, 40 HP and

above, must be equipped with an engine monitor-

ing system to warn the operator of conditions that

could damage the outboard.

The engine monitor system includes sensors on

the outboard and oil tank, a warning horn, a

dash-mounted display, and related wiring.

The outboard’s

EMM

sends information about

monitored functions to:

•

SystemCheck

gauges

•

An

I-Command

or

ICON

display

•

EMM

LED indicators.

IMPORTANT:

Operating the outboard without an

engine monitor will void the warranty for failures re-

lated to monitored functions. For information about

boat mounted Information Display System options,

refer to the current

Predelivery and Installation

Guide

included with the service manual set.

The

EMM

activates the warning horn and gauge

displays as follows:

•

LOW OIL means that oil in the tank is at reserve

level (about 1/4 full).

•

NO OIL indicates the oil tank is empty, or the oil

system is damaged.

•

WATER TEMP or HOT indicates an engine or

EMM

overheat condition.

•

CHECK ENGINE or FAULT is used to indicate

other fault conditions identified by the

EMM

.

Refer to the

EMM

Service Code Chart

at the

back of this manual for a complete list of all fault

codes.

System Self-Test

During engine start-up, pause with the key switch

in the ON

position. The horn self-tests by sound-

ing a half-second beep.

SystemCheck

gauges

self-test by turning the indicator lights on simulta-

neously, then off in sequence.

Note:

The warning horn does NOT sound in an

I-Command

installation.

Service Mode

SystemCheck

goes into a service mode if the key

is left ON after self-test (engine NOT

running). All

light circuits and sensors are active, but the horn

is not. Grounding the appropriate light circuit wire

will turn the light on, but the horn will not sound.

Refer to

Engine Running

All warning circuits are active when the engine is

running. The horn circuit is active when engine

speed exceeds 500 RPM.

Engine monitor warnings activate the horn for 10

seconds and the appropriate gauge light for a

minimum of 30 seconds. If the failure is momen-

tary (for example, oil moving in the tank), the light

will remain ON for the full 30 seconds before

going out. If the fault continues, the light remains

ON until the key is turned OFF or the failure is cor-

rected. The warning will reoccur at the next

start-up if the problem is not corrected.

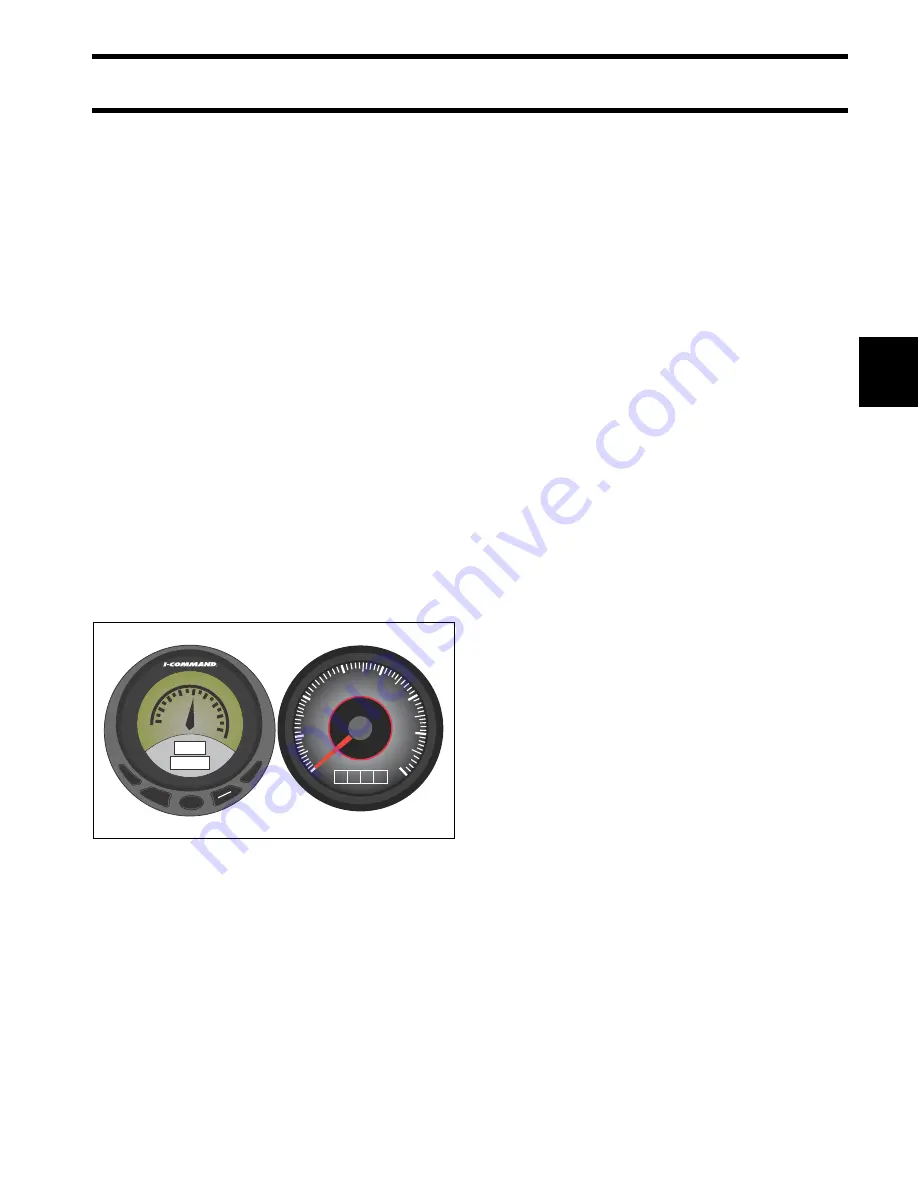

Typical

I-Command

and

SystemCheck

gauges

007988

1

0

2

3 4

5

6

7

r /mi n

x 1O O O

CHK

ENG

NO

OIL

LOW

OIL

HOT

M E N U

DOWN

UP

EXIT

PAGES

ENTER

30

20

10

0

40

50

60

70

x 100

RPM

3550

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...