195

Cooling System

Engine Temperature Check

9

adapter. The water reduces inner exhaust tem-

peratures and cools the propeller hub.

On 3.4 L models, propeller hub cooling water

flows through an internal passage of the inner

exhaust housing.

EMM

and Vapor Separator

Cooling

Cooling water is routed from the top of the cylinder

block to the inlet fitting of the

EMM

water cavity.

Cooling of the

EMM

helps to stabilize the tem-

peratures of internal components.

IMPORTANT:

Improper

EMM

cooling will acti-

vate service codes 25 and 29 and the Engine Mon-

itor warning system. Refer to the

EMM

Service

Code Chart

at the back of this manual for specific

service code information.

Cooling water from the

EMM

is routed to the water

inlet fitting of the vapor separator water cavity.

Cooling the vapor separator fuel chamber mini-

mizes fuel vaporization.

Cooling water from the vapor separator is routed

to the adapter/exhaust housing.

Engine Temperature

Check

IMPORTANT:

The engine temperatures listed

below are based on an intake water temperature of

70° ± 10°F (21° ± 3°C).

Install correct test propeller and place outboard in

a test tank or in the water. Start outboard and run

at 3000 RPM in FORWARD gear for at least five

minutes. Remember, running outboards at high

speeds in test tanks may disrupt water flow to

gearcase water intakes. Make sure the outboard

has adequate water flow.

Reduce speed to IDLE for five minutes. Check

IDLE operating temperature.

Increase speed to 5000 RPM and check tempera-

ture.

Check temperature on both sides of powerhead.

If engine temperature is not within range, trouble-

shoot cooling system.

If engine temperature tests within range, but the

engine monitor display indicates a “WATER

TEMP” warning, refer to

3.3 Liter Models

1.

External water supply hoses

2.

Exhaust (plenum)

3.

Inner exhaust cooling hose

000698r

2

1

1

3

CAUTION

When servicing the propeller, always shift the

outboard to NEUTRAL, turn the key switch

OFF, and disconnect the Crankshaft Position

Sensor (CPS) to prevent accidental engine

starting.

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

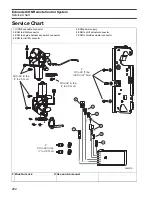

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...