Oiling System

Oiling System Tests

178

Oiling System Tests

IMPORTANT:

Always perform visual inspections

to identify oiling system leaks. Make sure the oil

tank is filled and oil supply is not contaminated.

Oil Injection Pump Static Test

The

EMM

controls the pump by providing ground

through pin 23 (blue wire) of the J1-B connector

and pin 2 (blue wire) of the oil pump connector.

Use

Evinrude Diagnostics

software to activate the

Oil Injector

test. This test starts the

EMM

control

function for the oil injection pump.

IMPORTANT:

This test is operating the pump

with 30 V on the system voltage (55 V) circuit. The

start assist circuit (SAC) of the

EMM

converts bat-

tery voltage (12 V) to 30 V of system voltage. Bat-

tery must be fully charged and connections must

be clean and tight. Pump activation should be

carefully confirmed. Listen for an audible click from

the oil injection pump when it is activated.

Use an inductive timing light to monitor current

flow through the ground circuit (blue wire) at the

oil pump connector (pin 2).

If the light flashes, the

EMM

and oil injection cir-

cuits are not at fault.

Refer to

Oil Injection Pump Voltage Tests

Oil Injection Pump Voltage Tests

Use a digital multimeter calibrated to a scale that

reads 55 V (DC) to measure voltage between the

oil pump electrical connector and engine ground.

Connect negative meter lead to ground.

Use an appropriate test probe to connect positive

meter lead to pin 2 (blue wire) of oil injection pump

electrical connector.

Turn the key switch to the ON position. Observe

voltage at pin 2.

•

Voltage at pin 2 should be approximately 30 V.

Static Tests Screen

1.

Oil injector test button

008579

1

Acceptable Oil Injection Pump

Test Readings

Key switch ON

approximately 30 VDC

Control signal

approximately 10 Hz

Engine running

approximately 55 VDC

1.

Oil injection pump connector (pin 2)

004344

1

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

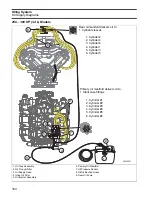

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

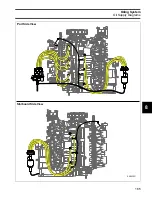

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

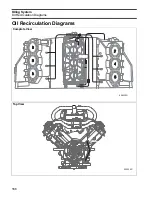

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

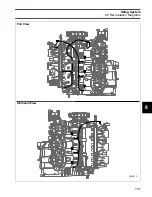

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...