Fuel System

Fuel System Tests

146

Lift Pump Vacuum Test

Confirm fuel supply to the fuel lift pump.

Temporarily install a vacuum gauge, T-fitting, and

8 in. (20.3 cm) of clear vinyl hose between the fuel

supply hose and fuel lift pump (inlet). Secure con-

nections with tie straps to prevent fuel or air leaks.

START outboard and run at FULL THROTTLE for

at least two minutes. Monitor clear vinyl hose for

the presence of air. Air bubbles indicate a faulty

hose, connection, or fuel tank pick-up. Repair, if

necessary, before proceeding.

There should be no air or vapor bubbles visible in

the clear hose. The maximum inlet fuel vacuum

should not exceed 4 in. Hg. (13.5 kPa) at the inlet

to the fuel lift pump under any operating condi-

tions (IDLE to WOT).

A higher vacuum indicates an excessive restric-

tion in the fuel supply. Repair as needed. Refer to

on p. 137 for fuel

supply component requirements.

Lift Pump Diaphragm Test

Perform this test only if a damaged pump is sus-

pected. This test does not check the performance

of internal fuel pump check valves.

Remove both pulse hoses from the crankcase fit-

tings.

Apply 15 psi (103 kPa) to each of the pulse hoses

of the pump. Replace lift pump if either side of

pump fails to hold pressure.

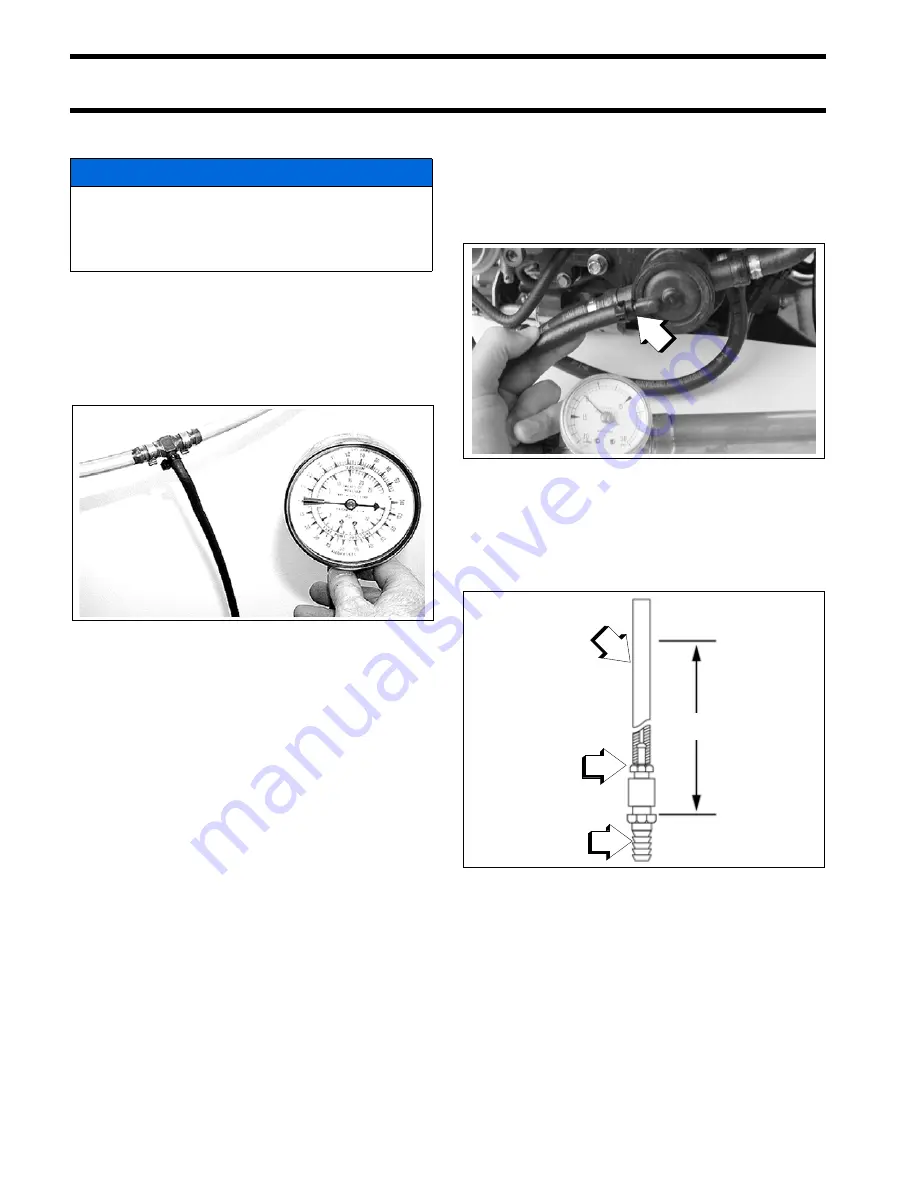

Anti-Siphon Valve Test

Remove anti-siphon valve from fuel tank. Install

adapter fittings and a 36 in. (91.4 cm) length of

clear hose to the inlet side (tank end) of valve.

Fill clear hose with water to a height of 20 in. (500

mm). Water must NOT flow through valve. An

occasional drip is acceptable. Replace valve if

water drips continuously.

Increase height of water to 25 in. (630 mm). Water

should flow through valve as water level reaches

25 in. (630 mm). Replace the anti-siphon valve if

test results are different.

NOTICE

Do not use fuel primer bulb, manual fuel

primer, or electric fuel pump primer to restart

outboard. A positive pressure in the fuel sup-

ply could damage some vacuum gauges.

000243

1.

Pulse fitting

000670

1.

Anti-siphon valve

2.

Adapter fitting

3.

Clear hose

DR2277

1

20 in. (500 mm)

3

2

1

Summary of Contents for EVINRUDE E-TEC BE225HGXABA

Page 163: ...Oiling System Oil Supply Diagrams 163 8 008208R Port Side View Starboard Side View ...

Page 165: ...Oiling System Oil Supply Diagrams 165 8 008432R Port Side View Starboard Side View ...

Page 167: ...Oiling System Oil Recirculation Diagrams 167 8 008207R Starboard View Port View ...

Page 251: ...Powerhead Powerhead Views 251 11 Powerhead Views Port Hose Routings 3 3 L models 007153 ...

Page 252: ...252 Powerhead Powerhead Views Starboard Hose Routings 3 3 L models 007154 ...

Page 253: ...Powerhead Powerhead Views 253 11 Port Hose Routings 3 4 L models 008503 ...

Page 254: ...254 Powerhead Powerhead Views Starboard Hose Routings 3 4 L models 008502 ...

Page 255: ...Powerhead Powerhead Views 255 11 Port 3 3 L models 008448 ...

Page 256: ...256 Powerhead Powerhead Views Starboard 3 3 L models 008449 ...

Page 257: ...Powerhead Powerhead Views 257 11 Port 3 4 L models 008441 ...

Page 258: ...258 Powerhead Powerhead Views Starboard 3 4 L models 008442 ...

Page 259: ...Powerhead Powerhead Views 259 11 Front 3 3 L models 008450 ...

Page 260: ...260 Powerhead Powerhead Views Front 3 4 L models 008439 ...

Page 261: ...Powerhead Powerhead Views 261 11 Rear 3 3 L models 007142 ...

Page 262: ...262 Powerhead Powerhead Views Rear 3 4 L models 008440 ...

Page 263: ...Powerhead Powerhead Views 263 11 Top 008438 ...

Page 264: ...264 Powerhead Powerhead Views Starboard ICON models 008504 ...

Page 269: ...Midsection Service Charts 269 12 Muffler 004117R ...

Page 320: ...S 322 ...