Asterion DC Multioutput ASA Series Operational Manual

M330516-01

2-16

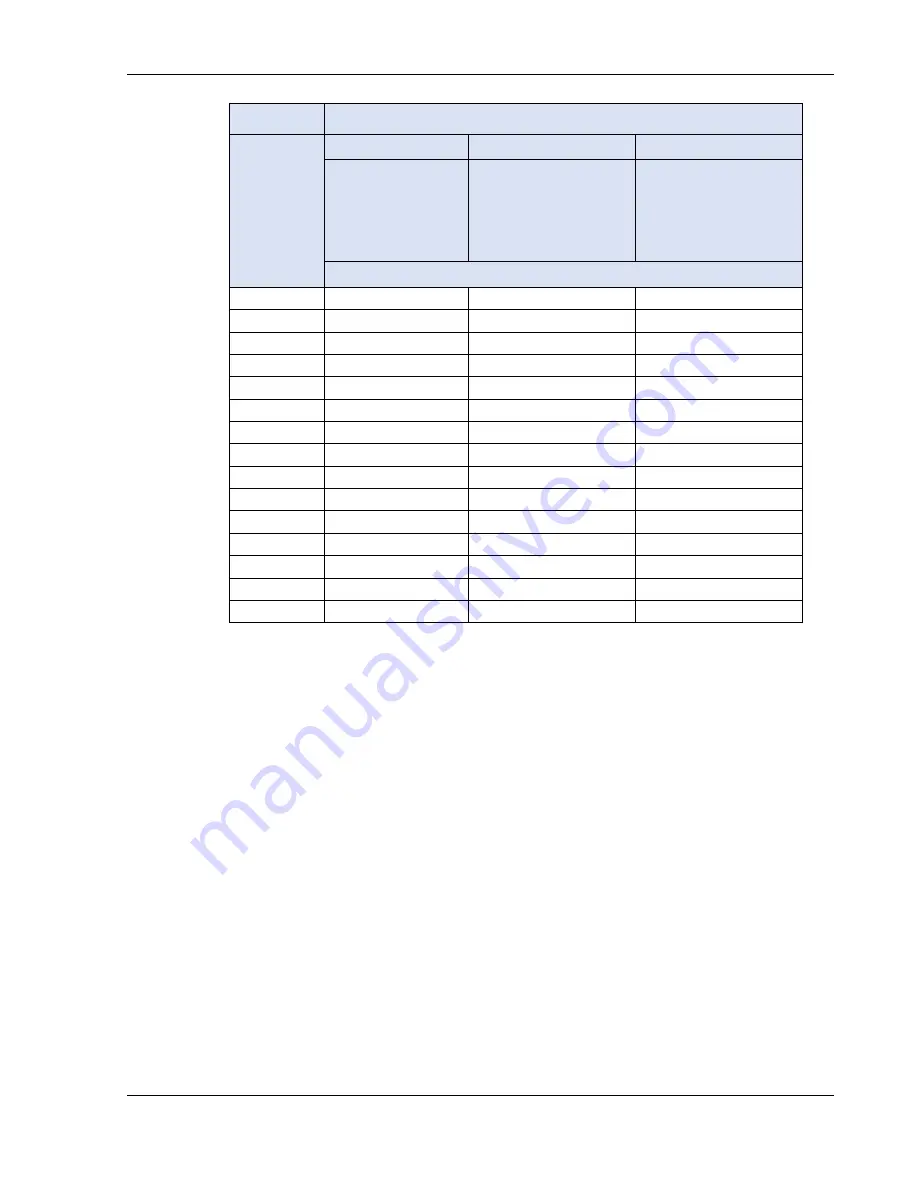

Size

Temperature Rating of Copper Conductor

AWG

60°C

75°C

90°C

Types: TW, UF

Types: RHW, THHW,

THW, THWN, XHHW,

USE, ZW

Types: TBS, SA, SIS,

FEP, FEPB, MI, RHH,

THHN, THHW, XHH,

XHHW

Current Rating, A(RMS)

18

−

−

14

16

−

−

18

14

15

20

25

12

20

25

30

10

30

35

40

8

40

50

55

6

55

65

75

4

70

85

95

3

85

100

115

2

95

115

130

1

110

130

145

0

125

150

170

00

145

175

195

000

165

200

225

0000

195

230

260

Table 2-8: Minimum Wire Size

When determining the optimum cable specification for your power applications, the

same engineering rules apply whether at the input or output of an electrical device.

Therefore, this guide applies equally to the input cable and output cable for this power

source and application loads.

Power cables must be able to safely carry maximum load current without overheating

or causing insulation degradation. It is important to power source performance to

minimize IR (voltage drop) loss within the cable. These losses have a direct effect on

the quality of power delivered to and from the power source and corresponding loads.

When specifying wire gauge, consider derating due to operating temperature at the

wire location. Wire gauge current capability and insulation performance drops with the

increased temperature developed within a cable bundle and with increased

environmental temperature. Therefore, short cables with derating of gauge size and

insulation properties are recommended for power source applications.

Be careful when using published commercial utility wiring codes. These codes are

designed for the internal wiring of homes and buildings and accommodate the safety

factors of wiring loss, heat, breakdown insulation, aging, etc. However, these codes

consider that up to 5% voltage drop is acceptable. Such a loss directly detracts from

the performance specifications of this power source. Also, consider how the wiring

codes apply to bundles of wire within a cable arrangement.