Step 4: Cutting Path

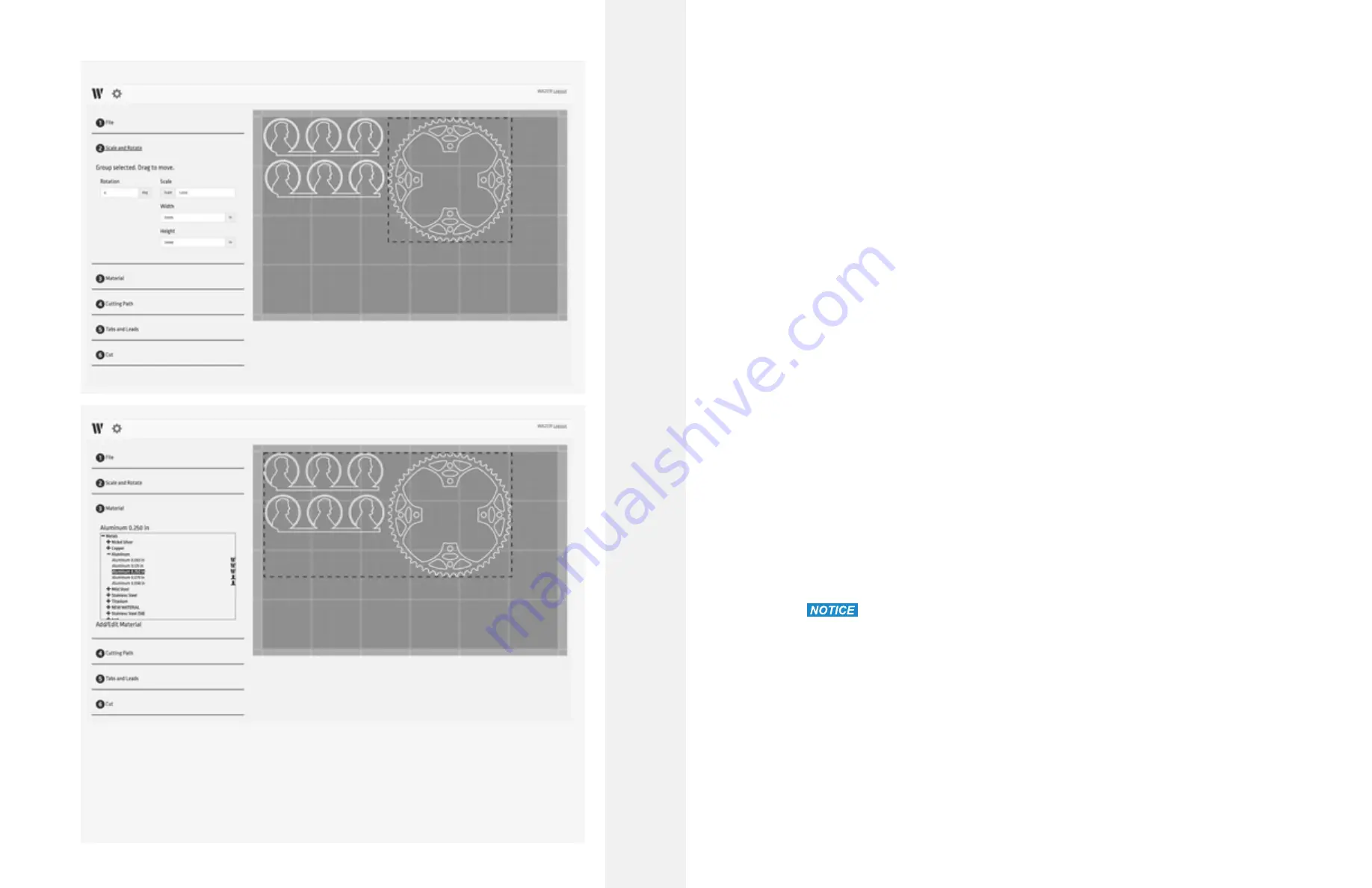

When a Design is imported into Wam it is simply a set of curves. These curves are shown in white.

To cut your parts properly, WAZER needs to know which side of the curve to Cut. As a result, the

Cut Path needs to be specified as either Outside or Inside.

Once you have made a selection, a green Cut Path appears around or within the white part

geometry.

This green line indicates the actual path of the WAZER. You can use it to check if your

Design will be Cut correctly.

It should be noted that there may be instances where you want to cut directly on the Cut Path. You

can specify this using the Centerline option. In this case, you will notice that the green Cut Path

completely covers the white geometry.

To aid in quick setup and accurate Outside and Inside Cut Paths, the software automatically

defaults the offset value based on the Jet size (you can change the default in the Wam options).

There may be instances where you desire an additional offset to make your Part slightly smaller

or slightly larger. To do this quickly, change the preloaded offset by the amount you would like to

oversize or undersize your Cut.

Step 5: Tabs and Leads

A Tab is small connection point between your Part and the Material from which it is being Cut,

designed to keep your Part in place for the duration of the Cut. Tabs help to increase overall

Accuracy and prevent Pop-Ups, which can cause the WAZER to jam and ruin your Cut.

Wam automatically defaults to incorporating Tabs in default locations of each Cut Path. The

location and size are designated on the Cut Group with a yellow indicator.

The default settings are that every Cut Path receives a single Tab of a size based on the Material.

This will likely be sufficient for most Cuts and will seldom need to be changed. However, you

should always review the default locations, in case they will cause problems with your Design.

If you need to make changes, select Manual Tab Placement and move the problem Tabs by left

clicking and dragging them. You can also add and remove Tabs by left clicking. Additionally, there

may be use cases where you cannot afford to place any Tabs, as a result you may want to select

No Tabs. This is highly discouraged, however, because it greatly increases the risk of poor or failed

Cuts.

A Lead refers to the distance that WAZER will be cutting away from the Cut Path. This is done to

make sure that the oversized Pierce at the start of a Cut doesn’t remove any excess material on

your Part. The Lead’s location and size are designated on the Virtual Cut Bed with a blue indicator.

Step 6: Finalize Cut

The last required selection in Wam is the Cut Quality. Cut Rate and Cut Quality have an inverse

relationship; a faster Cut leads to lower quality, and better quality requires a slower Cut.

Once you have selected Cut Quality, you can specify a file name and select the Generate Job File

Button to export the final Cut File. You can now move this Cut File to an SD Card and then insert

the SD Card into WAZER to begin the Cut.

•

Show stock size in the last tab -

This feature displays Raw material size required for the cut

in the cut section of WAM and helps you know the exact size of the raw material required

based on the current layout on the virtual bed. Multiple cuts on the virtual bed are also

considered while calculating the final raw material size.

When considering using No Tabs on a Cut, make sure you can afford a failure. There is a high

likelihood that these parts will come loose, resulting in them either falling into the Tank or jamming

the Nozzle.

Cr

eatin

g C

ut F

iles |

SE

C

TION 6

90

91