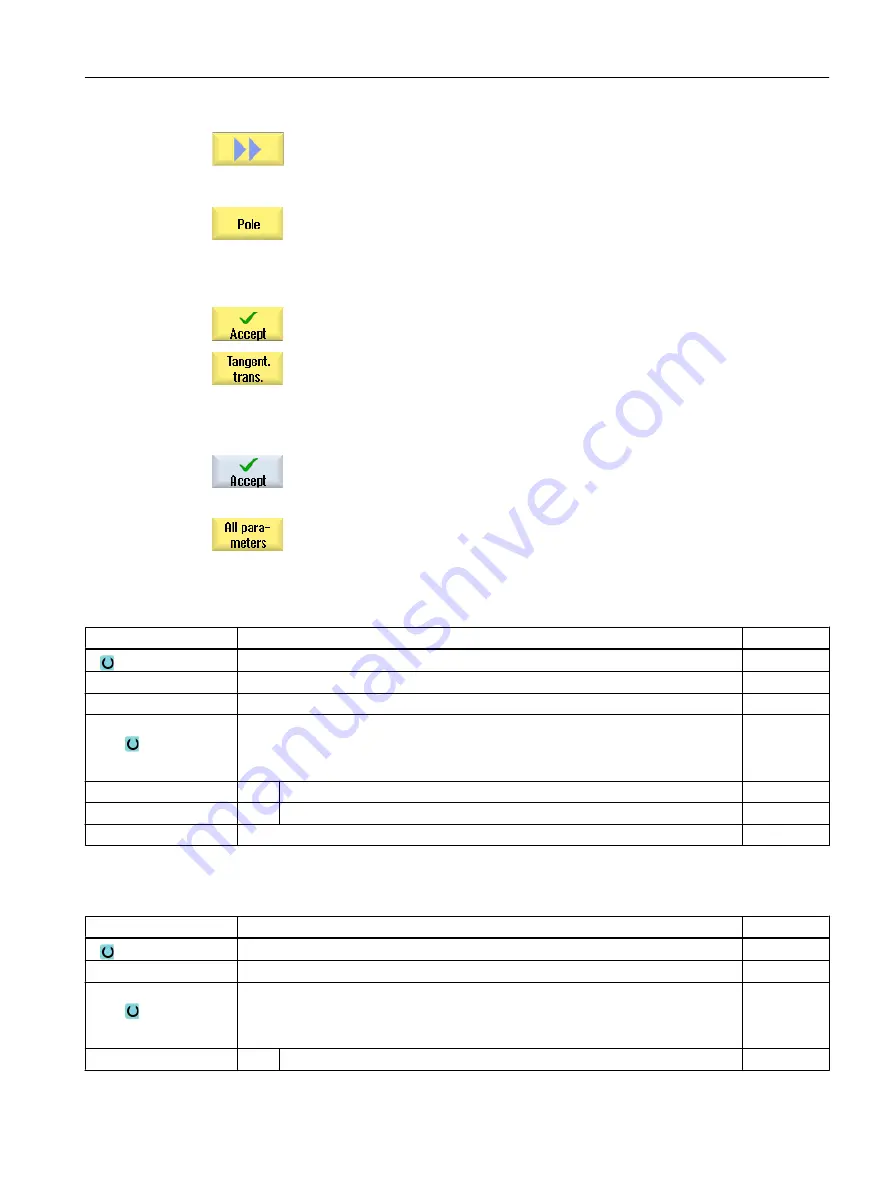

The "Pole Input" input window opens.

4.

Enter all the data available from the workpiece drawing in the input screen

(e.g. length of straight line, target position, transition to next element,

angle of lead, etc.).

5.

Press the "Accept" softkey.

The contour element is added to the contour.

6.

When entering data for a contour element, you can program the transition

to the preceding element as a tangent.

Press the "Tangent to prec. elem." softkey. The "tangential" selection

appears in the parameter α2 entry field.

7.

Repeat the procedure until the contour is complete.

8.

Press the "Accept" softkey.

The programmed contour is transferred into the process plan (program

view).

9.

If you want to display further parameters for certain contour elements,

e.g. to enter additional commands, press the "All parameters" softkey.

Contour element "Straight line, e.g. X"

Parameter

Description

Unit

X

End point X (abs or inc)

mm

α1

Starting angle e.g. to the X axis

Degrees

α2

Angle to the preceding element

Degrees

Transition to next ele‐

ment

Type of transition

● Radius

● Chamfer

Radius

R

Transition to following element - radius

mm

Chamfer

FS

Transition to following element - chamfer

mm

Additional commands

Additional G code commands

Contour element "straight line, e.g. Y"

Parameter

Description

Unit

Y

End point Y (abs or inc)

mm

α1

Starting angle to X axis

Degrees

Transition to next ele‐

ment

Type of transition

● Radius

● Chamfer

Radius

R

Transition to following element - radius

mm

Programming technological functions (cycles)

10.3 Contour milling

Milling

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

487

Содержание SINUMERIK 828D Turning

Страница 68: ...Introduction 2 4 User interface Milling 68 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 162: ...Setting up the machine 4 12 MDA Milling 162 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 270: ...Machining the workpiece 6 17 Setting for automatic mode Milling 270 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 278: ...Swivel combination 45 90 Simulating machining 7 1 Overview Milling 278 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 294: ...Simulating machining 7 9 Displaying simulation alarms Milling 294 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 316: ...Generating a G code program 8 10 Measuring cycle support Milling 316 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 684: ...Collision avoidance 12 2 Set collision avoidance Milling 684 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 746: ...Tool management 13 16 Working with Multitool Milling 746 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 830: ...Alarm error and system messages 15 9 Remote diagnostics Milling 830 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 846: ... Working with Manual Machine 16 7 More complex machining Milling 846 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 870: ...HT 8 840D sl only 18 5 Calibrating the touch panel Milling 870 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 890: ...Easy Message 828D only 20 7 Making settings for Easy Message Milling 890 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 924: ...Edit PLC user program 828D only 23 8 Searching for operands Milling 924 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 925: ...Appendix A A 1 840D sl 828D documentation overview Milling Operating Manual 08 2018 6FC5398 7CP41 0BA0 925 ...