Program blocks can be created in two stages. This means that additional blocks can be formed

within a particular block.

You then have the option of opening and closing these blocks depending on your

requirement.

Display

Meaning

Text

Block designation

Spindle

● Select the spindle

Defines at which spindle a program block is to be executed.

Addit. run-in code

● Yes

If the block is not executed because the specified spindle should not be

processed, it is possible to temporarily activate a so-called "Additional run-

in code".

● No

Automat. retraction

● Yes

Block start and block end are moved to the tool change point, i.e. the tool

is brought into a safe range.

● No

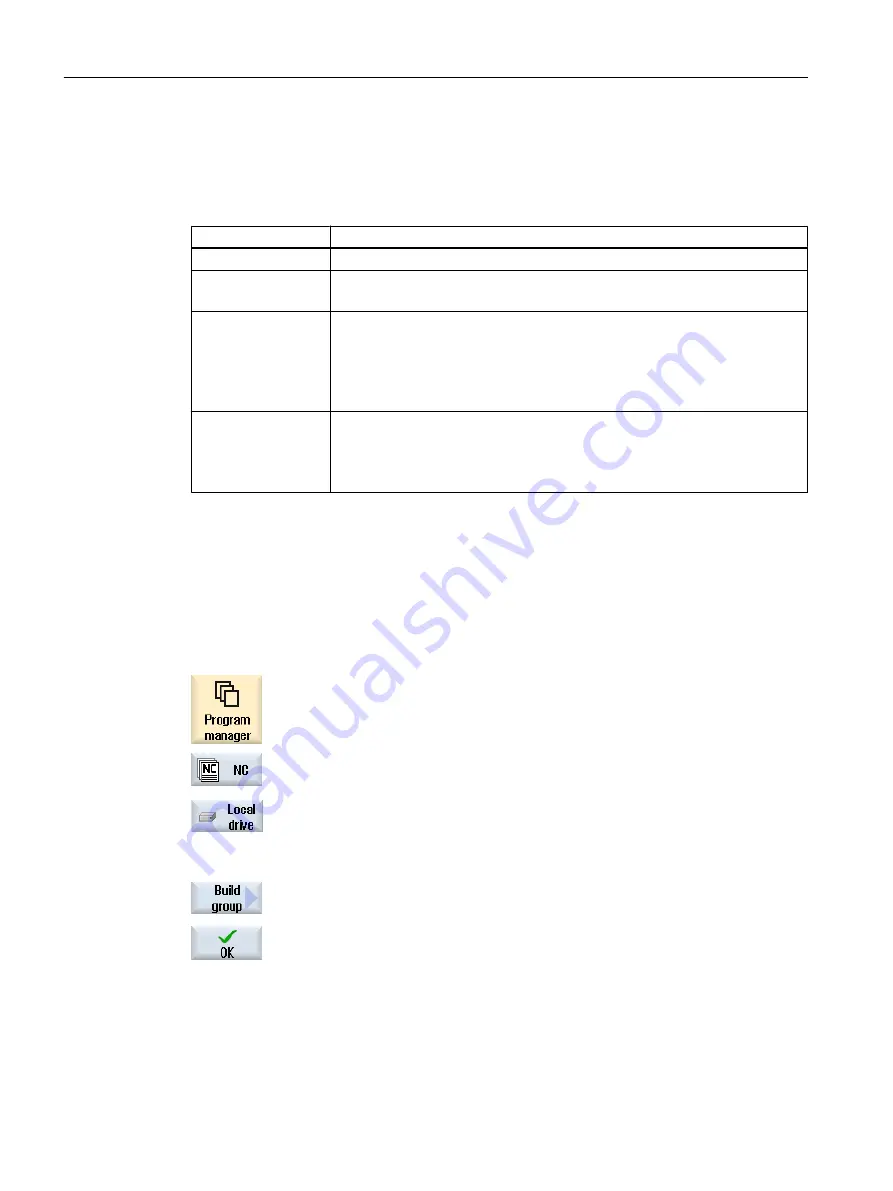

Structuring programs

● Before generating the actual program, generate a program frame using empty blocks.

● By forming blocks, structure existing G code or ShopMill programs.

Procedure

1.

Select the "Program manager" operating area.

2.

Select the storage location and create a program or open a program.

The program editor opens.

3.

Select the required program blocks that you wish to combine to form a

block.

4.

Press the "Form block" softkey.

The "Form New Block" window opens.

5.

Enter a designation for the block, assign the spindle, if required, select

the Additional run-in code and the automatic retraction and then press

the "OK" softkey.

Opening and closing blocks

Machining the workpiece

6.10 Editing a program

Milling

220

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

Содержание SINUMERIK 828D Turning

Страница 68: ...Introduction 2 4 User interface Milling 68 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 162: ...Setting up the machine 4 12 MDA Milling 162 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 270: ...Machining the workpiece 6 17 Setting for automatic mode Milling 270 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 278: ...Swivel combination 45 90 Simulating machining 7 1 Overview Milling 278 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 294: ...Simulating machining 7 9 Displaying simulation alarms Milling 294 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 316: ...Generating a G code program 8 10 Measuring cycle support Milling 316 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 684: ...Collision avoidance 12 2 Set collision avoidance Milling 684 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 746: ...Tool management 13 16 Working with Multitool Milling 746 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 830: ...Alarm error and system messages 15 9 Remote diagnostics Milling 830 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 846: ... Working with Manual Machine 16 7 More complex machining Milling 846 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 870: ...HT 8 840D sl only 18 5 Calibrating the touch panel Milling 870 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 890: ...Easy Message 828D only 20 7 Making settings for Easy Message Milling 890 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 924: ...Edit PLC user program 828D only 23 8 Searching for operands Milling 924 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 925: ...Appendix A A 1 840D sl 828D documentation overview Milling Operating Manual 08 2018 6FC5398 7CP41 0BA0 925 ...