If the workpiece programming requires it, you can display and change all of the parameters

using "Input complete".

Approach/retraction for vortex milling

1. The tool approaches the starting point in front of the slot in rapid traverse and maintains

the safety clearance.

2. The tool goes to the cutting depth.

3. The open slot is always machined along its entire length using the selected machining

method.

4. The tool retracts to the safety clearance in rapid traverse.

Approach/retraction for plunge cutting

1. The tool moves in rapid traverse to the starting point in front of the slot at the safety

clearance.

2. The open slot is always machined along its entire length using the selected machining

method.

3. The tool retracts to the safety clearance in rapid traverse.

Machining type, roughing vortex milling

Roughing is performed by moving the milling cutter along a circular path.

While performing this motion, the milling cutter is continuously fed into the plane. Once the

milling cutter has traveled along the entire slot, it returns to its starting point, while continuing

to move in a circular fashion. By doing this, it removes the next layer (infeed depth) in the Z

direction. This process is repeated until the set slot depth plus the finishing allowance has

been reached.

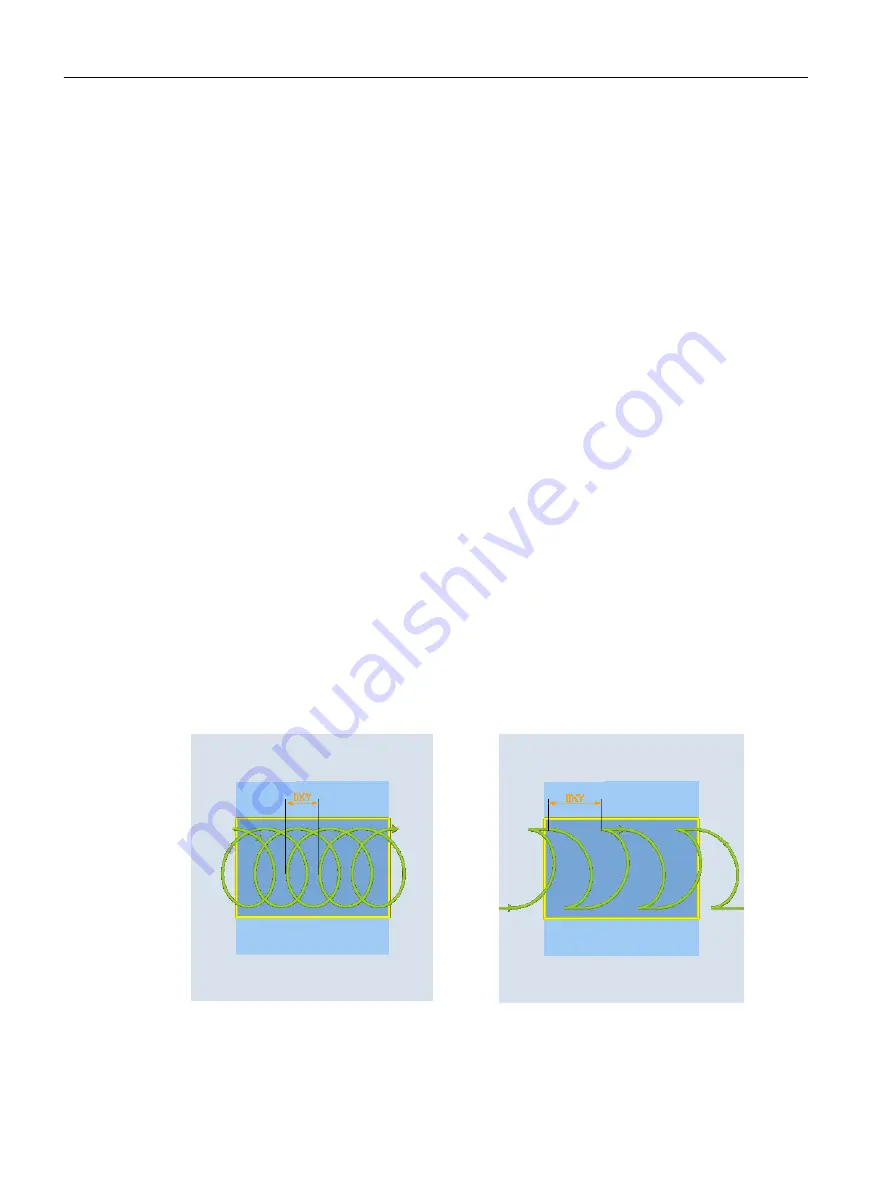

Vortex milling: Down-cut or up-cut

Vortex milling: Down-cut-up-cut

Programming technological functions (cycles)

10.2 Milling

Milling

462

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

Содержание SINUMERIK 828D Turning

Страница 68: ...Introduction 2 4 User interface Milling 68 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 162: ...Setting up the machine 4 12 MDA Milling 162 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 270: ...Machining the workpiece 6 17 Setting for automatic mode Milling 270 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 278: ...Swivel combination 45 90 Simulating machining 7 1 Overview Milling 278 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 294: ...Simulating machining 7 9 Displaying simulation alarms Milling 294 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 316: ...Generating a G code program 8 10 Measuring cycle support Milling 316 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 684: ...Collision avoidance 12 2 Set collision avoidance Milling 684 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 746: ...Tool management 13 16 Working with Multitool Milling 746 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 830: ...Alarm error and system messages 15 9 Remote diagnostics Milling 830 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 846: ... Working with Manual Machine 16 7 More complex machining Milling 846 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 870: ...HT 8 840D sl only 18 5 Calibrating the touch panel Milling 870 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 890: ...Easy Message 828D only 20 7 Making settings for Easy Message Milling 890 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 924: ...Edit PLC user program 828D only 23 8 Searching for operands Milling 924 Operating Manual 08 2018 6FC5398 7CP41 0BA0 ...

Страница 925: ...Appendix A A 1 840D sl 828D documentation overview Milling Operating Manual 08 2018 6FC5398 7CP41 0BA0 925 ...