31. FA TRANSPARENT FUNCTION

31.6 Personal Computer Side Setting

31 - 35

28

ENERG

Y MEAS

URIN

G UNIT

/

ELECT

RIC M

UL

TI-

MEAS

UR

ING

INSTRUMENT

CO

NNECT

IO

N

29

GO

T

MUL

T

I-

DRO

P

CONNECTION

30

M

U

LT

I-

CH

A

N

NE

L

FUNCTION

31

FA

TRANS

P

ARENT

FUNCTION

32

CONNECTION

T

O

IA

I

ROBOT CONT

ROLLE

R

33

C

O

NNECTION T

O

OMRON PLC

34

CO

N

N

EC

TI

O

N

T

O

O

M

R

O

N T

E

MPER

TU

RE

C

O

NT

ROL

LE

R

35

CONNECTION T

O

KEY

ENCE PLC

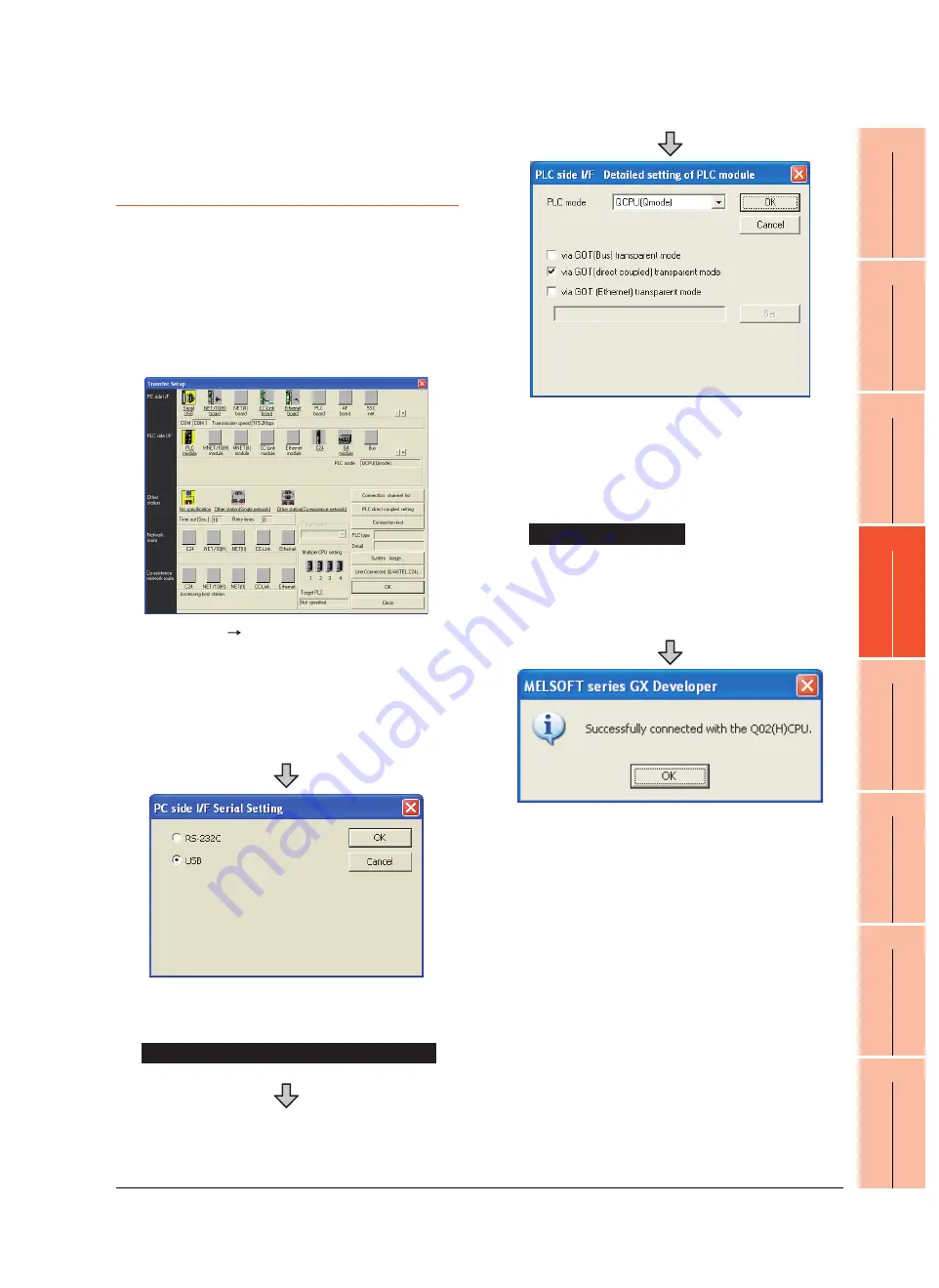

31.6.3 Accessing the PLC by the GX

Developer, PX Developer, GX

Configurator

The following shows the procedure to set the FA

transparent function of GX Developer.

GX Configurator is an add-on software of GX Developer.

(Except for GX Configurator-QP)

Connecting the GOT and PLC in direct

connection (when connecting to QCPU (Q

mode))

1.

Click [Online]

[Read from PLC] in GX Developer.

2.

Set the [PLC Series] to [QCPU(Q mode)].

3.

The [Transfer Setup] is displayed.

4.

Set the [Transfer Setup]:

PC side I/F

: Serial USB (COM)

PLC side I/F

: PLC module

Other station

: No specification

5.

Double-click [Serial] of the PC side I/F to display [PC

side I/F Serial setting].

6.

Check the following for [PC side I/F Serial setting].

Mark the [USB] checkbox.

When connecting the GOT and PC with USB

7.

Double-click [PLC module] of the PLC side I/F to

display [PLC side I/F Detailed setting of PLC module].

8.

Check-mark the following in [PLC side I/F Detailed

setting of PLC module].

*1

Mark the [via GOT(direct coupled) transparent mode]

checkbox.

*1

This is operation required in the case of using GX Developer

of which version is 8.22Y and above.

9.

The screen returns to [Transfer Setup]. Click

[Connection Test] to check if GX Developer has been

connected to the QCPU (Q mode).

Direct CPU connection

Содержание GT16

Страница 1: ......

Страница 2: ......

Страница 46: ...1 4 1 OVERVIEW 1 1 Features ...

Страница 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Страница 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Страница 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Страница 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Страница 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Страница 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Страница 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Страница 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Страница 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Страница 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Страница 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Страница 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Страница 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Страница 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Страница 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Страница 422: ...REVISIONS 4 ...

Страница 425: ......

Страница 426: ......

Страница 427: ......

Страница 428: ......

Страница 470: ......

Страница 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Страница 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Страница 584: ......

Страница 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Страница 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Страница 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Страница 648: ......

Страница 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Страница 660: ......

Страница 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Страница 676: ......

Страница 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Страница 744: ......

Страница 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Страница 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Страница 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Страница 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Страница 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Страница 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Страница 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Страница 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Страница 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Страница 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Страница 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Страница 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Страница 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Страница 1131: ...MICROCOMPUTER CONNECTION 61 MICROCOMPUTER CONNECTION SERIAL 61 1 62 MICROCOMPUTER CONNECTION ETHERNET 62 1 ...

Страница 1132: ......

Страница 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Страница 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Страница 1272: ......

Страница 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Страница 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Страница 1294: ......

Страница 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Страница 1302: ...REVISIONS 4 ...

Страница 1305: ......

Страница 1306: ......