6. OPTION

6.4 Battery

6 - 5

1

OV

ER

VI

EW

2

SY

STEM

CONFIGURA

TION

3

SP

ECI

F

IC

A

T

IO

NS

4

PA

R

T

S

N

A

M

E

5

UL, c

U

L

S

TANDARDS

A

N

D

E

MC

DIRECTIVE

6

OP

TIO

N

7

INST

ALL

A

TI

ON

8

COMMUNICA

TION

CABLE

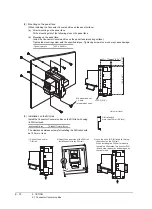

6.4 Battery

The battery backs up clock data and data stored in the built-in RAM (D drive) including maintenance report, and system

log data. A battery is installed to Handy GOT when Handy GOT is shipped from the factory.

6.4.1

Applicable battery

The following battery is applicable for Handy GOT.

For details on the battery specifications, refer to the following.

6.4.2

Battery replacement procedure

Periodically replace a battery with reference to “3.4 Battery specifications”.

Model

Contents

GT15-BAT

Battery for clock data and maintenance report system log data backups

1.

After keeping the GOT turned ON more than

10 minutes, turn OFF the GOT.After turning

OFF the GOT, perform the procedure

to

within 5 minutes.

2.

Loosen the environmental protection back

cover screws at two points on GOT rear face to

remove the cover.

3.

Remove the old battery from the holder and

disconnect the connecter.

4.

Insert the connector of the new battery.

5.

Install the battery to the GOT.

6.

Attach the environmental protection back

cover and tighten the screws.

Tightening torque: 0.36 to 0.48 N•m

Too much tightening may cause damage.

7.

Turn the GOT power on.

8.

Check if the battery condition is normal with

the utility.

Refer to the following for the details of battery

status display.

11.1 GOT Main Unit Function Settings

Environmental

protection

back cover

screw

Connector for

battery connection

Battery

Insert the red lead as

to pass it through the

notch on the circuit board.

Circuit

board

Insertion

direction

Lead (Black)

Lead (Red)

Battery

Environmental

protection

back cover

screw

Содержание GT16

Страница 1: ......

Страница 2: ......

Страница 46: ...1 4 1 OVERVIEW 1 1 Features ...

Страница 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Страница 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Страница 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Страница 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Страница 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Страница 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Страница 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Страница 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Страница 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Страница 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Страница 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Страница 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Страница 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Страница 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Страница 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Страница 422: ...REVISIONS 4 ...

Страница 425: ......

Страница 426: ......

Страница 427: ......

Страница 428: ......

Страница 470: ......

Страница 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Страница 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Страница 584: ......

Страница 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Страница 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Страница 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Страница 648: ......

Страница 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Страница 660: ......

Страница 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Страница 676: ......

Страница 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Страница 744: ......

Страница 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Страница 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Страница 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Страница 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Страница 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Страница 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Страница 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Страница 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Страница 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Страница 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Страница 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Страница 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Страница 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Страница 1131: ...MICROCOMPUTER CONNECTION 61 MICROCOMPUTER CONNECTION SERIAL 61 1 62 MICROCOMPUTER CONNECTION ETHERNET 62 1 ...

Страница 1132: ......

Страница 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Страница 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Страница 1272: ......

Страница 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Страница 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Страница 1294: ......

Страница 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Страница 1302: ...REVISIONS 4 ...

Страница 1305: ......

Страница 1306: ......