64. MODBUS(R)/TCP CONNECTION

64.6 Connection Example

64 - 9

60

CONNECTION T

O

MURA

T

E

C

CONTROLL

ER

61

MI

C

R

O

C

OMPUTER

CONNECTION

(SE

R

IA

L)

62

MICR

OCOMPUTER

CONNECTION

(E

T

HE

RN

E

T)

63

MO

D

B

US(R)/

R

T

U

CONNE

C

T

ION)

64

MO

DBUS(R)/

TCP

CON

N

E

C

T

ION

65

V

NC(R) S

E

R

V

E

R

CONNECTION

PLC side setting

Make the communication settings as shown below. For

details of the communication settings, refer to the

peripheral software manual for YOKOGAWA PLC.

POINT

POINT

POINT

Connection between STARDOM and the PC for

communication settings

For the communication settings of STARDOM,

STARDOM and the PC for communication settings

must be connected to Ethernet using the Resource

Configurator (peripheral software).

(1) Modbus Communication Portfolio License

To set the communication settings for STARDOM, an

installation of Modbus Communication Portfolio License

is required.

For details on the communication settings, refer to the

following manual.

STARDOM FCN/FCJ Guide

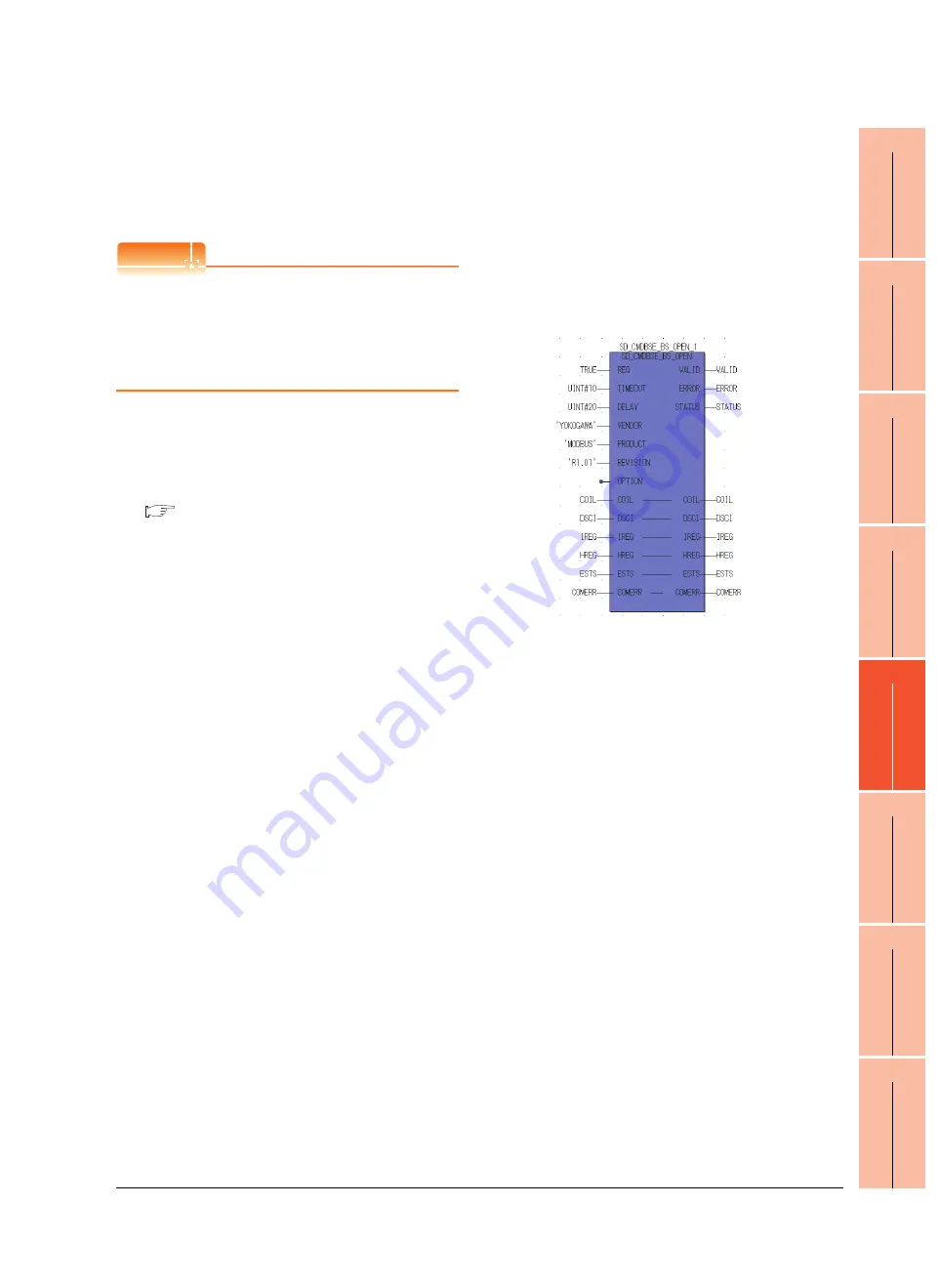

(2) Defining Logic POU

Define Logic POU using Logic Designer (peripheral

software), and download the project to STARDOM.

(a) Start Logic Designer and create a new project

using a template.

Use [STARDOM Serial Communication] template.

(b) Insert Firmware Library to the new project.

• Right-click [Library] under the project tree in Logic

Designer.

• Right-click [Insert] and select [Firmware Library].

• Double-click the [SD_FCXPLCE_LIB] folder and

double-click [SD_FCXPLCE_LIB.fwl] to select it.

• The library path inserted in the procedures above

is as follows.

{Install Folder}\LogicDesigner\Mwt\Plc\Fw_lib\

SD_FCXPLCE_LIB\SD_FCXPLCE_LIB.fwl

(c) Insert User Library to the new project.

• Right-click [Library] under the project tree in Logic

Designer.

• Right-click [Insert] and select [User Library].

• Double-click [SD_CMODBUSE_PF.mwt],

[SD_CUTIL_PF.mwt] and

[SD_CMODBUSS_PF.mwt] to select it.

• (When [STARDOM Serial Communication] is

used for the template, [SD_CUTIL_PF.mwt] is

inserted as default.)

• The library path inserted in the procedures above

is as follows.

{InstallFolder}\LogicDesigner\Libraries\

SD_CMODBUSE_PF.mwt

{Install Folder}\LogicDesigner\Libraries\

SD_CUTIL_PF.mwt

{Install Folder}\LogicDesigner\Libraries\

SD_CMODBUSS_PF.mwt

(d) Copy a sample project POU to the new project.

• Open "SD_CMODBUSE_Sample1.mwt".

• Right-click [ComEServerModbus*] in the Logic

POU under the project tree in the

SD_CMODBUSE_Sample1 project, and select

[Copy].

• Right-click the [Logic POU] under the project tree

in the previously created project, and select

[Paste].

• Double-click the [ComEServerModbus*] file in the

[ComEServerModbus*] folder.

• For the following terminals, set as shown below.

(e) Set devices to be monitored by a GOT.

• Right-click the [ComEServerModbus*] file in the

[ComEServerModbus*] folder in the logic POU

under the project tree and select [Insert] - [Cord

worksheet].

• Set the variable devices to be monitored.

(f) Defining the instance

Instantiate Logic POU. Define an already defined

instance to Task0.

• Right-click the [Physical

hardware][Configuration:IPC_40/FCX01:FCX/

Tasks/Task0:CYCLIC] and select [Insert] -

[Program instance].

• Define the program instance name and select

ComEServerModbus for the program type.

(g) Defining Target Setting

Define the IP address of STARDOM to set the

communication settings.

Double-click [Physical

hardware][Configuration:IPC_33/FCX01:FCX/

Target Setting] and input the IP address or the host

name.

(h) Downloading the project

• Execute [Build] - [Make].

(Same as when pressing the function key F9).

• Download after confirming that the compile error

does not occur. Select [Download] in the project

control dialog displayed when [Online] - [Project

control] is selected.

• When the download is completed, select [Cold]

and start STARDOM.

Содержание GT16

Страница 1: ......

Страница 2: ......

Страница 46: ...1 4 1 OVERVIEW 1 1 Features ...

Страница 54: ...2 8 2 SYSTEM CONFIGURATION 2 2 System Equipment ...

Страница 60: ...3 6 3 SPECIFICATIONS 3 4 Battery specifications ...

Страница 72: ...5 8 5 UL cUL STANDARDS AND EMC DIRECTIVE 5 2 EMC Directive ...

Страница 102: ...6 30 6 OPTION 6 7 Connector Conversion Box ...

Страница 106: ...7 4 7 INSTALLATION 7 1 Installing Procedure ...

Страница 110: ...8 4 8 COMMUNICATION CABLE 8 1 Overview of Communication Cable ...

Страница 130: ...9 20 9 HANDLING OF POWER WIRING AND SWITCH 9 4 Switch Wiring ...

Страница 142: ...10 12 10 UTILITY FUNCTION 10 3 Utility Display ...

Страница 184: ...11 42 11 DISPLAY AND OPERATION SETTINGS GOT SET UP 11 4 Maintenance Function ...

Страница 202: ...12 18 12 COMMUNICATION INTERFACE SETTING COMMUNICATION SETTING 12 3 Ethernet Setting ...

Страница 226: ...13 24 13 DEBUG 13 3 Memory Data Control ...

Страница 248: ...14 22 14 SELF CHECK 14 2 Batch Self Check ...

Страница 350: ...15 102 15 DATA CONTROL 15 3 OS Project Information ...

Страница 410: ...19 22 19 TROUBLESHOOTING 19 2 Error Message and System Alarm ...

Страница 418: ...App 8 APPENDICES Appendix 3 Transportation Precautions ...

Страница 422: ...REVISIONS 4 ...

Страница 425: ......

Страница 426: ......

Страница 427: ......

Страница 428: ......

Страница 470: ......

Страница 510: ...21 22 21 COMPUTER LINK CONNECTION 21 6 Precautions ...

Страница 568: ...22 58 22 ETHERNET CONNECTION 22 5 Precautions ...

Страница 584: ......

Страница 626: ...25 14 25 SERVO AMPLIFIER CONNECTION 25 7 Precautions ...

Страница 632: ...26 6 26 ROBOT CONTROLLER CONNECTION 26 6 Precautions ...

Страница 647: ...MULTIPLE GOT CONNECTIONS 29 GOT MULTI DROP CONNECTION 29 1 ...

Страница 648: ......

Страница 659: ...MULTI CHANNEL FUNCTION 30 MULTI CHANNEL FUNCTION 30 1 ...

Страница 660: ......

Страница 675: ...FA TRANSPARENT FUNCTION 31 FA TRANSPARENT FUNCTION 31 1 ...

Страница 676: ......

Страница 742: ...31 66 31 FA TRANSPARENT FUNCTION 31 7 Precautions ...

Страница 744: ......

Страница 766: ...32 22 32 CONNECTION TO IAI ROBOT CONTROLLER 32 7 Precautions ...

Страница 802: ...34 10 34 CONNECTION TO OMRON TEMPERATURE CONTROLLER 34 7 Precautions ...

Страница 834: ...36 18 36 CONNECTION TO KOYO EI PLC 36 6 Device Range that Can Be Set ...

Страница 858: ...38 12 38 CONNECTION TO SHARP PLC 38 6 Device Range that Can Be Set ...

Страница 868: ...39 10 39 CONNECTION TO SHINKO TECHNOS INDICATING CONTROLLER 39 7 Precautions ...

Страница 902: ...42 6 42 CONNECTION TO TOSHIBA MACHINE PLC 42 6 Device Range that Can Be Set ...

Страница 908: ...43 6 43 CONNECTION TO PANASONIC SERVO AMPLIFIER 43 7 Precautions ...

Страница 970: ...48 12 48 CONNECTION TO FUJI TEMPERATURE CONTROLLER 48 7 Precautions ...

Страница 1052: ...52 26 52 CONNECTION TO AZBIL CONTROL EQUIPMENT 52 7 Precautions ...

Страница 1102: ...55 14 55 CONNECTION TO GE PLC 55 7 Precautions ...

Страница 1114: ...57 4 57 CONNECTION TO SICK SAFETY CONTROLLER 57 5 Device Range that Can Be Set ...

Страница 1128: ...59 2 59 CONNECTION TO HIRATA CORPORATION HNC CONTROLLER ...

Страница 1130: ...60 2 60 CONNECTION TO MURATEC CONTROLLER ...

Страница 1131: ...MICROCOMPUTER CONNECTION 61 MICROCOMPUTER CONNECTION SERIAL 61 1 62 MICROCOMPUTER CONNECTION ETHERNET 62 1 ...

Страница 1132: ......

Страница 1270: ...62 68 62 MICROCOMPUTER CONNECTION ETHERNET 62 8 Precautions ...

Страница 1271: ...MODBUS CONNECTIONS 63 MODBUS R RTU CONNECTION 63 1 64 MODBUS R TCP CONNECTION 64 1 ...

Страница 1272: ......

Страница 1292: ...64 12 64 MODBUS R TCP CONNECTION 64 7 Precautions ...

Страница 1293: ...CONNECTIONS TO PERIPHERAL EQUIPMENT 65 VNC R SERVER CONNECTION 65 1 ...

Страница 1294: ......

Страница 1298: ...65 4 65 VNC R SERVER CONNECTION 65 4 Setting in Personal Computer ...

Страница 1302: ...REVISIONS 4 ...

Страница 1305: ......

Страница 1306: ......