4-2

●

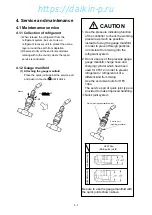

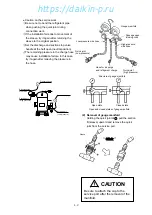

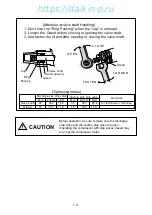

Caution on the service work

q

Be sure not to bend the refrigerant pipe

when pushing the quick joint during

connection work.

w

If the installation fails due to movement of

the sleeve, try it again after returning the

sleeve to the original position.

e

Set the discharge and suction stop valve

handle at the half open (neutral position).

r

The remaining pressure in the charge hose

may cause installation failure. In this case,

try it again after relieving the pressure in

the hose.

CAUTION

Be sure to attach the cap to the

service port after the removal of the

manifold.

(2) Removal of gauge manifold

Holding the quick joint at A , pull the section

B (sleeve) upward and remove the quick

joint from the service port.

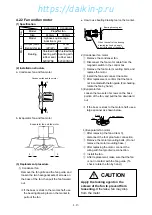

Gauge manifold

Passage open-

/closing cock

High-pressure

side hose

Low-pressure side hose

Quick joint

(Low pressure)

Hose for air purge

and refrigerant charge

Structure of gauge manifold

Open state

Closed state

Open and closed states of gauge manifold

Quick joint

(high pressure)

Sleeve

Click

Pressure gauge

Compound gauge

Service port

(Low pressure)

Discharge side

stop valve

Service port

(High pressure)

https://daikin-p.ru

Содержание LXE10E-1

Страница 161: ...7 9 https daikin p ru ...

Страница 162: ...7 14 Schematic wiring diagram LXE10E 1 7 10 https daikin p ru ...

Страница 163: ...7 15 Stereoscopic wiring diagram LXE10E 1 7 11 https daikin p ru ...