4-23

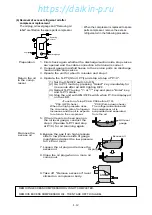

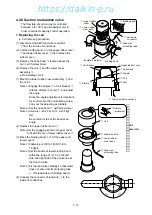

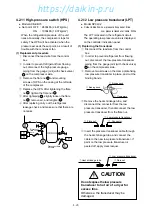

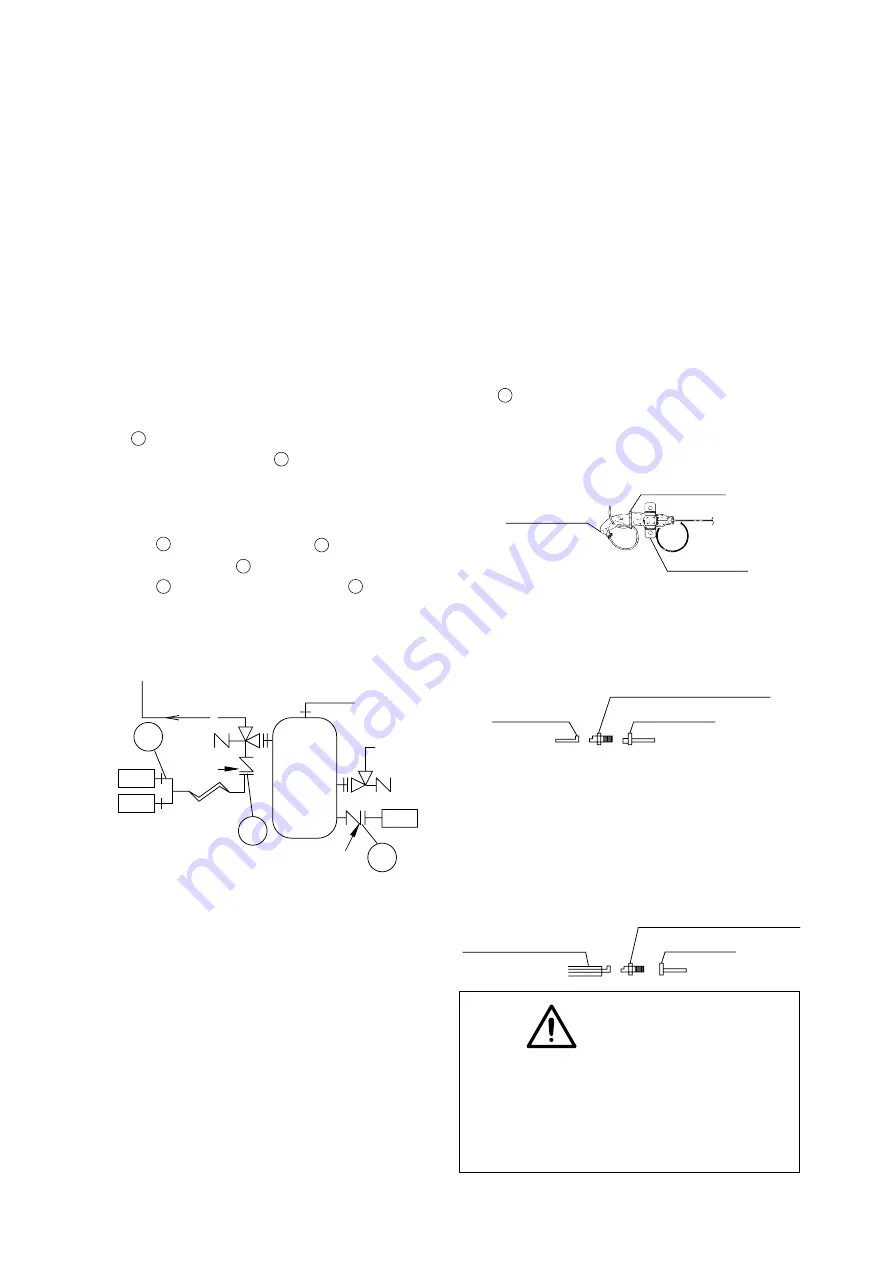

4.2.11 High-pressure switch (HPS)

●

Model ACB-KB15

●

Set point OFF : 2400kPa (24.47kg/cm

2

)

ON

: 1900kPa (19.37kg/cm

2

)

When the refrigeration pressure of the unit

rises abnormally, the compressor stops for

safety. The HPS will be activated when the

pressure exceeds the set point, as a result of

trouble with the condenser fan.

(1) Replacement procedure

q

Disconnect the lead wire from the control

box.

w

In order to prevent refrigerant from flowing

out, disconnect the high-pressure gauge

piping from the gauge joint (with check valve)

A on the compressor side.

e

Remove the flare nut B and mounting

screws of HPS on the casing at the left side

of the compressor.

r

Replace the HPS. After tightening the flare

nut B , tighten the flare nut A .

t

After tightening A , slightly loosen the flare

nut B , remove air, and retighten B .

y

After replacing carry out the refrigerant

leakage check, and make sure that there are

no leaks.

Disconnect

flare nut

here

Disconnect flare

nut here

B

A

C

COMPRESSOR

L P T

H P T

H P S

D

CAUTION

Do not expose the low pressure

transducer to hot air of a dryer for

excess time.

Otherwise, the transducer may be

damaged.

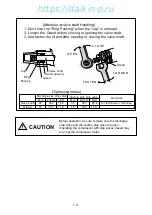

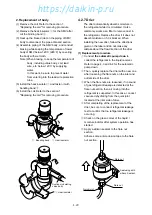

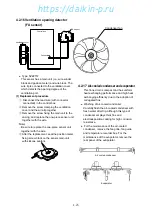

4.2.12 Low pressure transducer (LPT)

●

Model SPCL02

●

Colour indication: Low pressure transducer: Blue

Low pressure transducer: cable: White

The LPT is located in the refrigerant circuit.

The operating low pressure value is displayed

on the controller indication panel.

(1) Replacing the transducer

q

Disconnect the lead wire from the control

box.

w

In order to prevent refrigerant from flowing

out, disconnect the low-pressure transducer

piping from the gauge joint (with check valve)

C on the compressor side.

e

Remove two screws on the clamp plate fixing

low pressure transducer in place, and cut the

binding bands.

t

Insert the pressure transducer cable through

the heat shrinkage tube, and connect the

cable to the new low pressure transducer. If

paint on the low pressure transducer is

peeled off, apply clear lacquer.

r

Remove the heat shrinkage tube, and

disconnect the connector from the low

pressure transducer, then disconnect the low

pressure transducer from the flare nut.

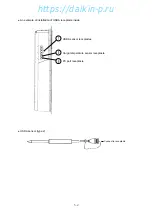

q

Clamp plate

w

Binding band

w

Binding band

e

Connector

q

Low pressure transducer

w

Flare nut

e

Flare nut

q

Heat shrinkage tube

w

Low pressure transducer

https://daikin-p.ru

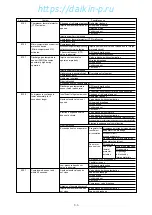

Содержание LXE10E-1

Страница 161: ...7 9 https daikin p ru ...

Страница 162: ...7 14 Schematic wiring diagram LXE10E 1 7 10 https daikin p ru ...

Страница 163: ...7 15 Stereoscopic wiring diagram LXE10E 1 7 11 https daikin p ru ...