6-3

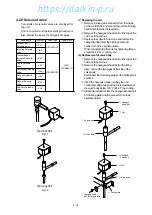

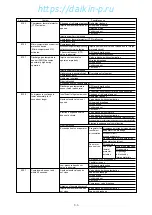

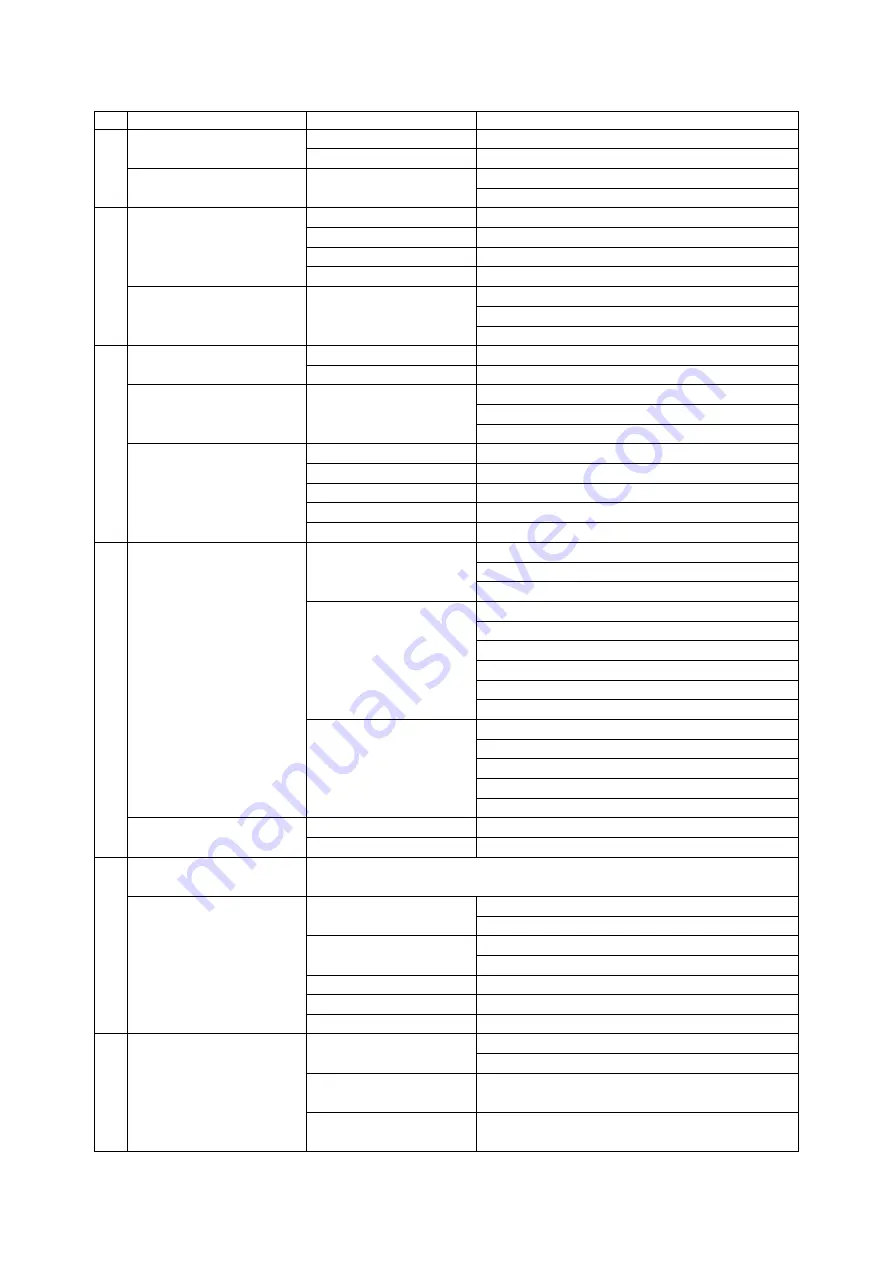

State

Malfunction occurrence

Abnormal point

Possible cause

E. Defrosting is operated

q

No trouble with the unit Excessive amount of moisture in cargo

frequently.

w

Defrost timer

Short setting timer

F. Refrigeration unit is

q

Container

High cargo temperature

normal

Poor thermal insulation or air leakage

A. Discharge pressure

q

Poor compression of compressor Abrasion of scroll slide section

is low.

w

Hot gas solenoid valve Not open

e

Defrosting solenoid valve Not open

r

Injection solenoid valve

Valve blocked with contamination

B. Discharge pressure is

q

Evaporator fan

Damages on fan blade

high

Rotation failure of fan motor

Actuation of fan motor thermal protector

A. Hunting

q

Suction modulating valve Valve blocked with contamination

w

Electronic expansion valve Valve blocked with contamination

B. Temperature

q

Suction modulating

Valve blocked with contamination

continues dropping.

valve

Magnetic coil malfunction

Wire breakage

C. Temperature

q

Suction modulating valve Valve blocked with contamination

continues rising.

w

Electronic expansion valve Valve blocked with contamination

e

Evaporator

Insufficient evaporator air flow rate ( Refer to

3

-B-

y

.)

r

Drier

Drier blocked with contamination

t

Shortage of refrigerant charging amount

Refrigerant leakage

A. Abnormal noise is

q

Compressor

Worn-out of bearing

generated

Abrasion of scroll slide section

Loose-tightened bolt

w

Evaporator fan

Loose fan motor set bolt

Deformation of fan motor set leg or loose-tightened bolt

Bending of fan motor shaft

Worn-out of fan motor bearing

Deformation of fan guide

Contact between fan and fan guide

e

Condenser fan

Loose-tightened fan motor set bolt

Bending of fan motor shaft

Worn-out of fan motor bearing

Deformation of fan guide

Deformation of condenser front panel

B. Abnormal vibration

q

Compressor

Loose-tightened set bolt

generates

w

Piping

Loose-tightened or missing of clamp bolt

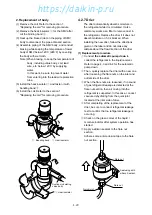

Frosting area is less than

It is normal, since the unit is controlled to make superheat degree small

one third of compressor surface.

by electronic expansion valve.

Frosting area is

Suction gas temperature sensor Defective contact of sensing section

more than one third of

Deviation from specified sensor characteristics

compressor surface.

Discharge gas

Defective contact of sensing section

temperature sensor

Deviation from specified sensor characteristics

Evaporator inlet sensor

In back-up operation due to faulty sensor

Evaporator outlet sensor

In back-up operation due to faulty sensor

Electronic Expansion valve Valve blocked with contamination

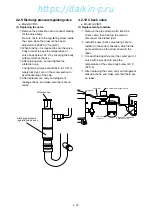

Although water coupling

q

No actuation of water Insufficient cooling water flow rate

are connected,

pressure switch

Water pressure switch malfunction

condenser fan continues

w

No trouble with

To prevent temperature in the control box from rising,

rotating.

the unit

the condenser fan rotates at CBS of 59˚C or higher.

e

Refrigerant over

Condenser fan is operating due to abnormal high

charged

pressure caused by refrigerant over charged

4

Inside

temperature

does

not

rise

(in

the

heating

m

ode)

5

Control

is

u

nstable

6

Abnormal

n

oise

or

abnormal

vibration.

8

Water-cooled

operation

is

impossible

7

Abnormal

frosting

on

compressor

3

Inside

temperature

does

not

drop.

https://daikin-p.ru

Содержание LXE10E-1

Страница 161: ...7 9 https daikin p ru ...

Страница 162: ...7 14 Schematic wiring diagram LXE10E 1 7 10 https daikin p ru ...

Страница 163: ...7 15 Stereoscopic wiring diagram LXE10E 1 7 11 https daikin p ru ...