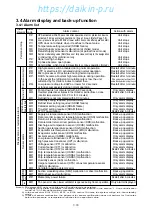

No.

Inspection item

Inspection content

PTI

2

nd

year 4

th

year 8

th

year

1

Inspection for physical damage

1) Casing frame

2) Compressor

3) Condenser fan motor

2

Loose mounting bolts

4) Evaporator fan motor

5) Control box

6) Temperature recorder box

7) Access panel

8) Others

3

Conditions of panel,

hinge and lock

4

Drain pan and drain hose

cleaning

1) Cover packing inspection and replacement

5

Control box inspection

2) Loose cable gland

3) Internal cleaning

6

Temperature recorder box

1) Cover packing inspection and replacement

inspection

2) Internal cleaning

7

Sealing condition of holes

1) Air leakage and clearance

through casing frame

8

Packing inspection and

1) Ventilator cover packing

replacement

2) Unit sealing packing

1) Compressor

9

Painted area recondition

2) Water-cooled condenser/liquid receiver

3) Solenoid valve (coil cap)

4) Casing frame

1) Compressor

10

Repainting

2) Water-cooled condenser/liquid receiver

3) Condenser fan motor

4) Condenser fan

1

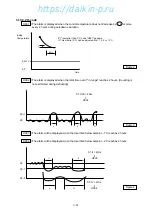

Gas leakage

1) Inspection of moisture in the refrigerant,

2

Refrigerant

and refrigerant charged amount

2) Replacement of refrigerant

Inspection of high pressure

3

switch operational pressure

1) Liquid solenoid valve

2) Economizer solenoid valve

Operation and leakage

3) Injection solenoid valve

4

of solenoid valve

4) Hot gas solenoid valve

5) Defrosting solenoid valve

6) Discharge gas by-pass solenoid valve

Operation and leakage of

5

suction modulating valve

Operation and leakage of

6

electronic expansion valve

7

Compressor

Water entering to compressor terminal

3-46

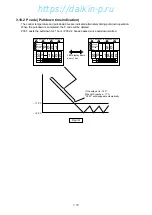

3.9.1 Inspection item

The periodic inspection and adjustment of components (if required) is recommended to ensure

continued successful operation.

The following table shows an example of the inspection plan.

Refrigerant

system

General

s

tructure

https://daikin-p.ru

Содержание LXE10E-1

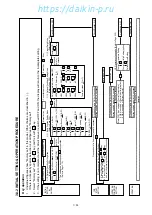

Страница 161: ...7 9 https daikin p ru ...

Страница 162: ...7 14 Schematic wiring diagram LXE10E 1 7 10 https daikin p ru ...

Страница 163: ...7 15 Stereoscopic wiring diagram LXE10E 1 7 11 https daikin p ru ...