NRQ=çÑ=NSQ

fåëíêìÅíáçå=j~åì~ä=^ìêáÖ~=`çãé~Åí=ÉåMP

NMK=m~êíë=~åÇ=íççäë

fãéçêí~åí=ëé~êÉ=é~êíë

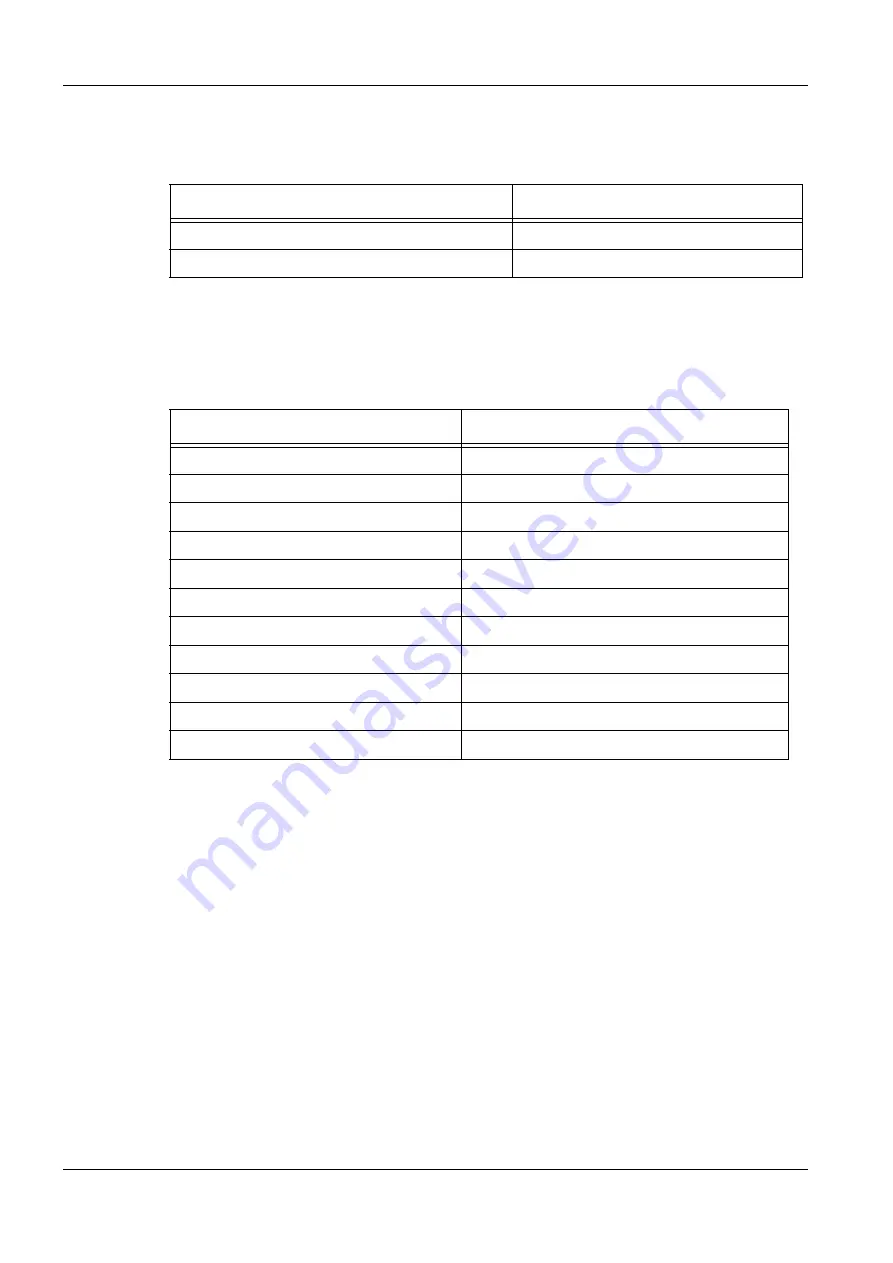

10.2. Important spare parts

10.3. Tools and accessories

Item

Part no.

Set of fuses

348200-8801-000

Chamber door o-ring

113-880

Item

Part no.

3 mm Allen key

0015-247

1.5 mm Allen key

151-883

Small pliers

-

Sample holders

Refer to sample holder catalogue.

Stubs

-

Tweezers

-

TEM oil 300

0484-955

Isopropanol

-

Cloth, lint-free

-

Gloves, lint-free

-

Aluminium foil or antistatic bag

-

Summary of Contents for AURIGA Compact Crossbeam

Page 1: ...AURIGA Compact Crossbeam workstation Instruction Manual ...

Page 50: ...RM çÑ NSQ fåëíêìÅíáçå j åì ä ìêáÖ çãé Åí ÉåMP PK aÉëÅêáéíáçå ìëíçãÉê ëÉêîáÅÉ ...

Page 54: ...RQ çÑ NSQ fåëíêìÅíáçå j åì ä ìêáÖ çãé Åí ÉåMP RK fåëí ää íáçå ...

Page 150: ...NRM çÑ NSQ fåëíêìÅíáçå j åì ä ìêáÖ çãé Åí ÉåMP UK qêçìÄäÉëÜççíáåÖ mçïÉê ÅáêÅìáí ...

Page 156: ...NRS çÑ NSQ fåëíêìÅíáçå j åì ä ìêáÖ çãé Åí ÉåMP NNK ÄÄêÉîá íáçåë ...

Page 160: ...NSM çÑ NSQ fåëíêìÅíáçå j åì ä ìêáÖ çãé Åí ÉåMP NPK aÉÅä ê íáçå çÑ ÅçåÑçêãáíó ...