4-1

Positional Deviation Measurement

4

Chapter 4: Positional Deviation Measurement

[Measurement results]

Center coordinates: (X2, Y2)

Amount of deviation: X2-X1, Y2-Y1

The gray scale search function makes it possible to measure positional deviation as

well as the absolute position.

- It is possible to detect the work position with high accuracy, at a sub-pixel level.

- A rotation angle of 360

°

can be detected. (When a one point gray search is

selected).

Purpose

Examples

Application

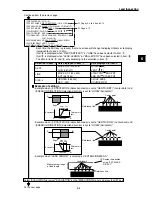

(2) 2-point search: Detection of positional deviation in X and Y directions and

angle

[Detection of the position of the substrate alignment mark (fiduciary mark)]

(1) 1-point search: Detection of positional deviation in X and Y directions

Positioning of parts and substrates

[Measurement results]

- Center coordinates of image a: (Xa2, Ya2)

- Image a positional deviation: Xa2 - Xa1, Ya2 - Ya1

- Center coordinates of image b: (Xb2, Yb2)

- Image b positional deviation: Xb2 - Xb1, Yb2 - Yb1

- Angular deviation

θ

- The angular deviation

θ

detected in the 2-point search mode will be used to correct

the rotation of the image in order to make measurements 1 to 4.

For details about rotation correction, see section 3-2, item [6] Position correction.

Search area

Y2

−

Y1

Ya2

−

Ya1

Yb2

−

Yb1

Xb2

−

Xb1

Xa2

−

Xa1

Search area (image a)

Search area (image b)

θ

: Angular deviation

X2

−

X1

Reference image: Center coordinates (X1, Y1) Inspection image: Center coordinates (X2, Y2)

θ

Reference image a: Center coordinates (Xa1, Ya1)

Inspection image a: Center coordinates (Xa2, Ya2)

Inspection image b: Center coordinates

(Xb2, Yb2)

Reference image b: Center coordinates (Xb1, Yb1)