Lead Inspection

6-1

6

Chapter 6: Lead Inspection

Purpose

Examples

Inspect the condition of IC leads and connector pins based on positional information

obtained from the gray scale search function. (No. of leads or pins that can be detected:

Max. 128 pieces)

Applications

Inspect IC leads or connector pins

Lead

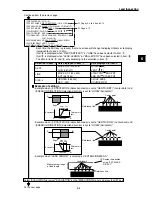

[Lead inspection]

[Inspect the layout of the IC leads and connector pins]

K0

K1

K2

K3

D1

D0

W0

W1

W2

W3

D2

L3

L0

L1

L2

Lead measure-

ment limit line

Reference line

- Inspection procedure

1

Determine the measurement points (K0 to K3) from the mid points of the leads and

the reference line.

2

Calculate the maximum and minimum distances between the leads (D0 to D2) on

the reference line.

3

Calculate the maximum and minimum lead lengths (L0 to L3), starting from the

measurement points (K0 to K3) and measuring toward the lead measurement limit

line.

4

Calculate the maximum and minimum lead widths (W0 to W3) from the measure-

ment points.

- Number of leads K

- D0 to D2: Distance

between leads

- W0 to W3: Lead width

- L0 to L3: Lead length