16-3

PC Function

16

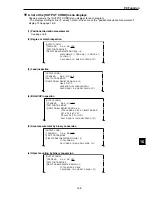

16-2 Ladder circuit program creation

[1] Procedure for creating measurement output condition and a ladder circuit

A separate ladder circuit can be created for positional deviation measurement, degree of match

inspection, lead inspection, BGA/CSP inspection, area measurement by binary conversion, object

counting by binary conversion, object identification by binary conversion, point measurement, multiple

position measurement, and multiple degree of match inspection.

The procedure for creating a ladder circuit for positional deviation measurement is given below. A

ladder circuit can be created the same way for other measurement just change the input contact point

setting.

(1) Operation to invoke the [OUTPUT COND] menu (for positional deviation measurement : MEA-

SURE 0 CAMERA 1)

1. Move the cursor to the "POSI-DEVIATION" function on item "

4

MEASURE 0 CAM1," and select

the (MEAS-COND) item using the left and right keys. Then, press the SET key.

2. Move the cursor to item "OUT-COND" with the up, down, left and right keys, and press the SET

key.

-

The [OUTPUT COND] menu will be displayed.

3. After moving the cursor to item "

1

PAGE NO." with the up and down keys and after pressing the

SET key, specify page number "0" with the up and down keys. Set the register item to "YES" with

the left and right keys, and press the SET key.

-

Items

2

to

5

will be displayed.

A ladder circuit program can be created on each page from 0 to 4 consisting of 4 rows, each of

which has 8 terminals and 1 output relay. Therefore, a ladder circuit can be created that

consists of 20 rows in all (one row contains 8 terminals and 1 output relay). Calculations will be

carried out in the order of the page numbers 0, 1, 2, 3 and 4.

1

0

2

3

4

5

6

7

Output

Input 0

Input 1

Input 2

Input 3

Page 0

Page 1

Page 2

Page 3

Page 4

To the next page

On the MAIN OPS MENU, move the cursor to MEA-CND item, and press the SET key.

1

2

[TYPE MEAS COND]

[MEAS COND]

1

OBJECT TYPE NO.

00(0~63) NO YES

2

SELECT CAMERA

CAM1&2 CAM1&NG-IMG

3

IMG PRE-PROCESS

(TO NEXT SUB-MENU)

4

MEASURE0 CAM1

POSI-DEVIATION (MEAS-COND) NO

1

DTECT PRECISION

STANDARD HIGH

〜

〜

〜

〜

OPS-MENU RETURN LOCK EVALUATION DST&ANGL NUM-CALC OUT-COND

〜

〜

〜

〜

Row No.

Column No. 0 to 7

Ladder circuit

display area

3

3

[PAGE0]

INPUT0

LOGIC

INPUT1

LOGIC

INPUT2

LOGIC

INPUT3

LOGIC

1

0

2

3

4

5

6

7

OUT

[OUTPUT COND]

1

PAGE NO.

0(0~4) NO YES

2

SET POSITION

MOVE

3

INPUT SIGNAL

REGISTER NO.0(0~7)

MATCH M0(0~1) CRD-X0(0~1) CRD-Y0(0~1)

DEV-x0(0~1) DEV-y0(0~1) ANGL-B

CALC N00(0~15) AUX.RLY-C000(0~127)

4

LOGIC SYMBOL

DEL

5

OUTPUT SIGNAL AUX-RLY C000(0~127)

OPS-MENU RETURN LOCK

This display varies

with each

measurement

program.

-

Page

16-9 to 16-10.