STACKING INCUBATORS

Use the following procedure to stack Incubators. This work is potentially dangerous, so contact a Sanyo

representative or agent.

CAUTION

x

Select a floor that is strong enough to support the stacked incubators.

x

Never stack three or more incubators.

Doing so is dangerous.

1.

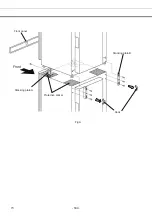

Take out two stacking plates A, two stacking plates B, four protective stickers, and four screws from

accessory bag.

Note:

When stacking two incubators,

use two stacking plates (A and B) for each one

. Only one pair of

stacking plates is provided per incubator, so take out the stacking plates (A and B) from both incubators.

Similarly only 2 protective stickers are provided per incubator

2.

Unplug both of the Incubators that are to be stacked.

3.

Remove the caps at the two places in the front of the top surface of the Incubator that is to be on the

bottom, attach the protective stickers to the four corners on the top surface of the Incubator that is to be

on the bottom. (See Fig. A.)

4.

Secure stacking plate A with the screws that are provided.

5.

Remove the front panel (5 screws) from the Incubator that is to be on the top.

6.

Place the upper Incubator on top of the lower one, being careful not to pinch your fingers.

7.

Make the lower Incubator level by adjusting the legs, and then level the upper Incubator in the same

way.

8.

Secure the stacking plate A fixed to the lower incubator to the upper Incubator with the accessory

screws.

9.

Remove from the back of the lower Incubator the two hooks (4 screws) and remove from the upper

Incubator the 2 screws on the lower rear panel.

10.

Use the 6 screws that were removed in step 9 to secure stacking plate B to the rear panels of the

upper and lower Incubators.

11.

Replace the front panel (5 screws) to the upper Incubator.

12.

Use the hooks on the back of the upper Incubator to prevent the Incubators from falling over.

- 179 -

72

Summary of Contents for MCO-19M

Page 7: ... 4 Dimensions Power cord ...

Page 16: ...Wiring diagram 13 ...

Page 17: ...Circuit diagram Main PCB 14 ...

Page 18: ... LCD PCB 15 ...

Page 110: ...MCO 19M UVH MCO 19M UV MCO 19M Multi Gas Incubator INSTRUCTION MANUAL 107 ...

Page 112: ...CONTENTS SPECIFICATIONS P 74 PERFORMANCE P 75 SAFETY CHECK SHEET P 76 109 2 ...

Page 183: ...Fig A Stacking plate B Stacking plate A Protective sticker Front panel Hook Front 180 73 ...

Page 187: ...SANYO Electric Co Ltd Printed in Japan DC3186 150B ...