- 9 -

㻌

CO

2

/O

2

zero calibration

㻌

㻌

Prior to commence calibration

z

Make sure chamber temperature should be stabilized, CO

2

sensor BOX temperature should be

45

䉝

±2

䉝

, setting CO

2

density should be 0.0% and setting O

2

density should be 20.0%.

z

Make sure there should not be left CO

2

in the chamber.

* Note) When you re-commence CO

2

calibration, outer door should be opened and make sure

there should not be left CO

2

in the chamber.

Procedure

1. Call Select Tools (1/2) screen to display Temp/CO2/O2 Calibration.

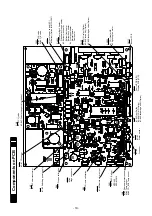

2. Turn the VR3 around CN15 on the main PCB or measure the voltages both ends of R63 to make

CO

2

sensor reference cell voltage

䠄

CO2 Zero

䠅

to 4.00V±0.03V.

3. Turn the VR2 around CN3 on the main PCB or measure the voltages both ends of R40 to make

CO

2

sensor gas cell voltage

䠄

CO2 Span

䠅

to 4.00V±0.03V.

4. Input 0.0% by pressing digit shift key and numerical value shift key and “0.1”% besides right to

the “CO2 Zero” being turned to black. (See the picture below)

5. Press MENU to call MENU display. Select OK and press ENTER key.

䣖 䣧 䣯 䣲 䢱 䣅 䣑 䢴 䢱 䣑 䢴

䣅 䣣 䣮 䣫 䣤 䣴 䣣 䣶 䣫 䣱 䣰

䢪 䢳 䢱 䢴 䢫

䣒 䣘

䣘 䣱 䣮 䣶

䣖 䣧 䣯 䣲

䣕 䣲 䣣 䣰

䢲 䢰 䢲 䤑䣅

䢵 䢹 䢰 䢲 䤑䣅

䢲 䢰 䢷 䤑䣅

䣅 䣑 䢴

䣜 䣧 䣴 䣱

䢲 䢰 䢲

䢧

䢲 䢰 䢲 䢧

䢶 䢰 䢲 䢲

䣘

䢷 䢲 䢲

䣅 䣑 䢴

䣕 䣲 䣣 䣰

䢶 䢰 䢲 䢲

䣘

䢹 䢲 䢲

䣑 䢴

䣜 䣧 䣴 䣱

䢴 䢲 䢰 䢸 䢧

䢴 䢲 䢰 䢸 䢧

䢷 䢲 䢲

䣑 䢴

䣕 䣲 䣣 䣰

䢴 䢳 䢻

䣯 䣘

䢷 䢲 䢲

䣖 䣧 䣯 䣲 䢱 䣅 䣑 䢴 䢱 䣑 䢴

䣅 䣣 䣮 䣫 䣤 䣴 䣣 䣶 䣫 䣱 䣰

䢪 䢴 䢱 䢴 䢫

䣘 䣱 䣮 䣶

䣅 䣑 䢴

䣔 䣧 䣨

䢶 䢰 䢲 䢲

䣘

䣅 䣑 䢴

䣉 䣣 䣵

䢶 䢰 䢲 䢲

䣘

䣑 䢴

䣉 䣣 䣵

䢴 䢳 䢻

䣯 䣘

Summary of Contents for MCO-19M

Page 7: ... 4 Dimensions Power cord ...

Page 16: ...Wiring diagram 13 ...

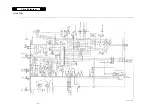

Page 17: ...Circuit diagram Main PCB 14 ...

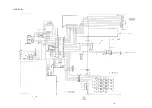

Page 18: ... LCD PCB 15 ...

Page 110: ...MCO 19M UVH MCO 19M UV MCO 19M Multi Gas Incubator INSTRUCTION MANUAL 107 ...

Page 112: ...CONTENTS SPECIFICATIONS P 74 PERFORMANCE P 75 SAFETY CHECK SHEET P 76 109 2 ...

Page 183: ...Fig A Stacking plate B Stacking plate A Protective sticker Front panel Hook Front 180 73 ...

Page 187: ...SANYO Electric Co Ltd Printed in Japan DC3186 150B ...