P/N 016-5030-020 Rev. D

65

VIPER PRO CALIBRATION AND OPERATION

SmarTrax MD system unless a technician instructs you to modify the settings. Pressing Modify PWM Settings

displays the PWM Setup screen to allow manual adjustments to the PWM values.

◦

Auto or Manual

- Toggles between automatic and manual control of the PWM values. If “Manual” is

displayed in the icon, the system is in manual mode and is no longer learning the PWM minimum values.

Pressing the button will switch SmarTrax MD to automatic mode. If “Auto” is displayed, the system is in

automatic mode and is learning the PWM minimum values. Adjusting a PWM Minimum value will switch

SmarTrax MD to manual mode. Raven Industries does not advise leaving the system in auto mode is the

PWM minimum values may change unpredictably.

◦

Left and Right Manual Steer

- Used to manually test the SmarTrax MD system. Select one of the values

or the Min or Max button to steer the machine. If it does not respond as expected, the PWM values may

need to be adjusted.

◦

Target Current

- Displays the expected current level for the mechanical drive to turn the steering wheel.

◦

Actual Current

- Displays the amount of current the system is using to steer the machine.

◦

Exit

- Returns to the System Diagnostic screen.

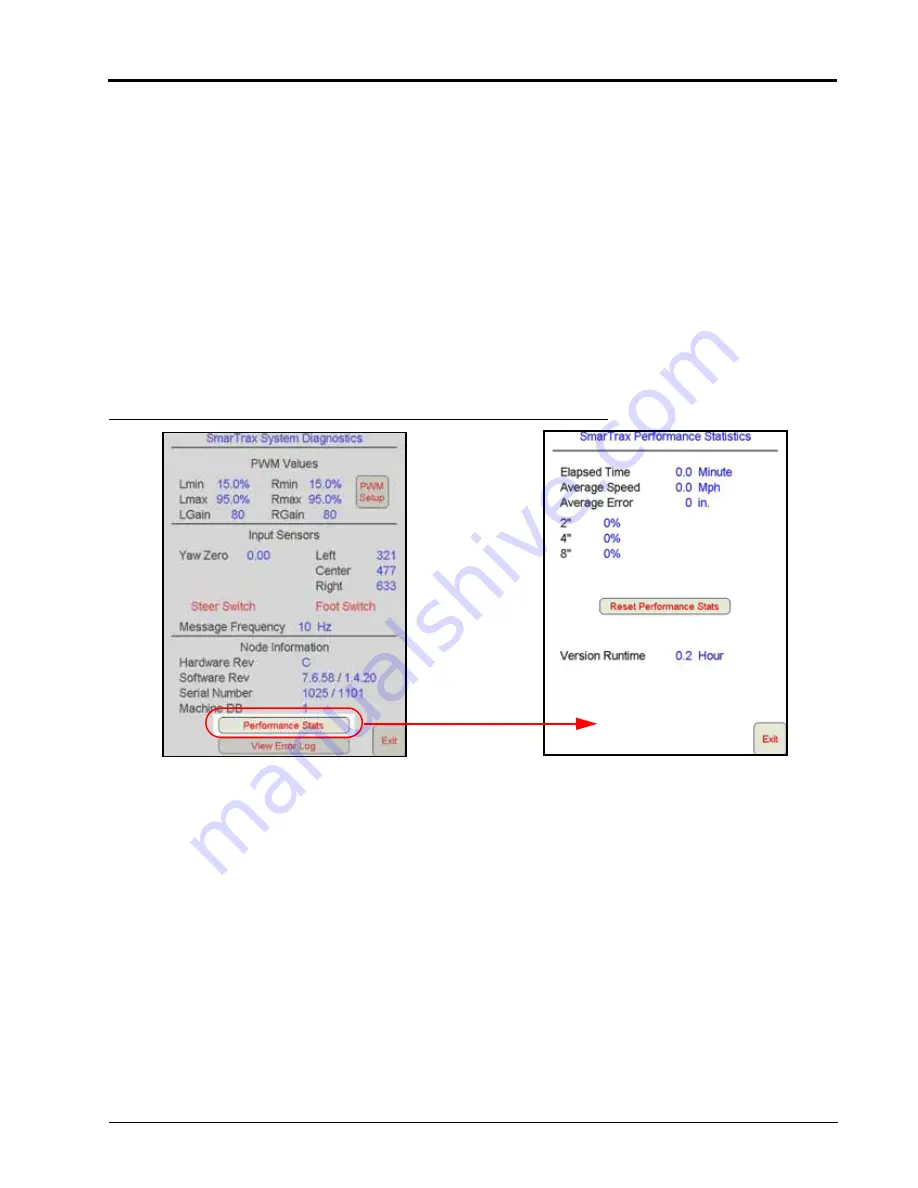

FIGURE 38. System Diagnostics and SmarTrax MD Performance Statistics Screens

•

Performance Stats

- Displays the SmarTrax MD system performance statistics.

◦

Elapsed Time

- Length of time the SmarTrax MD system has been running.

◦

Average Speed

- Average vehicle speed over the last hour while SmarTrax MD has been running.

◦

Average Error

- Average distance from the desired guidance path or line during the last hour while

SmarTrax MD has been running.

◦

1”, 2”, and 4”

- The percentage of time the machine has been within the distance of the guide line during

the last hour. Press Reset Performance Stats to set the fields to zero.

NOTE:

The error percentages are always displayed in inches, regardless of the Display Unit selection. The

equivalent metric values are 5 cm, 10 cm, and 20 cm. On non-RTK systems, the values are 2”, 4”, and

8”.

◦

Version Runtime

- The runtime of the current SmarTrax node software version.

◦

Exit

- Returns to the System Diagnostics screen.

NEED NEW

PERFORMANCE

STATISTICS

SCREEN?

Summary of Contents for SmarTrax MD

Page 6: ...Table of Contents iv SmarTrax MD Calibration Operation Manual ...

Page 10: ...CHAPTER 1 4 SmarTrax MD Calibration Operation Manual ...

Page 14: ...CHAPTER 2 8 SmarTrax MD Calibration Operation Manual ...

Page 46: ...CHAPTER 3 40 SmarTrax MD Calibration Operation Manual ...

Page 76: ...CHAPTER 4 70 SmarTrax MD Calibration Operation Manual ...

Page 112: ...CHAPTER 6 106 SmarTrax MD Calibration Operation Manual ...

Page 116: ...CHAPTER 7 110 SmarTrax MD Calibration Operation Manual ...

Page 131: ...P N 016 5030 020 Rev D 125 ROADWAY HOMOLOGATION CERTIFICATION ...

Page 132: ...CHAPTER 8 126 SmarTrax MD Calibration Operation Manual ...