NI EDIDS-2400 Series User Manual | © National Instruments | 171

CurrentPosition is not displayed on the EPT tab because it changes very rapidly.

Position Tracking

Between each crank tooth, CurrentPosition is incremented smoothly at a rate proportional to the previous crank

tooth period. In the presence of crankshaft acceleration or deceleration, sync is still properly maintained. If a new

crank tooth is received before CurrentPosition has incremented to the correct position, then CurrentPosition is

incremented at a faster rate until proper synchronization is achieved. CurrentPosition is then further incremented at

a rate proportional to the previous crank tooth period. If CurrentPosition reaches the correct position expected for the

next tooth before the tooth is received, then CurrentPosition holds its value until the next crank tooth.

EPT Function Selection

There are four EPT function selections available in the

drop-down list. Each EPT function type is

optimized for a particular range of number of crank teeth. For example, the DI Driver System provides two encoder

pattern EPT functions, each optimized for different ranges of crank tooth counts. The suggested tooth count ranges

are shown below in Table 4.11.b for each pattern type selection. The EPT function extrapolation value, which

is the single-digit suffix of each EPT_Type selection, will affect the CAD resolution of the internally calculated

CurrentPosition. The worst case resolution is 0.500 CAD for very low encoder pattern tooth counts.

For example, if using a 4-stroke 36-1 pattern, then the suggested EPT function is the “EPT N-M 7”. The “7”

component of the selection refers to the number of bits of binary extrapolation of crank angle between each crank

tooth. In this case, CurrentPosition would increment by 2^7, or 128 CAT, between each crank tooth. The range of

CurrentPosition would be from 0 to MAX_CAT = 2*36*128 = 9216. This is the total number of angular positional

ticks that are tracked by the EPT over a complete 4-stroke engine cycle. Therefore CurrentPosition will track

from 0 to 9216 and roll over to 0 at the occurrence of tooth 0. This provides an angular resolution of 0.078 CAD/

CAT. The calculated CurrentPosition is maintained with a 16-bit integer and cannot exceed 65535. Therefore,

should not exceed a value that causes

to exceed 16-bit representation. The

value is displayed on the EPT tab.

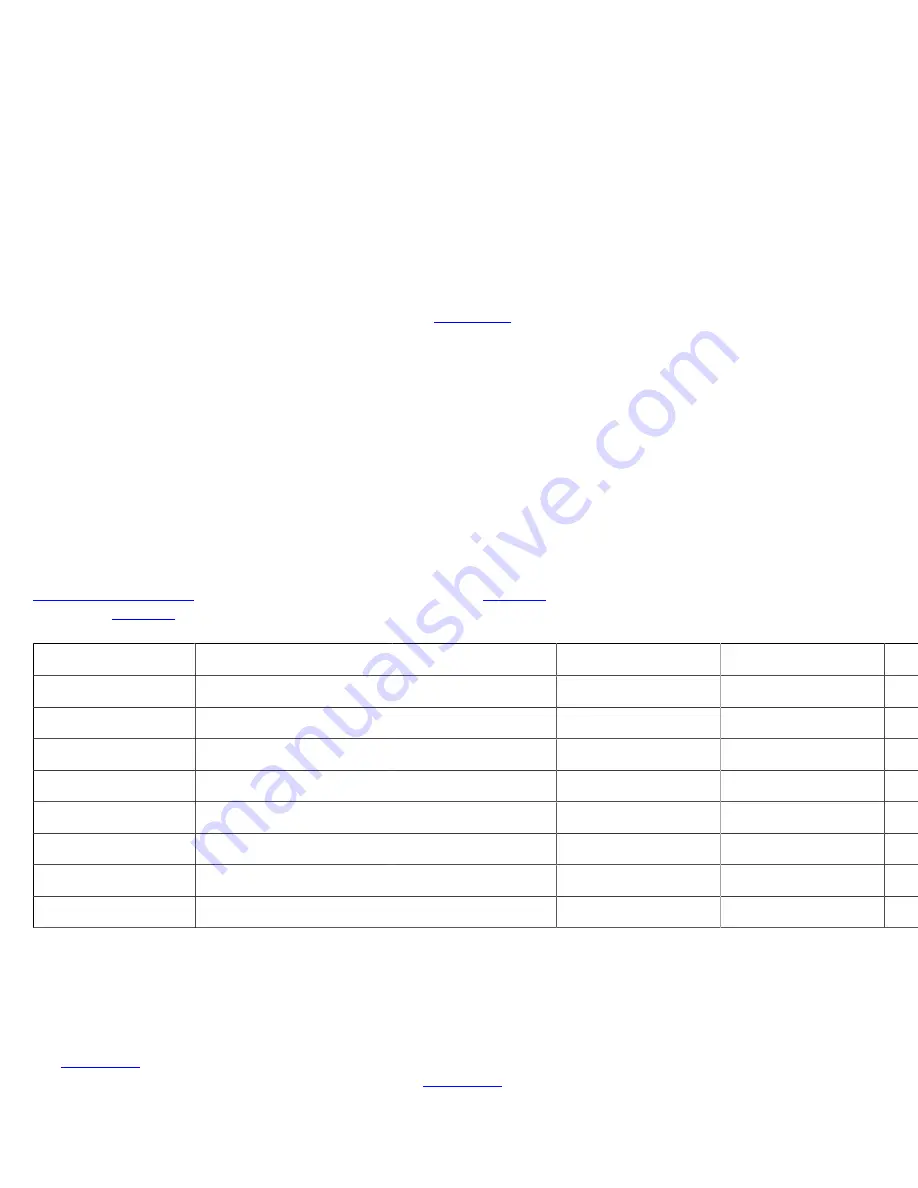

Pattern Type

NumberOfCrankTeeth

Stroke

Extrapolation

MaxCAT

CAD / CAT

EPT ENC 2 (max)

3600

4

2

28800

0.025

EPT ENC 2 (min)

180

4

2

1440

0.500

EPT ENC 4 (max)

720

4

4

23040

0.031

EPT ENC 4 (min)

45

4

4

1440

0.500

EPT N-M 7 (max)

120

4

7

30720

0.023

EPT N-M 7 (min)

12

4

7

3072

0.234

EPT N+1 9 (max)

24

4

9

24576

0.029

EPT N+1 9 (min)

4

4

9

4096

0.176

Table 4.11.b, EPT function Extrapolation Values and Suggestion Tooth Count Ranges

Loss of Sync

The EPT will lose sync under normal conditions if the crankshaft speed falls below the stall speed, as specified by

the

parameter of the EPT tab. Keep in mind that the EPT function uses a 24-bit, 40MHz timer to measure

the period between each physical tooth. Therefore, a

should be specified such that the tooth period timer

Summary of Contents for NI EDIDS-2400 Series

Page 2: ...2 ni com NI EDIDS 2400 Series User Manual...

Page 13: ...NI EDIDS 2400 Series User Manual National Instruments 13 3 2 Software...

Page 35: ...NI EDIDS 2400 Series User Manual National Instruments 35...

Page 43: ...NI EDIDS 2400 Series User Manual National Instruments 43 3 3 Hardware...

Page 48: ...48 ni com NI EDIDS 2400 Series User Manual 3 3 3 Connecting Injectors Sensors and Actuators...

Page 60: ...60 ni com NI EDIDS 2400 Series User Manual 3 3 5 b Side View of Optional Enclosure...

Page 86: ...86 ni com NI EDIDS 2400 Series User Manual See descriptions for PFI 1...

Page 241: ...NI EDIDS 2400 Series User Manual National Instruments 241 Aux PWX 2 4 See above descriptions...

Page 254: ...254 ni com NI EDIDS 2400 Series User Manual...

Page 268: ...268 ni com NI EDIDS 2400 Series User Manual...

Page 271: ...NI EDIDS 2400 Series User Manual National Instruments 271...

Page 294: ...294 ni com NI EDIDS 2400 Series User Manual...

Page 306: ...306 ni com NI EDIDS 2400 Series User Manual 22 TDK to cRIO Remote Connection...

Page 308: ...308 ni com NI EDIDS 2400 Series User Manual 8 Important Information...