5-20

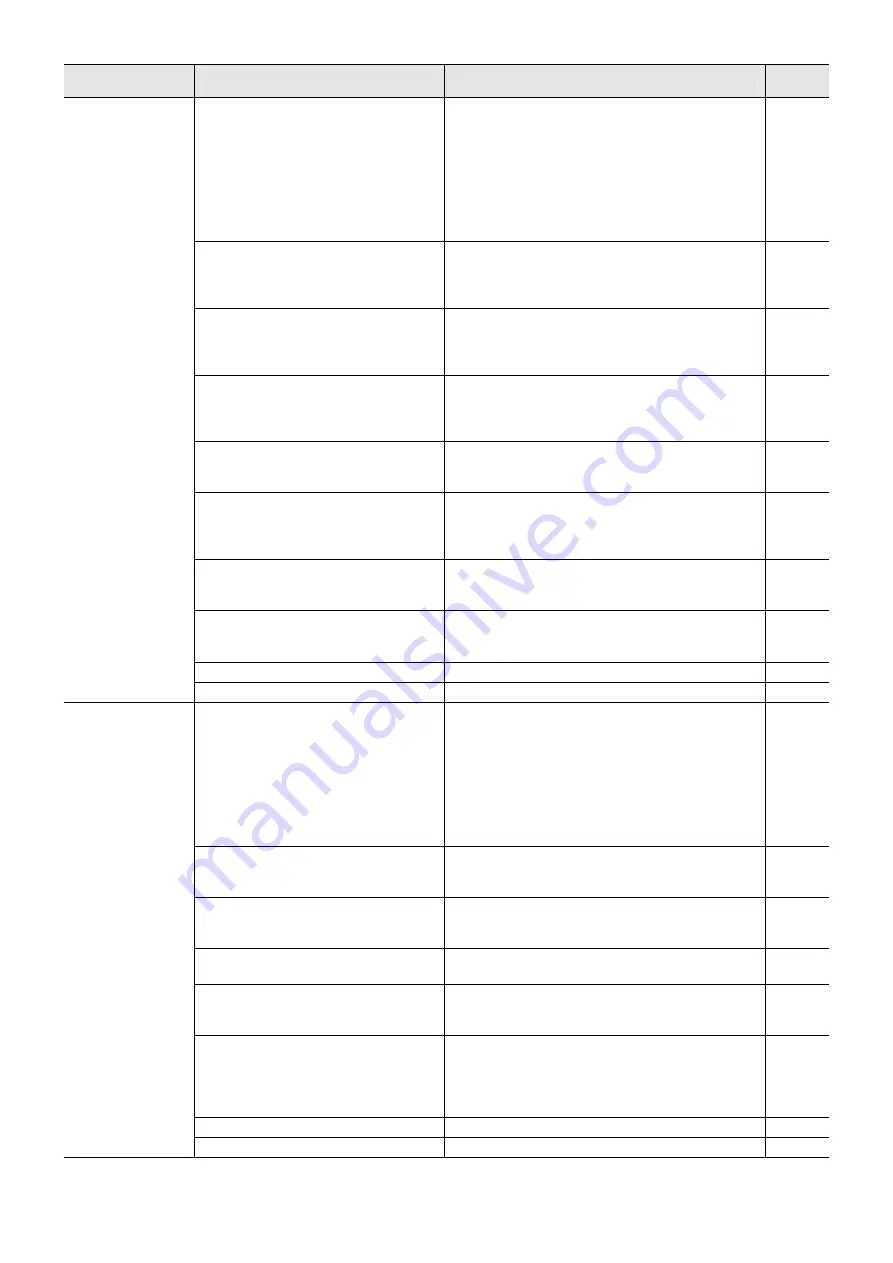

Symptom

Content of the likely cause

Countermeasures

Reference

The motor does

not operate when

the run command

is issued.

The wirings of the analogue input or

variable resistor of the frequency

command is wrong.

Correct the wirings.

• Measure the voltage between FV to SC terminal

with a tester and check that the correct voltage

is flowing if using the analogue voltage or

variable resistor input.

• Disconnect the wirings and measure the current

between current source to FI terminal with a

tester and check that the correct current is

flowing if using the analogue current input.

“51: F-TM (force terminal block)” is

assigned to the multi function input

terminal to run with the operator, and it

is in ON state.

Turn OFF the assigned terminal.

“31: OPE (force operator function)” is

assigned to the multi function input

terminal to run with the control circuit

terminal block, and it is in ON state.

Turn OFF the assigned terminal.

The inverter is tripped. (ALARM LED

lights up, and “Exxx” is displayed)

Press the STOP/RESET key to release the trip

(reset), and find the cause and perform

countermeasures from the alarm code, and then

restart.

Safety function switching switch is ON,

and either the multi function input

terminal S3/GS1, or S4/GS2 is OFF.

Turn both of the safety input GS1 and GS2 if using

the safety function. Turn the switching switch OFF if

not used.

“18: RS (reset)”, “14: CS (commercial

switch)”, “11: FRS (freelance top)” is

assigned to the multi function input

terminal, and it is in ON state.

Turn OFF the corresponding terminal.

“84: ROK (run OK signal)” is assigned

to the multi function input terminal, and

it is in OFF state.

Turn ON the assigned terminal.

There is a breakage in the wiring from

the inverter to the motor, and the

wirings within the motor.

Check the wirings.

Excessive load.

Reduce the load.

The motor is being restrained.

Release the restrain.

The rotational

speed of the motor

does not increase.

Poor contact in the analogue input or

variable resistor of the frequency

command.

Check the wirings.

• Measure the voltage between FV to SC terminal

with a tester and check that the correct voltage

is flowing if using the analogue voltage or

variable resistor input.

• Disconnect the wirings and measure the current

between voltage source to FI terminal with a

tester and check that the correct current is

flowing if using the analogue current input.

The overload restriction or the

overcurrent restriction function is

operating.

Disable the function, or raise the operation level.

The primary maximum frequency

(A004) and frequency maximum limit

(A061/A261) settings are low.

Change the settings.

Acceleration time is long

Shorten the acceleration time

(F002/F202/A092/A292).

“06: JG (jogging)” is assigned to the

multi function input terminal, and it is in

ON state.

Turn OFF the assigned terminal.

“02: CF1” to “05: CF4” are assigned to

the multi function input terminal, and is

in ON state.

Turn OFF the multi step speed setting. (If the multi

step speed setting is ON, it will run in multi step

speed operation, so it will run according to the

frequency set in the multi step speed command 1 to

15 (A021 to A035).)

Excessive load.

Reduce the load.

The motor is being restrained.

Release the restrain.

Summary of Contents for MK0003

Page 2: ......

Page 8: ...0 6...

Page 12: ...1 4 2 DIMENSIONAL DRAWING OF OUTRIGGER WIDTH...

Page 17: ...1 9 4 WORKING RADIUS LIFTING HEIGHT...

Page 18: ...1 10 Working range diagram Outrigger extended to maximum Main boom 1 section...

Page 19: ...1 11 Working range diagram Outrigger extended to maximum Main boom 2 sections...

Page 20: ...1 12 Working range diagram Outrigger extended to maximum Main boom 2 5 sections...

Page 21: ...1 13 Working range diagram Outrigger extended to maximum Main boom 3 sections...

Page 22: ...1 14 Working range diagram Outrigger extended to minimum Main boom 1 section...

Page 23: ...1 15 Working range diagram Outrigger extended to minimum Main boom 2 sections...

Page 24: ...1 16 Working range diagram Outrigger extended to minimum Main boom 2 5 sections...

Page 25: ...1 17 Working range diagram Outrigger extended to minimum Main boom 3 sections...

Page 26: ...1 18 5 RATED TOTAL LOAD CHART...

Page 32: ...2 4...

Page 33: ...2 5 1 HYDRAULIC CIRCUIT DIAGRAM 200 1176600...

Page 34: ...2 6...

Page 35: ...2 7 2 HYDRAULIC PIPING DIAGRAM 2 1 CRANE ROTATING PART 200 1171800...

Page 41: ...2 13 2 2 CONTROL LINE A...

Page 43: ...2 15 2 3CONTROL LINE B Perform spiral winding on the entire perimeter of the hose of this part...

Page 45: ...2 17 2 4 TRAVEL LINE...

Page 47: ...2 19 2 5 OUTRIGGER LINE...

Page 49: ...2 21 2 6 PT LINE 102 1152000 4...

Page 69: ...2 41...

Page 70: ...2 42...

Page 71: ...2 43...

Page 76: ...2 48 4 8 ENGINE ACCESSORIES 102 1149200...

Page 90: ...2 62 7 2 INTERNAL STRUCTURE...

Page 120: ...2 92 Part B Writing method for wire number Two places...

Page 123: ...2 95 Figure 1 Index point Figure 2 Connection diagram...

Page 166: ...2 138 15 4 APPEARANCE OF OUTRIGGER ON REAR LEFT SIDE 200 2167300...

Page 173: ...2 145 17 ELECTRIC CIRCUIT DIAGRAM 200 1176500 01...

Page 174: ...2 146 18 ELECTRIC SYSTEM 18 1 1 WIRE HARNESS OF MACHINE BODY 1 200 1172200 1...

Page 176: ...2 148 18 1 2 WIRE HARNESS OF MACHINE BODY 2 200 1172200 2...

Page 179: ...2 151 19 CONTROL ASSEMBLY 19 1 CONTROLLER 1 TTC60 Pin arrangement...

Page 180: ...2 152 TTC60 I O...

Page 181: ...2 153 2 TTC36X Pin arrangement...

Page 182: ...2 154 TTC36X lower part I O...

Page 209: ...2 181 19 2 5 LIST OF CONTROLLER INPUT MONITORING...

Page 210: ...2 182 19 2 6 LIST OF CONTROLLER ANALOG INPUT OUTPUT MONITORING...

Page 245: ...3 9 1 2 3 ANGLE METER 360 S200M3297000...

Page 274: ...3 38...

Page 293: ...4 19 8 SERVICE LOCATIONS...

Page 294: ...4 20...

Page 296: ...5 2 1 ELECTRICAL MOTOR UNIT ASSEMBLY Unit weight 180 kg...

Page 324: ...5 30...

Page 325: ...5 31 4 ELECTRICAL DIAGRAM S200M3122000 01...

Page 326: ...5 32 S200M3122000 02...

Page 336: ...6 8 1 3 2 INTERNAL STRUCTURE OF WINCH MOTOR...

Page 345: ...6 17 4 WORKING RADIUS LIFTING HEIGHT OF ONE FALL WINCH...

Page 348: ......